Held aloft by helium and powered electricity, they will seat 100 passengers, and typically fly 300–400 kilometers (186−249 miles).

Air Nostrum, a Spanish airline, has ordered 10 Airlander 10 aircraft to make regional journeys around Spain.

The legendary Skunk Works had a hand in developing Tom Cruise’s fastest plane yet.

In Top Gun: Maverick, Captain Pete “Maverick” Mitchell takes his need for speed to a new realm: the hypersonic realm, that is. Thirty-six years after the first film debuted, Mitchell is a test pilot flying the SR-72 “Darkstar” airplane. Although fictional, the SR-72 has a real-world pedigree, with design help for the aircraft and models coming from the same group that is designing the real SR-72: the world-famous Skunk Works, Lockheed Martin’s Advanced Development Programs.

According to Lockheed Martin, the production team behind Top Gun: Maverick contacted the company’s Skunk Works division to assist with the SR-72 concept. The Skunk Works, a name drawn from the cartoon Li’l Abner, is the division of Lockheed Martin that works on classified aircraft programs.

Charging technology provider EV Safe Charge has unveiled ZiGGY – a mobile robot that can charge an EV wherever it’s parked. Through its ability to recharge itself via different energy sources and its summoning feature, ZiGGY can alleviate the need to install specific parking stalls for EV charging, as any spot can now become a spot to recharge.

EV Safe Charge currently provides end-to-end charging solutions, particularly as it pertains to mobile charging. The company created a mobile rental charging solution for the launch of Jaguar’s I-PACE EV and works with several other OEMs like Audi, Mercedes-Benz, Nissan, Porsche, and Stellantis.

Previously, EV Safe Charge has helped find its clients ideal charging solutions based on their needs, recommending charging technology from a multitude of partners including ABB, Enel X, evconnect, and Bosch.

Check it out and post some of the stuff from it. My favorite because of fuel prices was this:

Many innovations in the mobility sector will be on the agenda, among them Japanese electric inflatable vehicles transportable in a backpack and operational in just a few seconds from Poimo, which will be seen for the first time outside Japan.

You will find many more innovations to investigate and post. Just google the companies listed in the link and their innovations.

VivaTech is the world’s rendezvous for startups and leaders to celebrate innovation. It’s a gathering of the world’s brightest minds, talents, and products.

Also from 0 to 80% in 5.2 minutes. When it comes to electric vehicles, the main concern is the range anxiety related to mileage per charge and charging time.

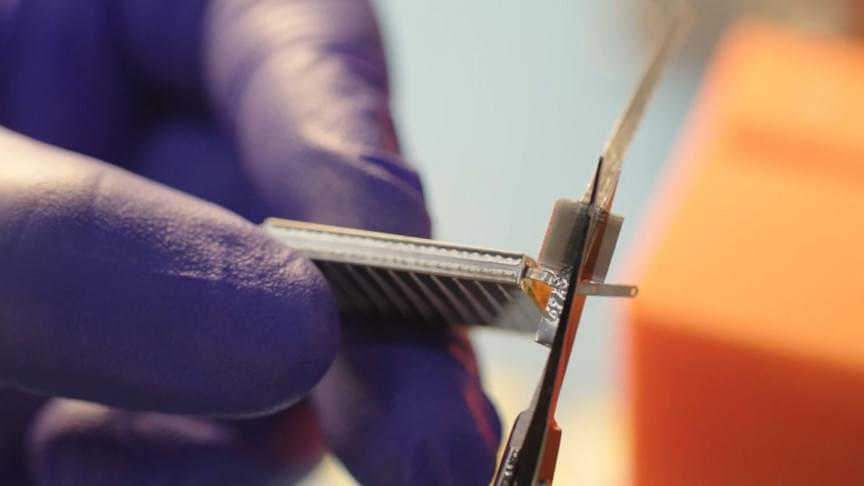

Enovix’s 3D Silicon Lithium-ion battery. Enovix

When it comes to electric vehicles, the main concern is the range anxiet y related to mileage per charge and charging time.

Now a company from the U.S. seems to have a solution for charging time.

Following the launch of the limited-edition Pioneer Series electric micro car last month, Micro Mobility Systems AG has now opened up an online configuration tool to Microlino reservation holders and confirmed pricing.

The road to production of the Microlino electric bubble car began with a very Isetta-looking all-electric design at the 2016 Geneva Motor Show. This version didn’t reach production, but underwent a retro-modern redesign in 2020 in collaboration with thousands of reservation holders.

Three Microlino 2.0 series editions were announced last year, followed most recently by the launch of the first 999 vehicles to go into production at the company’s dedication manufacturing facility in Turin, Italy.

BEIJING — As Chinese companies race for a slice of the world’s largest car market, they’re betting heavily on assisted driving technology.

China sold nearly 21.5 million passenger cars last year. That’s roughly the equivalent of sales in the United States, Europe and Japan combined, according to industry data accessed through the Wind database.

