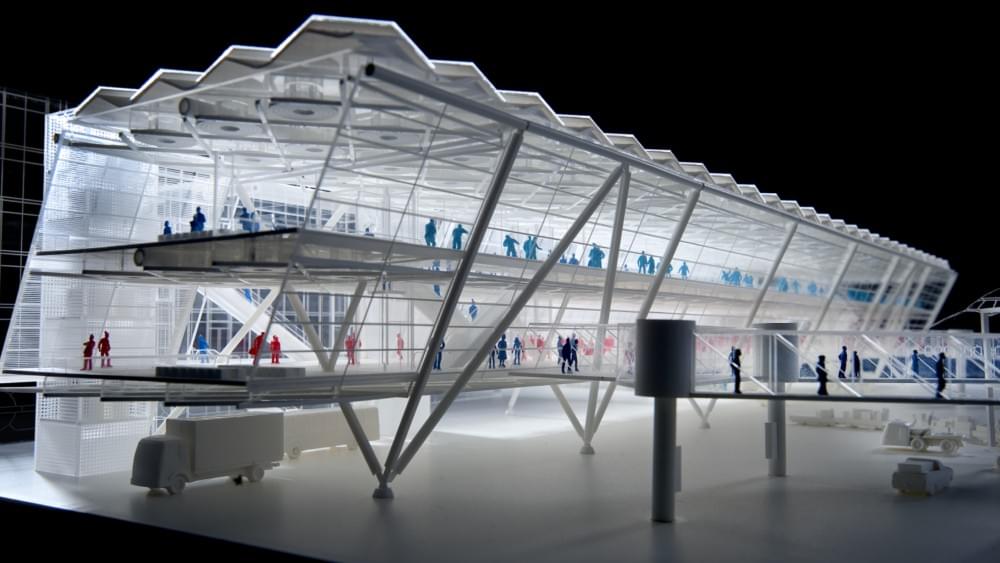

The G Train is an all-glass marvel designed for one owner to travel the world’s railways in ultimate luxury. Oh, and it’s totally doable.

The E-RA comes with a 60kWh battery meaning it likely won’t come with a world-beating range. However, Subaru hopes its new all-wheel-drive machine can excel on the race track. The car features GT-style, high-downforce composite bodywork with cutouts in the body to redirect air away from the wheel wells.

The Japanese automaker aims to set a record-breaking Nürburgring lap time of 6 minutes and 40 seconds by 2023. That would put it ahead of Tesla’s Model S Plaid, which completed the Nürburgring course in 7 minutes and 35 seconds. Before going to Nürburgring, Subaru will test the E-RA at Japanese racing circuits later this year.

Subaru also revealed the Solterra STI Concept on the show floor, a sportier version of its new Solterra all-electric SUV, which was revealed in November last year. Though Subaru didn’t reveal much in the way of specifications, the new Solterra concept features a roof spoiler, under spoilers, and “other special parts on the exterior,” the company says.

This is lecture 3 of course 6.S094: Deep Learning for Self-Driving Cars taught in Winter 2017. This lecture introduces computer vision, convolutional neural networks, and end-to-end learning of the driving task.

INFO:

Slides: http://bit.ly/2HdXYvf.

Website: https://deeplearning.mit.edu.

GitHub: https://github.com/lexfridman/mit-deep-learning.

Playlist: https://goo.gl/SLCb1y.

Links to individual lecture videos for the course:

Lecture 1: Introduction to Deep Learning and Self-Driving Cars.

Lecture 2: Deep Reinforcement Learning for Motion Planning.

https://youtu.be/QDzM8r3WgBw.

Lecture 3: Convolutional Neural Networks for End-to-End Learning of the Driving Task.

SEOUL — Using a high-performance artificial intelligence (AI) chip, South Korean researchers have established a system that can accelerate the process of learning data and yielding results. The system capable of performing five thousand trillion operations per second is ideal for autonomous vehicles and AI servers because its chipset is about the size of a coin.

