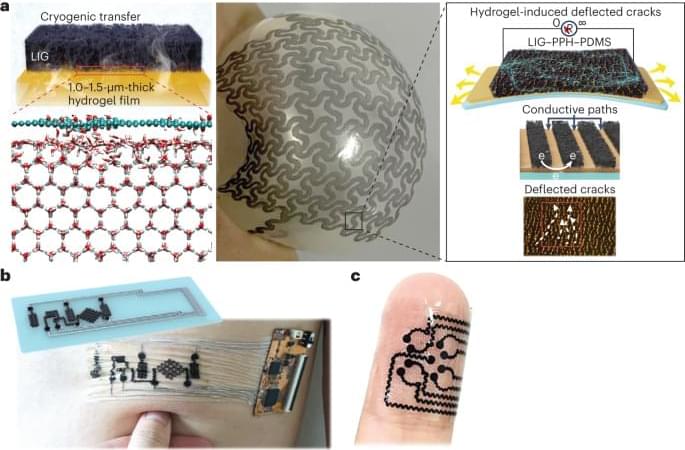

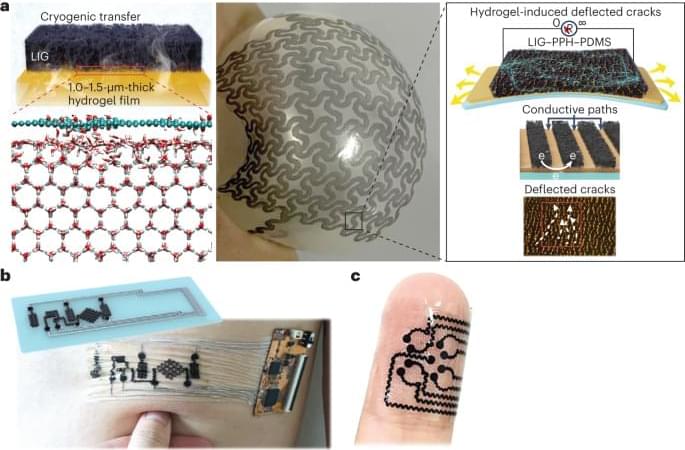

By transferring laser-induced graphene to a hydrogel film at cryogenic temperatures, stretchable graphene–hydrogel interfaces can be created for application in wearable and implantable electronics.

A new way to experience adventure and challenge your limits.

Do you love exploring the great outdoors, but feel limited by your physical stamina or the weight of your backpack?

A robot startup, Hypershell from Y-Combinator China, has created an all-terrain exoskeleton that will take your outdoor adventures to the next level.

A recent study published in Nature Electronics discusses stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics.

Stretchable and conductive nanocomposites with mechanically soft, thin and biocompatible features play vital roles in developing wearable skin-like devices, smart soft robots and implantable bioelectronics.

Although several design strategies involving surface engineering have been reported to overcome the mechanical mismatch between the brittle electrodes and stretchable polymers, it is still challenging to realize monolithic integration of various components with diverse functionalities using the current ultrathin stretchable conductive nanocomposites. This is attributed to the lack of suitable conductive nanomaterial systems compatible with facile patterning strategies.