Electric cars have grabbed a growing share of that Chinese market. Tesla, start-ups like Nio and traditional automakers have jumped in. After initially competing on battery driving range and in-car online entertainment, companies increasingly emphasize assisted driving capability.

Kaizen Clean Energy (KCE) and ZincFive have come together to develop an integrated distributed energy solution for EV charging, hydrogen fueling and backup power. The new solution is said to provide the lowest delivered cost for hydrogen fueling, as well as up to 2,300 kg/day of hydrogen production, which is equivalent to 38 MWh of usable energy, in a 40-foot, movable containerized solution. It can be islanded or grid-connected, with no risk of battery thermal runaway and a small volume of hydrogen stored on site. The system integrates KCE’s hydrogen generator, ZincFive’s immediate power nickel-zinc batteries, and fuel cells from Power Cell to offer customers modular, scalable economic fueling as a service. Robert Meaney, co-founder of KCE, told pv magazine that the energy input comes from methanol. He said the system is essentially the clean version of a diesel generator. It uses the ZincFive battery for immediate demand response as the methanol-to-hydrogen system ramps up to full production over the first 15 minutes. After entering full production mode, the batteries shut off and the reformer takes over the full power demand. The system is charger agnostic and can support multiple DC fast chargers at once. KCE has started accepting pre-orders and plans to deploy a 20-foot, 150 kW solution with pilot customers in the fourth quarter of 2022.

Lightyear has launched the final design of its long-range, production-ready solar car. The model, which has been renamed “Lightyear 0,” has a Worldwide Harmonized Light Vehicle Test Procedure (WLTP) range of 625 kilometers and consumption of 10.5 kWh per 100 kilometers. However, the Dutch startup claims that a theoretical range of 695 kilometers could be achieved, with a battery pack capacity of 60 kWh. “The optimized solar roof and holistic design mean that the car can drive for weeks, even months, without charging,” the company said. Lightyear is already readying its second solar electric car, which will be available by late 2024 or early 2025.

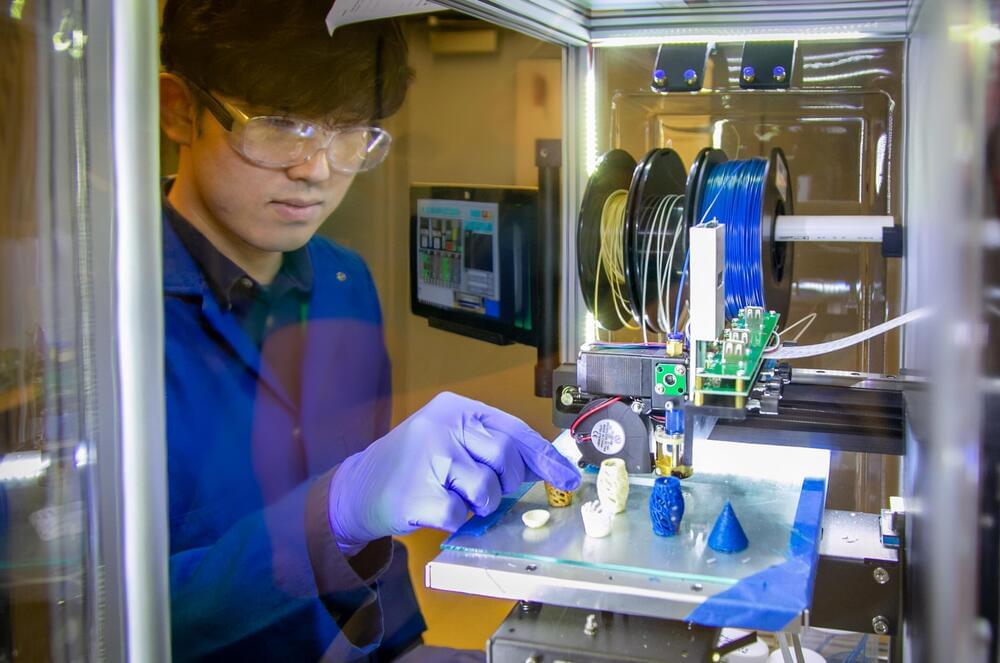

Researchers at the Department of Energy’s Oak Ridge National Laboratory have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing. The readily adoptable, scalable method introduces a closed-loop strategy that could globally reduce plastic waste and cut carbon emissions tied to plastic production.

Results published in Science Advances detail the simple process for upcycling a commodity plastic into a more robust material compatible with industry 3D-printing methods.

The team upgraded acrylonitrile butadiene styrene, or ABS, a popular thermoplastic found in everyday objects ranging from auto parts to tennis balls to LEGO blocks. ABS is a popular feedstock for fused filament fabrication, or FFF, one of the most widely used 3D-printing methods. The upcycled version boasts enhanced strength, toughness and chemical resistance, making it attractive for FFF to meet new and higher performance applications not achievable with standard ABS.