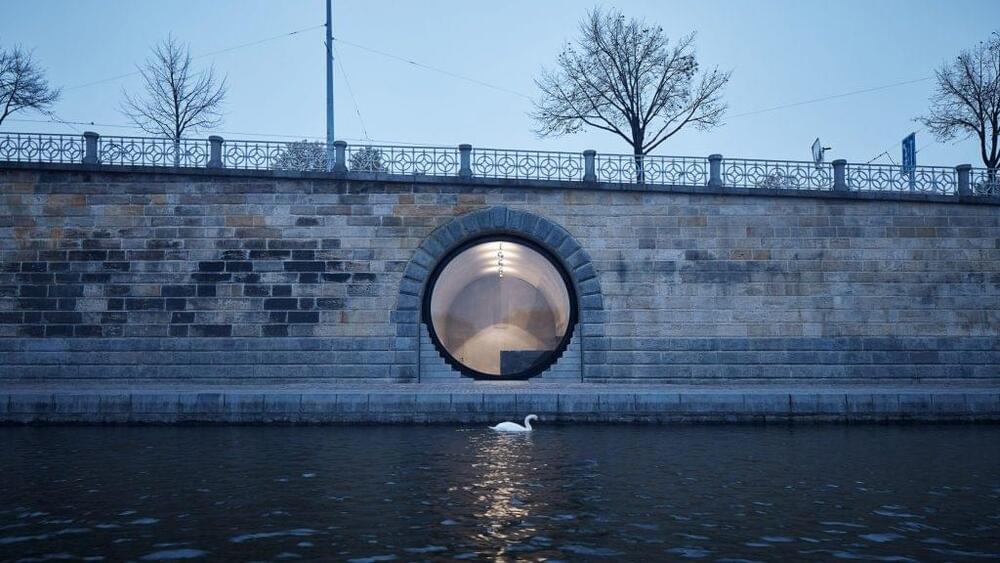

Architect Petr Janda has transformed a series of vaults on the banks of the Vltava River in Prague into versatile public spaces as part of a project aimed at revitalising the embankment.

The project to transform approximately four kilometres of the Czech capital’s riverbank was initiated in 2009, by which time the former quayside had been deserted for many years.

The embankment area was being used for car parking, with the vaults containing storage units. Janda’s studio Brainwork helped develop a proposal to create a waterfront promenade that reactivates three separate sections of the embankment and introduces new public functions.

LONDON, Jan 14 (Reuters) — BP says its fast electric vehicle chargers are on the cusp of becoming more profitable than filling up a petrol car.

The milestone will mark a significant moment for BP which wants to shift away from oil and expand operations in power markets and around electric vehicles (EV).

EV charging has for years been a loss-making business as a whole for BP and rivals as they invest heavily in its expansion. The division is not expected to turn profitable before 2025 but on a margin basis, BP’s fast battery charging points, which can replenish a battery within minutes, are nearing levels they see from filling up with petrol.

Next Fiat Panda aims for ‘most affordable EV’ title with customizable, clever crossover that will slot below 500e.

What’s the most affordable EV you can buy? If rumors out of Fiat are to be believed, the answer to that question will soon be “the new Fiat Panda” as Stellantis targets the bottom end of the booming electric car market.

Set to arrive as soon as this spring, the new Fiat Panda will be an EV-only offering from Stellantis’ “entry” Italian brand, and is expected to slot in below the ell-electric Fiat 500e, price-wise, in the company’s lineup. Its main objective, as the brand’s President, Oliver Francois, told AutoExpress UK, is to “awaken the sleeping giant” he believes Fiat to be. “That’s exactly my point of view,” he says, when discussing new models. “We have not even started awakening the giant.”

As a product, the upcoming Fiat Panda is believed to be heavily based on Fiat’s 2019 concept, the award-winning Fiat Centoventi. At the time, the company said it would reduce the car’s build costs by adopting a spartan design with a limited color palette that was at once “minimalist and fully customizable.”

It takes off vertically then moves horizontally.

Zeva Aero, a Tacoma-based company looking to make vertical take-off and landing (VTOL) vehicles for a single pilot, reached a major milestone as its full-scale aircraft completed its maiden untethered flight, the company said in its press release.

We have covered many electric VTOL (eVTOL) concepts in the past and covered their progress as well. While most are aimed to become air taxis, capable of moving people from point A to point B within or even between cities, Zeva’s Zero wants to offer this service on a highly personalized basis, giving its users the freedom from aircraft pilots to chauffeur them around. A typical Zeva Zero user could lift from practically any parking lot in the city, negating the need for dedicated vertiports as well.

Full Story:

The VTOL might look a little odd at first glance. But the oddity of the design gives it unmatchable speeds among VTOLs.