For all my tree loving friends.

A University of Canterbury professor is researching ways we can 3D print wood. Could this be how we save our trees?

My friends at ORN setting records again.

Researchers at the Oak Ridge National Laboratory broke a world record for the largest solid 3D-printed item with its trim-and-drill tool. The item, which is practically the size of a large SUV, took 30 hours to print using carbon fiber and composite plastic materials.

Using light, a team of MIT researchers were able to print 3D structures that “remember” their original shapes. Even after being stretched, twisted, and bent at extreme angles, the structures sprang back to their original forms within seconds of being heated to a certain temperature “sweet spot.”

Beyond 3D-printed dinners, additive manufacturing has helped create artificial jaws, better prosthetics, and even brain tumors. Researchers at MIT have found a way to print 3D structures that remember their original shapes within seconds of being heated at a specific temperature “sweet spot,” paving the way towards developing tiny drug capsules that open upon early signs of infection.

Researchers often turn to 3D printing to fabricate shape-memory structures since the technology lets them to custom-design structures with relatively fine detail. The only problem is that conventional 3D printers come with size restrictions—the structures’ details can’t go any smaller than a few millimeters, and the restriction limits how fast the material can recover its original shape.

We now have 3D-printers that don’t need any electricity.

This could be bad news for some companies.

Many people love the flexibility of building their PC. They know that they can say what they want, how they want it. Each individual component in the PC can be customized to how the user wants it. Some people build them to achieve the top specifications while others will build them as cheaply as possible as are on a budget. Whatever the reason for building a PC, a little help has now been offered by ASUS, which will allow you to use 3D printing to print simply the components you need.

What ASUS plans to do is provide CAD files to customers to use their 3D printer to print their very own motherboard components. But, the printing is more for aesthetic reasons rather than anything else. The idea behind it is that consumers will be able to create a personalized look for their motherboard, or print other components in a particular color. Some suggestions also include being able to print company logo’s on parts also.

Art imitated in life again.

A 3D-printed, 20-foot Stargate portal replica is the centerpiece of a new exhibition at Belgium’s Musée royal de Mariemont.

Technology can be confusing when it begins moving at such an accelerated rate, perfectly exemplified by the 3D industry, and encompassing all that goes with it, from 3D scanning to 3D printing and then peripheral industries that are often connected too such as augmented and virtual realities. We’ve barely digested all the stunning innovations making impacts in so many different sectors, from 3D printed medical models that allow for more complex surgeries, to 3D printed parts for a suspension system that make racing bikes go faster, all the way to incredible toys for your kids using augmented reality systems.

Technology can be confusing when it begins moving at such an accelerated rate, perfectly exemplified by the 3D industry, and encompassing all that goes with it, from 3D scanning to 3D printing and then peripheral industries that are often connected too such as augmented and virtual realities. We’ve barely digested all the stunning innovations making impacts in so many different sectors, from 3D printed medical models that allow for more complex surgeries, to 3D printed parts for a suspension system that make racing bikes go faster, all the way to incredible toys for your kids using augmented reality systems.

Yet, while work is definitely just beginning in the 3D realm, scientists have already begun exploring a range of uses for 4D technology that should prove offer impacts in just as many applications, from the medical field to electronics and far beyond. It might seem like a lot all at once, but the two technologies definitely work together, with the 4D emphasis adding a more intuitive, smart angle to fabrication.

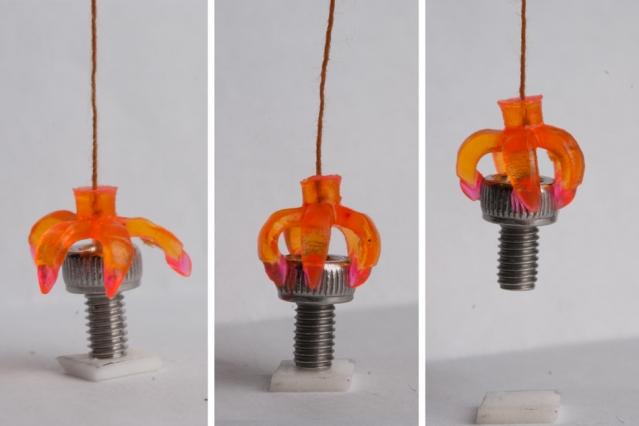

As we’ve seen in other studies using the application of heat, it would appear that 3D printed objects can be treated or manipulated to cause shapes to morph according to their environment, as well as remembering their previous state and going back to it in the appropriate conditions. Now, teams from both MIT and the Singapore University of Technology and Design (SUTD) are employing light in their endeavors to create smart structures. They’ve had good success too, if the amount of torturing they’ve put these materials through is any indication. According to the engineers, they’ve twisted, bent, and stretched everything from small coils to flowers fabricated out of numerous materials, and even a replica they made of the Eiffel tower. As is the case with structures being pushed into the 4D realm, all of the above materials reverted.

A team of Lawrence Livermore National Laboratory researchers has demonstrated the 3D printing of shape-shifting structures that can fold or unfold to reshape themselves when exposed to heat or electricity. The micro-architected structures were fabricated from a conductive, environmentally responsive polymer ink developed at the Lab.

In an article published recently by the journal Scientific Reports (link is external), Lab scientists and engineers revealed a strategy for creating boxes, spirals and spheres from shape memory polymers (SMPs), bio-based “smart” materials that exhibit shape-changes when resistively heated or when exposed to the appropriate temperature.