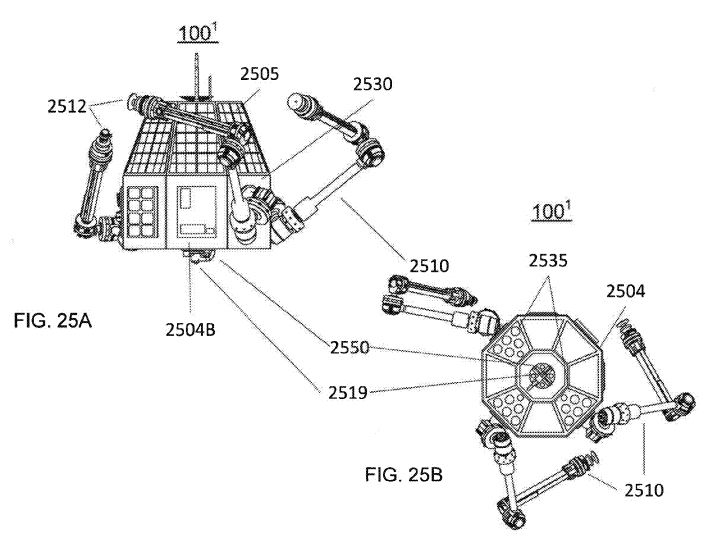

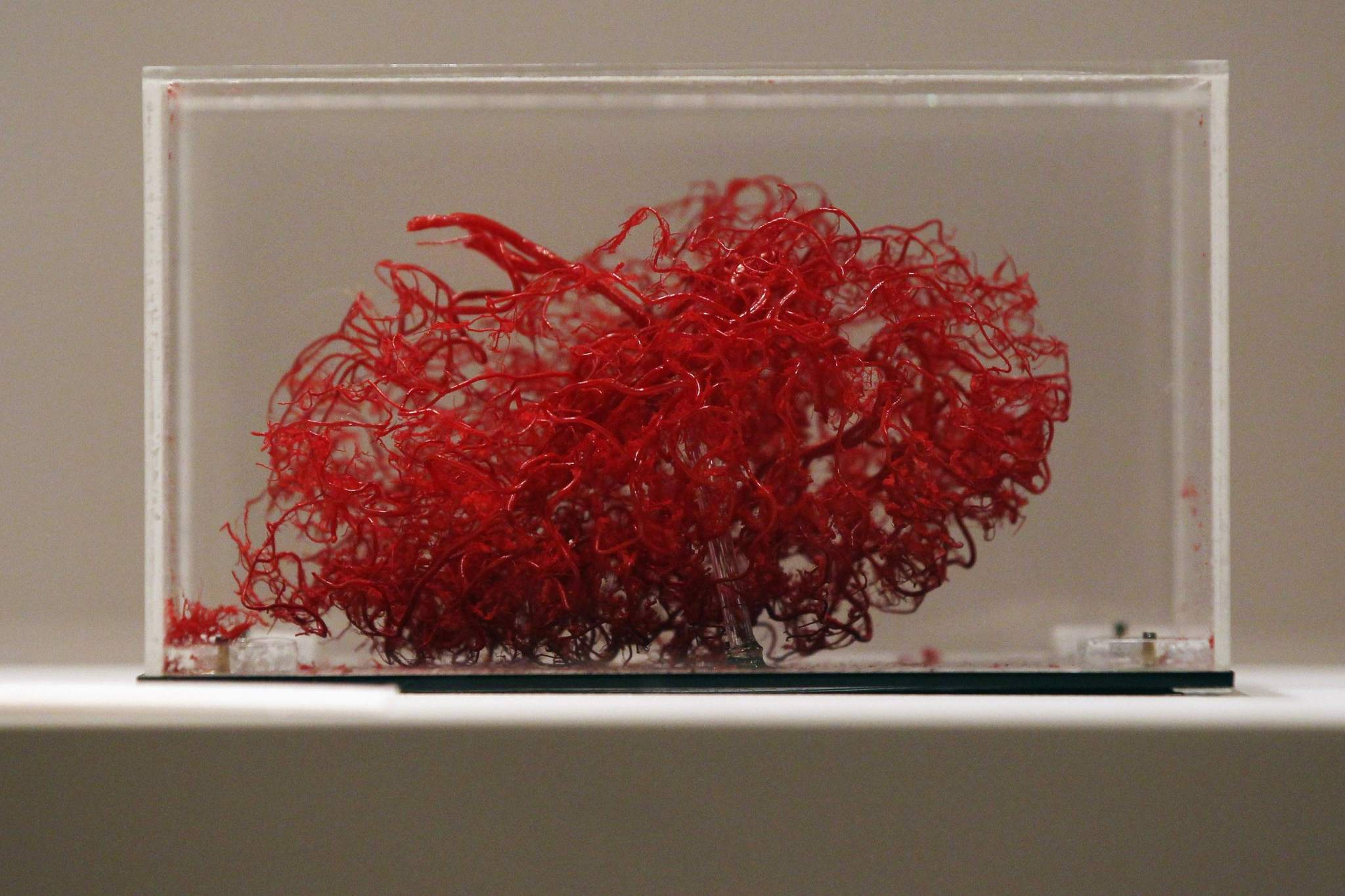

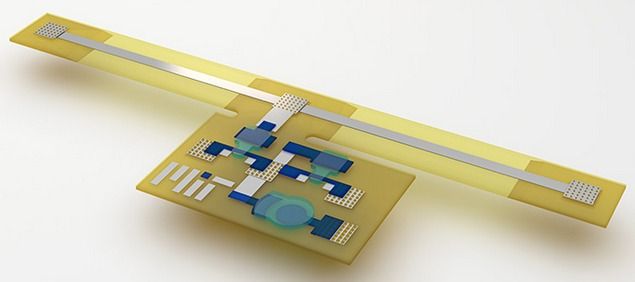

Illustration of 3D-printed sensory composite (credit: Subramanian Sundaram)

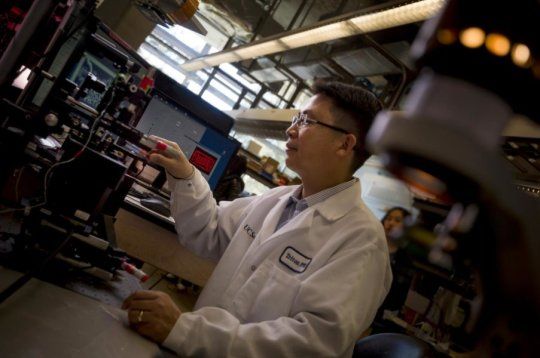

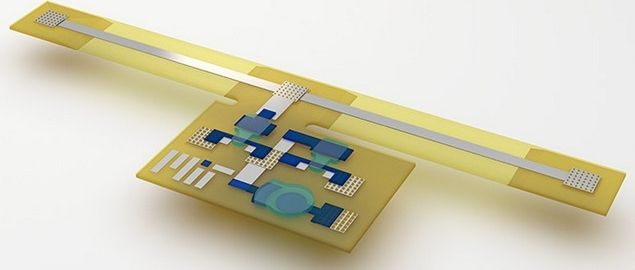

MIT researchers have designed a radical new method of creating flexible, printable electronics that combine sensors and processing circuitry.

Covering a robot — or an airplane or a bridge, for example — with sensors will require a technology that is both flexible and cost-effective to manufacture in bulk. To demonstrate the feasibility of their new method, the researchers at MIT’s Computer Science and Artificial Intelligence Laboratory have designed and built a 3D-printed device that responds to mechanical stresses by changing the color of a spot on its surface.

Illustration of 3D-printed sensory composite (credit: Subramanian Sundaram)

Illustration of 3D-printed sensory composite (credit: Subramanian Sundaram)