Bioprinting new organs and tissues could make transplants available and affordable for all, but is still decades away. In the meantime, scientists have re-purposed the technology to 3D print biocompatible high-precision silicone implants instead.

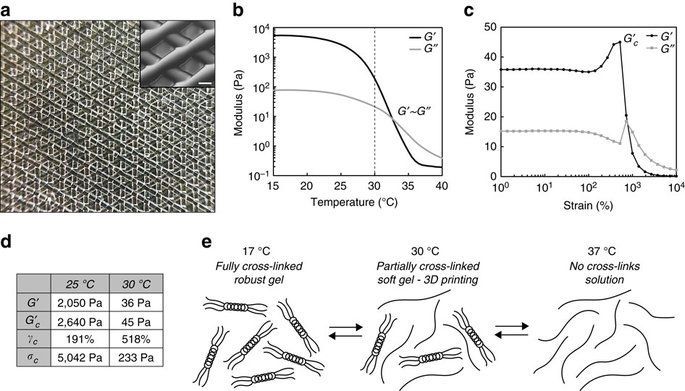

Soft materials like biological material or silicone are difficult to 3D print because they can’t support themselves like the more rigid plastics typically used by 3D printers. In 2015, Tommy Angelini’s lab at the University of Florida developed a new way of 3D printing soft materials by injecting them into a granular gel similar to hand sanitizer that supports them as they are deposited.