Lovefrom, the creative firm founded by former Apple chief designer Jony Ive, played a role in the development of Rivian’s first electric bike, according to multiple sources who spoke to TechCrunch.

Questions to inspire discussion.

A: Tesla is testing FSD in the Arctic and awaiting regulatory approval for cities like Paris, Amsterdam, and Rome.

🇸🇪 Q: Why was FSD testing denied in Stockholm?

A: Stockholm denied FSD testing due to risks for infrastructure and pressure from ongoing innovation tasks.

🤖 Q: What improvements are expected in Tesla’s Grok AI?

A: Grok 3.5 will be trained on video data from Tesla cars and Optimus robots, enabling it to understand the world and perform tasks like dropping off passengers.

Researchers at the U.S. Department of Energy (DOE)’s Oak Ridge National Laboratory (ORNL) have developed an innovative new technique using carbon nanofibers to enhance binding in carbon fiber and other fiber-reinforced polymer composites—an advance likely to improve structural materials for automobiles, airplanes and other applications that require lightweight and strong materials.

The results, published in the journal Advanced Functional Materials, show promise for making products that are stronger and more affordable, opening new options for U.S. manufacturers to use carbon fiber in applications such as energy and national security.

“The challenge of improving adhesion between carbon fibers and the polymer matrix that surrounds them has been a concern in industry for some time, and a lot of research has gone into different approaches,” said Sumit Gupta, the ORNL researcher who led the project. “What we found is that a hybrid technique using carbon nanofibers to create chemical and mechanical bonding yields excellent results.”

Kali Linux 2025.2, the second release of the year, is now available for download with 13 new tools and an expanded car hacking toolkit.

March 25, 2025 (follow up)— Southwest Research Institute (SwRI) has launched the newest iteration of its industry-supported Hydrogen Internal Combustion Engine consortium, H2-ICE2.

In 2024, SwRI’s H2-ICE consortium completed construction of a Class 8, heavy-duty hydrogen-powered vehicle, following 18 months of targeted development. The demonstration vehicle achieves ultra-low nitrogen oxide and carbon dioxide emissions without sacrificing commercial viability. The consortium’s next iteration — “H2-ICE2” — will build on its prior success by enhancing and refining the vehicle’s overall performance and efficiency.

SwRI consortium will focus on enhancing H2-ICE-powered vehicle performance, efficiency.

OpenAI argues it needs access to ‘avoid forfeiting’ the lead in AI to China.

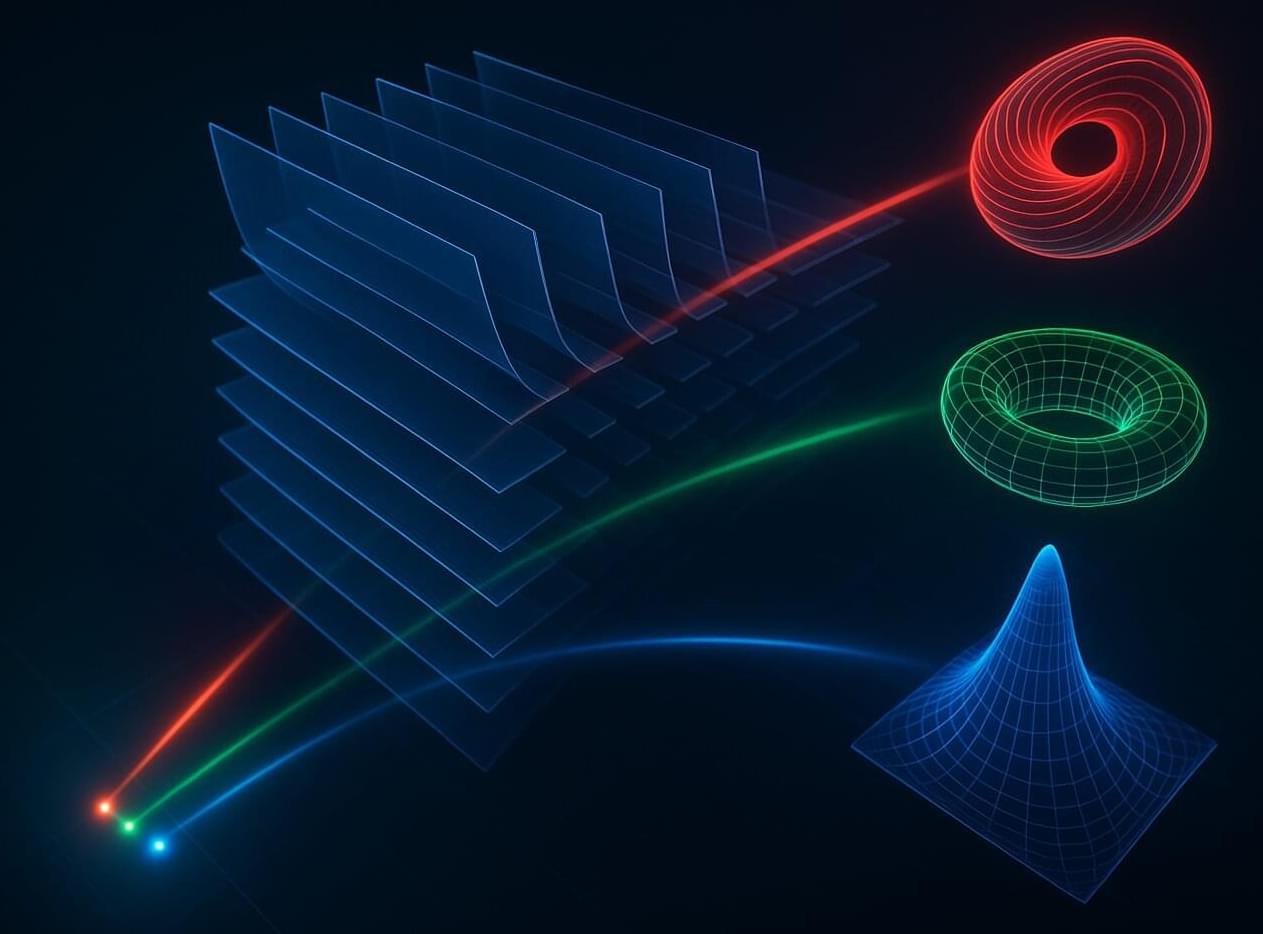

Engineers at the UCLA Samueli School of Engineering have introduced a universal framework for point spread function (PSF) engineering, enabling the synthesis of arbitrary, spatially varying 3D PSFs using diffractive optical processors. The research is published in the journal Light: Science & Applications.

This framework allows for advanced imaging capabilities—such as snapshot 3D multispectral imaging —without the need for spectral filters, axial scanning, or digital reconstruction.

PSF engineering plays a significant role in modern microscopy, spectroscopy and computational imaging. Conventional techniques typically employ phase masks at the pupil plane, which constrain the complexity and mathematical representation of the achievable PSF structures.