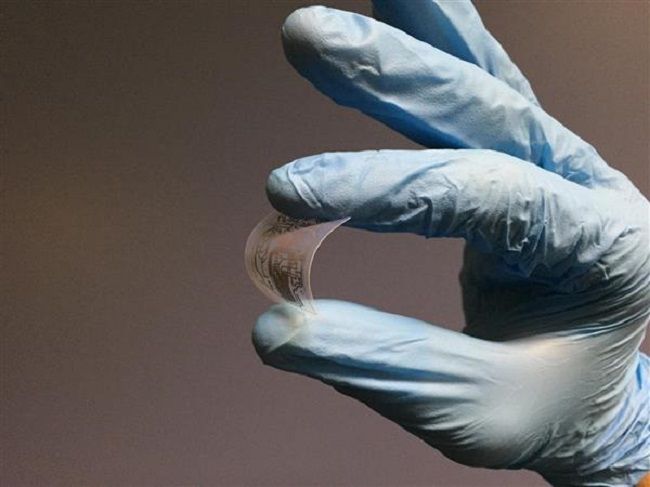

This 3D-printed cast only takes an hour to make!

Category: 3D printing – Page 120

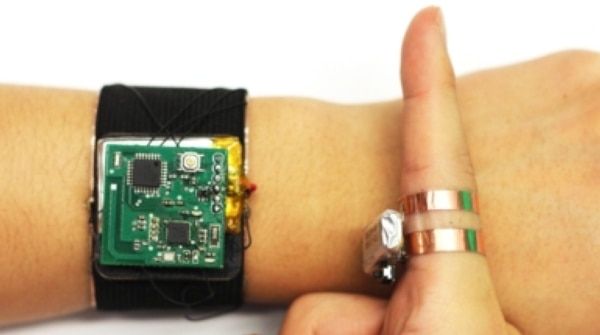

Cheap and Useful 3D Printed Electronics

Nice.

Shopping trends change from time to time while consumers continue to search for more affordable products with better functionality and specs. Researchers and developers around the world continue to improve company products while lessening the cost of producing these materials.

Gadgets like smartphones, LED lights, tablets and solar cells are already part of the mainstream, and it is not going to change anytime soon. Companies that are involved in this industry must always keep a competitive edge against other manufacturers.

Lockheed Martin Submits Patent for 3D Printed Synthetic Diamond

Check it out! Finally! Now get ready to mass produce synthetic diamonds for QC, medical tech, etc.

Every additive manufacturing (AM) system offers the potential for endless creativity. As designers learn to embrace the possibilities offered by digital design and AM, the number of applications for the technology increases. Everything has its limits, however, and for AM those limits are sometimes related to materials.

3D printing has already come a long way from the days when it was primarily a plastic process. You can find AM systems that print in wood, ceramics, metal and much, much more. According to a patent filed with the US Patent & Trademark Office, Lockheed Martin may be developing a method that will add synthetic diamond to that list.

Ban Ki-moon: ‘digital technologies like 3D printing have the potential for massive destruction’

More on the UN’s concern on the next gen technologies.

UN Photo/Rick Bajornas

Of all the initiatives and developments in the 3D printing world, none have caused as much headaches as 3D printed guns. And regardless of where you stand on the issue of gun rights in America, it’s no secret that completely untraceable plastic guns are bringing security issues to the table. Especially law makers in the US have been scratching their heads about what to do with them. Among others, the US State Department has been trying to limit the spread of 3D printable gun designs, while a new law passed in California last month requires 3D printed guns to be registered.

But the issue of 3D printed guns transcends second amendment debates, according to UN Secretary-General Ban Ki-moon. During a speech on the global proliferation of weapons, he listed 3D printing alongside a number of technologies that can be used by terrorists and that facilitate the production of weapons of mass destruction (WMDs) and other biological and technological threats.

World not prepared for biological attacks, new technology threats: Ban Ki-moon

CISO & CSO at many companies are certainly going to have their work cut out for them in the long-term future as more and more new tech such as 3D Printing, Synthetic Bio, etc. are adopted into companies; really brings a new level of security concerns not only in government; but also the private sector.

