US firm Dexterity unveils Mech, a super-humanoid robot using Physical AI to handle industrial tasks, starting with truck loading.

Category: transportation – Page 42

Upgraded anode moves seawater batteries step closer to primetime

As the world makes more use of renewable energy sources, new battery technology is needed to store electricity for the times when the sun isn’t shining, and the wind isn’t blowing.

“Current lithium batteries have reached their limitations in terms of energy storage capability, life cycle, and safety,” says Xiaolei Wang, a professor of chemical engineering at the University of Alberta in Edmonton. “They’re good for applications like electric vehicles and portable electronics, but they’re not suitable for large-scale grid-level energy storage.”

With the help of the Canadian Light Source at the University of Saskatchewan, Wang and his team are developing new technologies to help make grid-level aqueous batteries that can use seawater as an electrolyte. The study is published in the journal Advanced Materials.

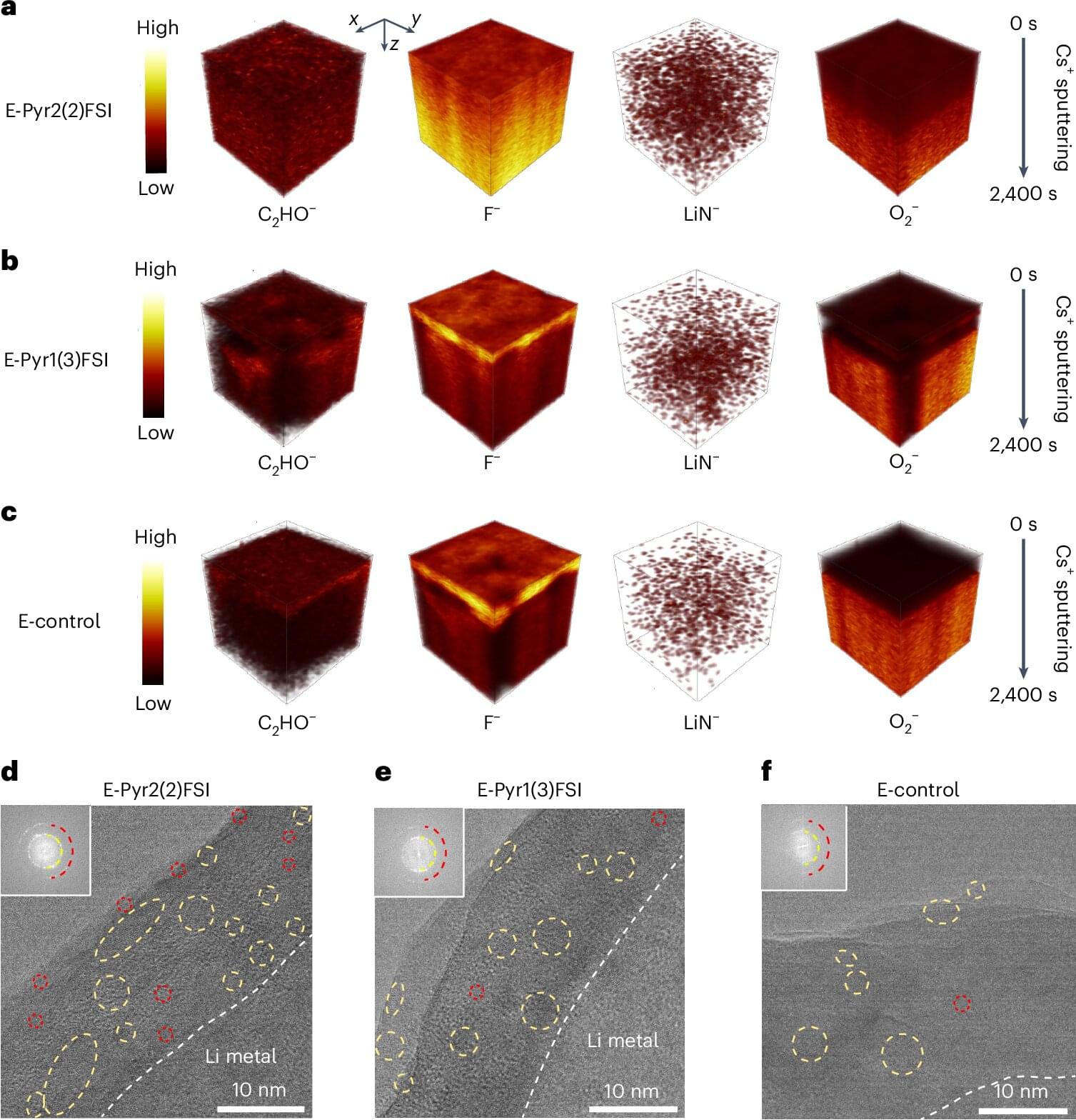

New electrolytes enable safe, stable and fast-charging lithium-metal batteries

In recent years, researchers have been trying to develop increasingly advanced battery technologies that can be charged faster and store more energy, while also remaining safe and stable over time. Lithium-metal batteries (LMBs), which contain a lithium-metal-based anode, have been found to be promising alternatives to lithium-ion batteries (LiBs), which are currently the most widely used rechargeable batteries.

A key advantage of LMBs is that they can store significantly more energy than LiBs, which could be advantageous for electric vehicles and other large or advanced electronics. Despite their potential, these batteries have so far proved to be less stable and safe than LiBs, while also charging relatively slowly; limitations that have so far prevented their widespread adoption.

A research team at the Korea Advanced Institute of Science and Technology (KAIST) and other institutes recently designed new electrolytes based on symmetric organic salts, which could help to boost the performance of LMBs. Their newly designed electrolytes, introduced in a paper in Nature Energy, were found to improve the stability and charging speed of LMBs, preventing the formation of dendrites (lithium deposits that cause a battery’s performance to decline over time).

Japan remembers victims of 1995 deadly Tokyo subway sarin attack

People in Japan are remembering the victims of the sarin gas attack on the Tokyo subway system on the 30th anniversary of the deadly incident on Thursday.

Members of the Aum Shinrikyo cult released highly toxic nerve gas in packed rush-hour subway cars on three lines in central Tokyo on March 20, 1995. Fourteen people died and about 6,300 others were injured.

At Kasumigaseki subway station, staff observed a moment of silence at around 8 a.m., almost the exact time of the attack.