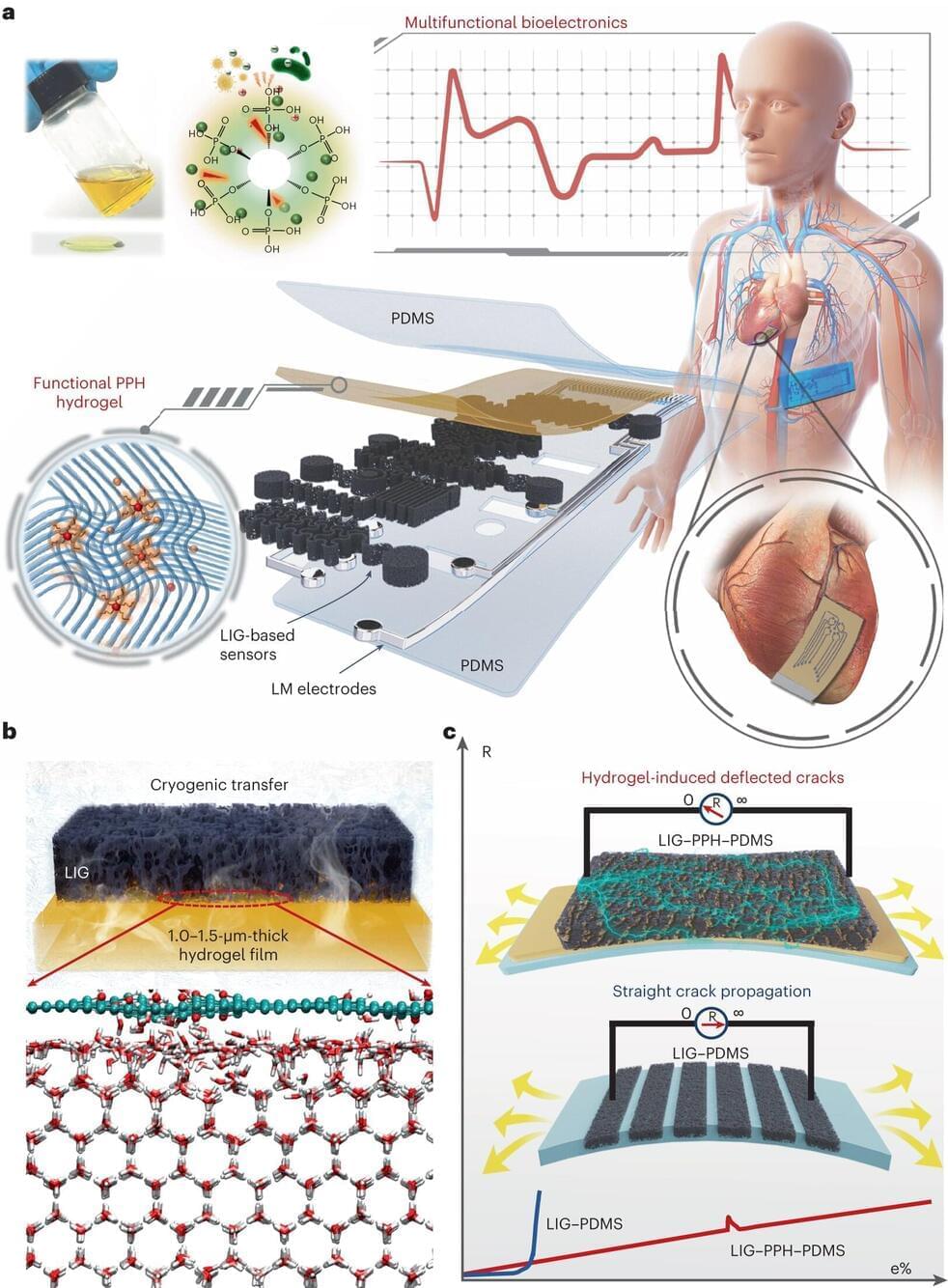

Soft robots, medical devices, and wearable devices have permeated our daily lives. KAIST (Korea Advanced Institute of Science and Technology) researchers have developed a fluid switch using ionic polymer artificial muscles that operates at ultra-low power and produces a force 34 times greater than its weight. Fluid switches control fluid flow, causing the fluid to flow in a specific direction to invoke various movements.

KAIST announced on the 4th of January that a research team under Professor IlKwon Oh from the Department of Mechanical Engineering has developed a soft fluidic switch that operates at ultra-low voltage and can be used in narrow spaces.

The results have been published in Science Advances (“Polysulfonated Covalent Organic Framework as Active Electrode Host for Mobile Cation Guests in Electrochemical Soft Actuator”).

The electronics industry has been in continuous development over the past decades, leading to the development, fabrication and sale of a broad range of consumer devices. In recent years, many engineers have been focusing their efforts on flexible electronics that can be used to create wearable devices, such as smartwatches, earbuds, fitness trackers, and even smart jewelry, and electronic implants for medical applications.