He pointed out that while there were international organisations to prevent the spread of nuclear and chemical weapons, there was no such agency to deal with biological weapons.

Speaking at the Council debate on weapons of mass destruction (WMD), he sought to expand its definition beyond nuclear, chemical and biological to embrace the threats arising from 21st century science, technology and globalisation.

Information and communication technologies, artificial intelligence, 3D printing and synthetic biology have the potential massive destruction, he said. “The nexus between these emerging technologies and WMD needs close examination and action.”

Accessible Synthetic Biology Raises New Concerns for DIY Biological Warfare

Good; glad they are hearing us. Because it is a huge issue for sure especially with some of the things that I seen some of the researchers proposing to use CRISPR, 3D Printers, etc. to create some bizarre creatures. Example, in March to scientists in the UK wanted to use CRISPR to create a dragon; personally I didn’t expect it to be successful. However, the scientists didn’t consider the fallout to the public if they had actually succeeded.

For a few hundred dollars, anyone can start doing genetic editing in the comfort of their own home.

Scientists are working on a real-life Star Trek phaser

Want to be the next Captain Kirk or Spock; we’re getting more close of being a Star Trek & Star Wars world with drones and fighter jets with death lasers, cyborgs with BMI technology, sabers being developed, and now the Star Trek phaser is being developed.

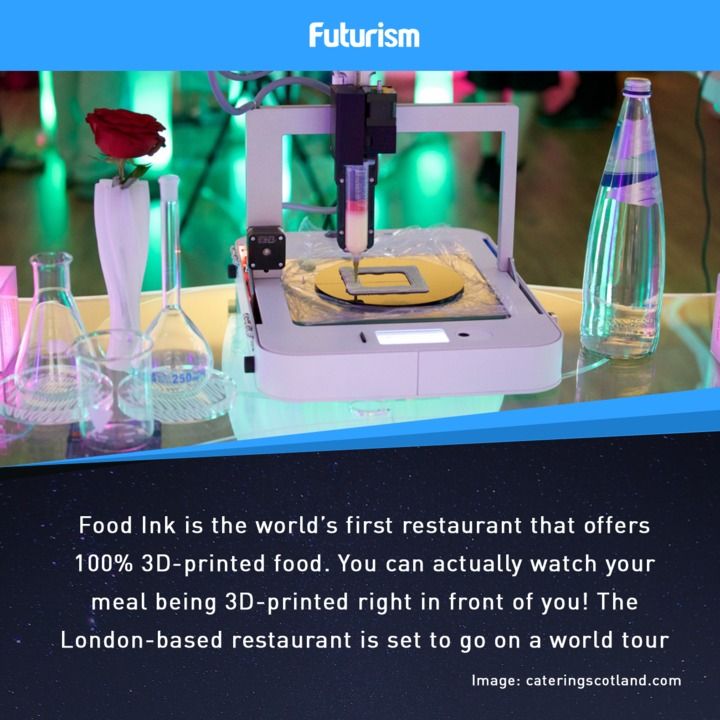

Every year Star Trek’s futuristic sci-fi technology comes closer to just being “technology.” We live in a world where video chats, communicators, and real-time translators are normal, where androids are becoming more and more realistic and food replicators are almost here thanks to 3D printing. The next step? Phasers!

Next month the Smithsonian Channel will air a two-hour Star Trek special to celebrate the show’s 50th Anniversary, which will take a look at some of the technologies the show predicted. In this just-released segment of Building Star Trek, future phaser use is predicated by laser scientist Rob Afzal of Lockheed Martin who, let’s be honest, has one of the coolest titles in the world. (“What do you do?” “I’m a LASER SCIENTIST.”)

The Force is most definitely with this ultra-detailed 3D-printed lightsaber

Want your own lightsaber? with this printer you can have your own.

This 3D-printable custom lightsaber is truly a thing of beauty. Here’s how you can make your own.