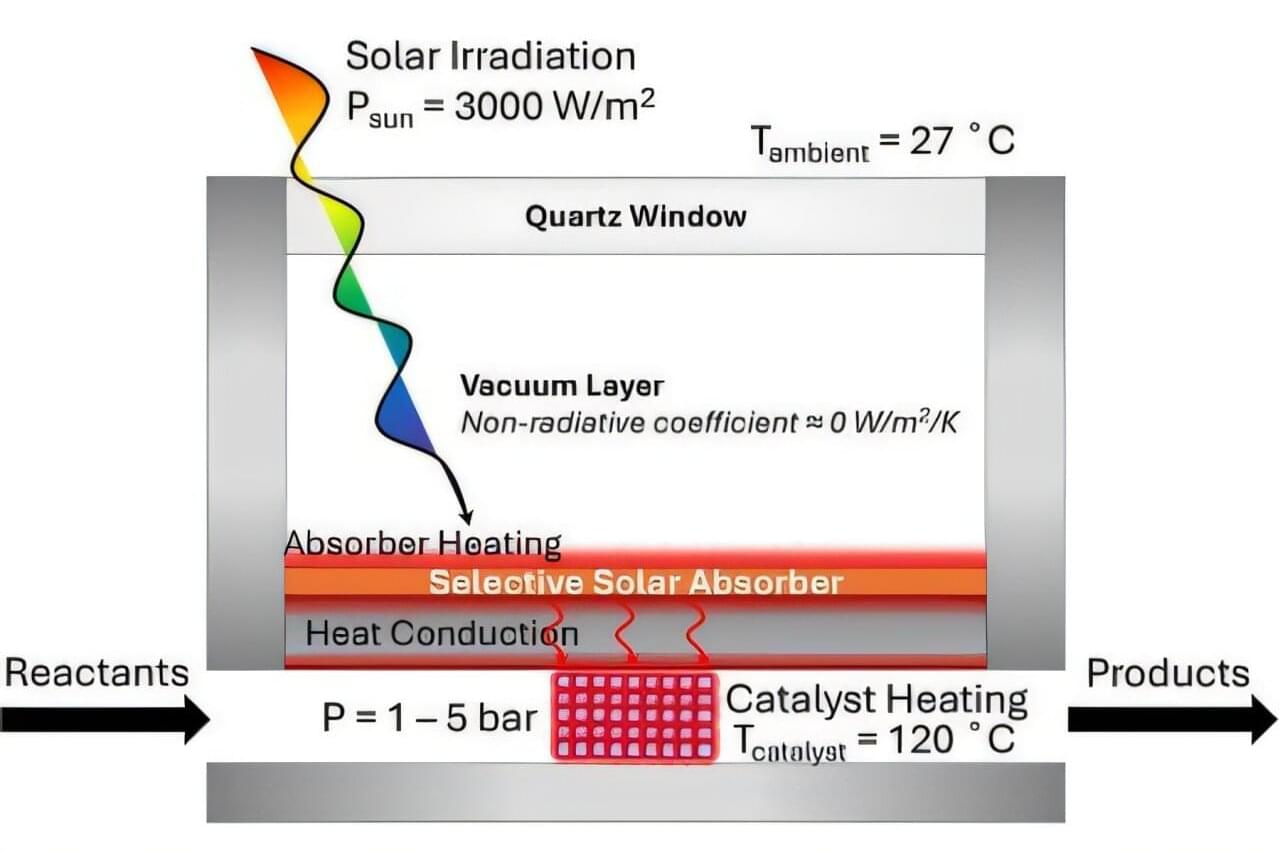

Solar-powered reactor shows potential for creating jet fuel with net-zero carbon emissions

Increasing energy demands and problems associated with burning fossil fuels have heightened interest in more sustainable energy sources, such as sunlight. But there are still areas where carbon-based fuel remains the standard, such as in the aviation industry. To address this need, scientists have been working to devise a way to use sunlight to generate solar-thermal heating that could then drive the chemical reactions that are needed to make jet fuel with net-zero carbon emissions.

Now, a team at Caltech that is part of a Department of Energy (DOE) Energy Innovation Hub known as the Liquid Sunlight Alliance, or LiSA, has developed such a solar-thermal heating system on a small scale and demonstrated that it can successfully drive an important reaction for jet fuel production.

Completely powered by solar energy, the so-called photothermocatalytic reactor incorporates a spectrally selective solar absorber to maximize the generation of solar-thermal heating. The modular design of the reactor takes advantage of current fabrication technologies and existing silicon solar panel production infrastructure.

AI Will Not Replace Humans, but “AI-Powered Humans” Are the Future

Artificial Intelligence (AI) has made significant strides in recent years, transforming various aspects of our lives. From self-driving cars to personalized recommendations on streaming platforms, AI has become an integral part of our daily existence. However, the fear that AI will replace humans entirely is unfounded. Instead, a more nuanced perspective emerges: AI will augment human capabilities, leading to the emergence of “AI-powered humans.”