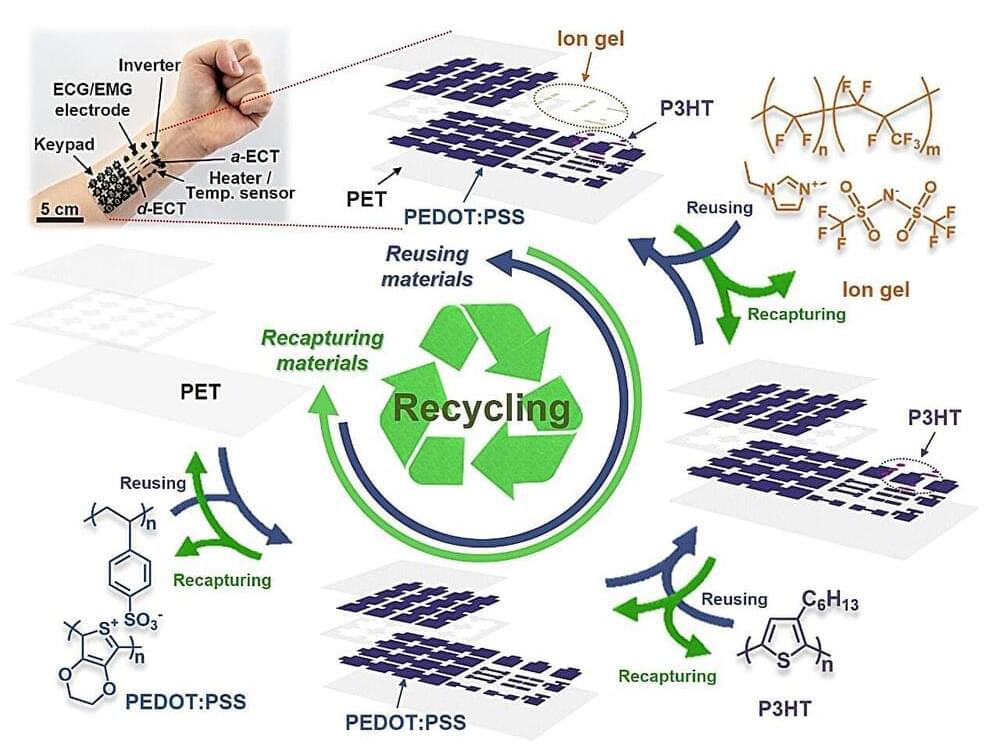

While significant progress has been made towards the development of flexible electronics, the widespread commercialization of a growing number of electronics has raised significant concerns related to their sustainability. Some research teams have thus been trying to identify environmentally-friendly materials and fabrication strategies, which could mitigate the adverse impact of the electronics industry on the planet.

Researchers at Ulsan National Institute of Science and Technology (UNIST) in South Korea recently introduced a new method to create organic and flexible electronic devices with recyclable components. This method, outlined in a paper in Nature Electronics, relies on reusable materials and eco-friendly solvents that have a minimal impact on the environment.