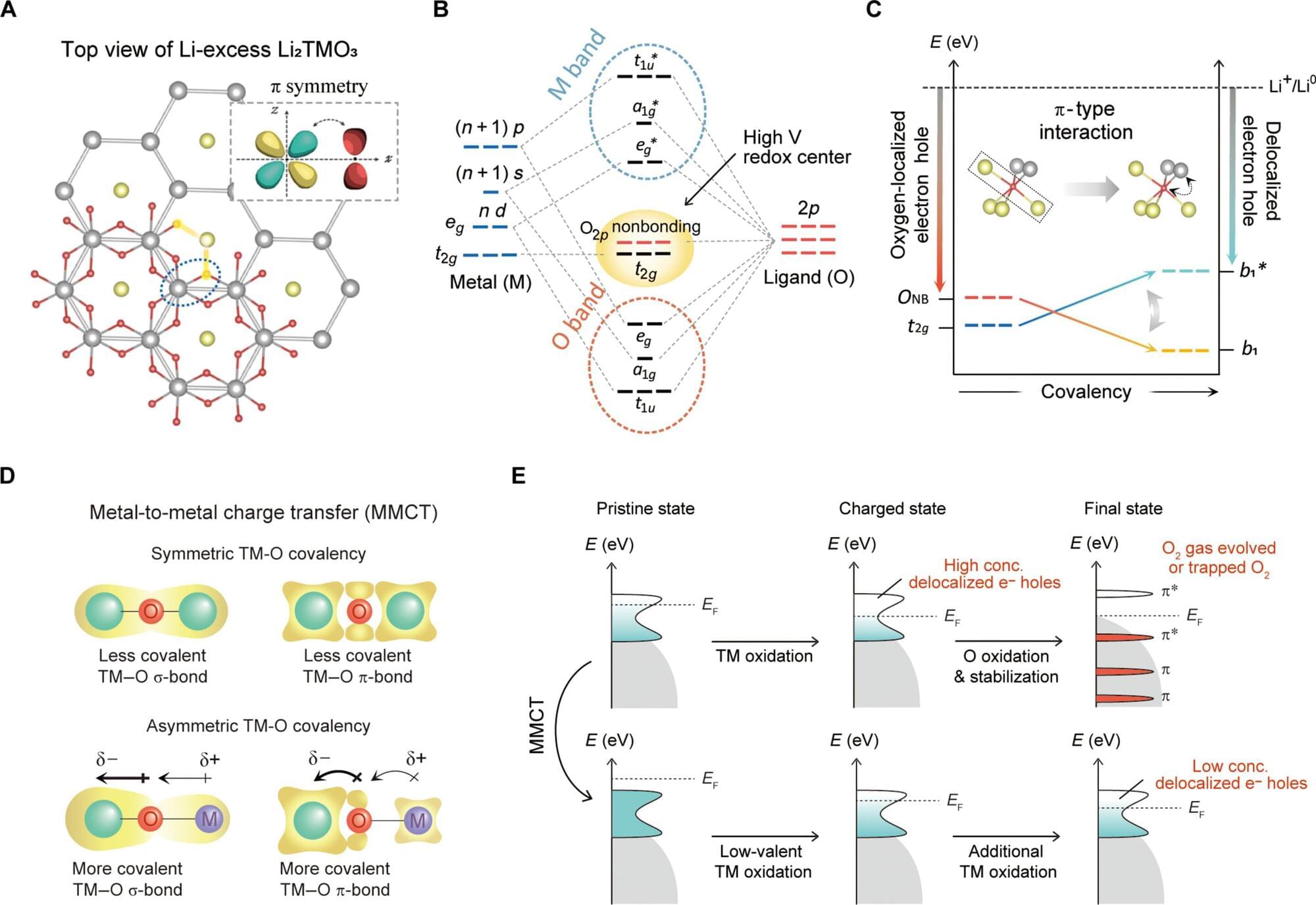

Electrode design could prevent explosions in next-gen batteries, allowing 1,000 km on a single charge

A research team at UNIST has identified the causes of oxygen generation in a novel cathode material called quasi-lithium and proposed a material design principle to address this issue.

Quasi-lithium materials theoretically enable batteries to store 30% to 70% more energy compared to existing technologies through high-voltage charging of over 4.5V. This advancement could allow electric vehicles to achieve a driving range of up to 1,000 km on a single charge. However, during the high-voltage charging process, oxygen trapped inside the material can oxidize and be released as gas, posing a significant explosion risk.

The research team, led by Professor Hyun-Wook Lee in the School of Energy and Chemical Engineering, discovered that oxygen oxidizes near 4.25V, causing partial structural deformation and gas release.

Can Elon Musk Make Tesla Stock More Valuable Than Nvidia With AI Products?

Structural adhesives play a crucial role in assembling automobiles, aircraft, and buildings. Among these, epoxy adhesives stand out for their exceptional mechanical strength and durability. However, traditional cured epoxy resins are often rigid and lack flexibility, resulting in low peel and impact strength.

Now, a groundbreaking advancement in structural adhesives has emerged from the laboratories of Nagoya University, promising to transform material bonding as we know it. This next-generation adhesive boasts an unprecedented impact strength – 22 times higher than conventional epoxy-based adhesives without rubbery additives.

New adhesive using elastomer makes lighter, more carbon-efficient vehicles possible.