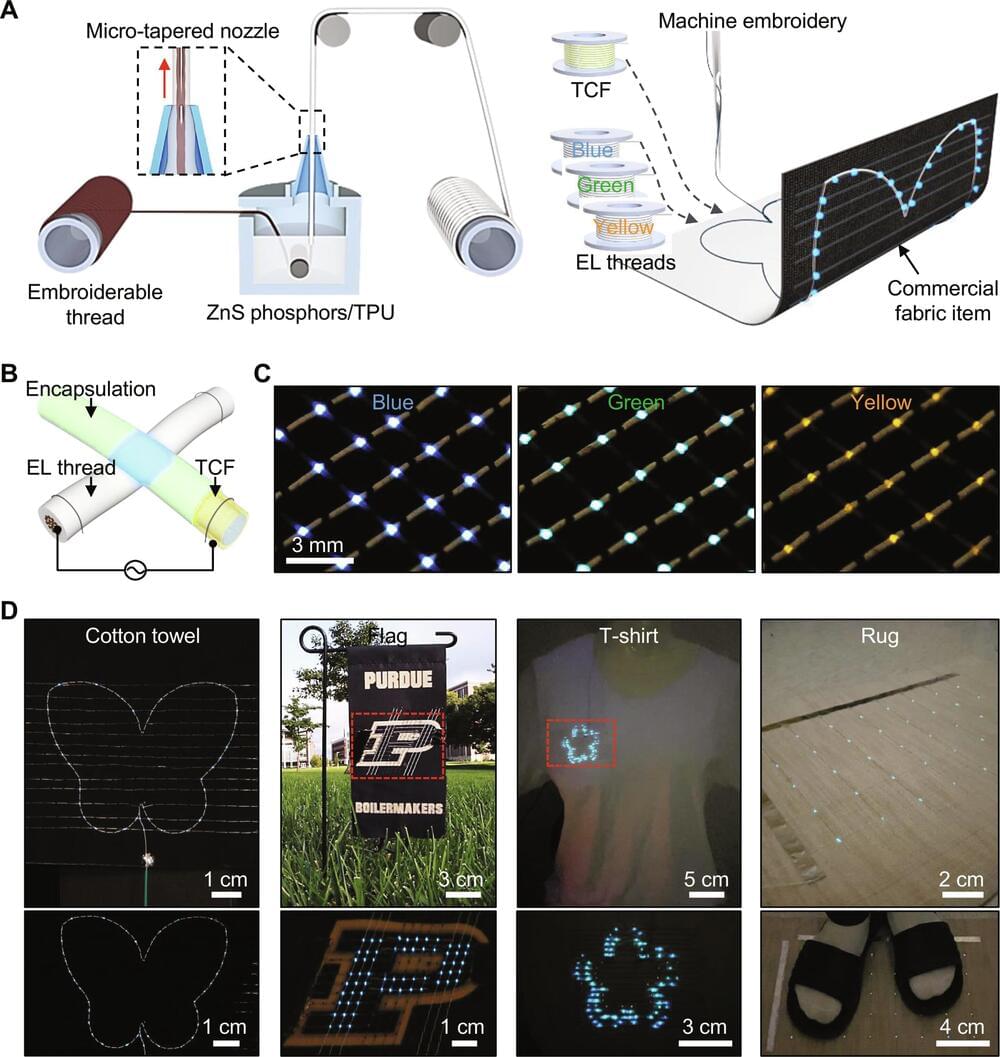

Textile research has highlighted the advances in electroluminescent threads as suitable biomaterials for driving growth in the wearable electronics market. While the direct embroidery of textiles with custom designs and patterns can offer substantial benefits, machine embroidery can challenge the integrity of these threads.

In a new report of applied science and engineering published in Science Advances, Seungse Cho and a team of scientists in biomedical engineering and medicine in the U.S., present embroiderable, multicolor, electroluminescent threads in blue, green, and yellow, that show compatibility with standard embroidery methods.

The researchers used the threads to stitch decorative designs onto a variety of consumer fabrics, without compromising their wearability or light-emitting capacity. The scientists illuminated specific messages or designs on the consumer products for the purpose of developing emergency alerts on helmet liners and as physical hazard signs.

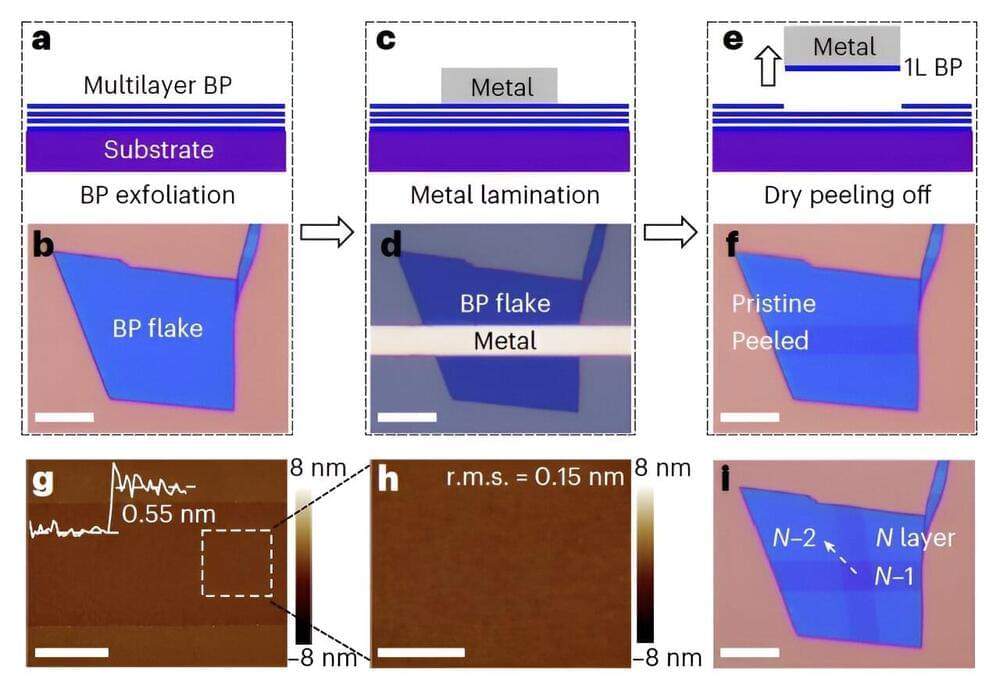

Two-dimensional (2D) semiconducting materials have proved to be very promising for the development of various electronic devices, including wearables and smaller electronics. These materials can have significant advantages over their bulky counterparts, for instance retaining their carrier mobility irrespective of their reduced thickness.

Despite their promise for creating thin electronics, 2D semiconductors have so far only rarely been used to create monolayer transistors, thinner versions of the crucial electronic components used to modulate and amplify electrical current inside most existing devices. Most proposed monolayer transistors based on 2D semiconductors were created using a few carefully selected materials known to have relatively stable lattice structures, such as graphene, tungsten diselenide or molybdenum disulfide (MoS2).

Researchers at Hunan University, the Chinese Academy of Sciences and Wuhan University recently set out to develop new monolayer transistors using alternative 2D semiconducting materials that have so far been primarily used to create multi-layer transistors, including black phosphorus (BP) and germanium arsenide (GeAs). Their work is published in the journal Nature Electronics.