Facial recognition is a technology that can identify or verify a person’s identity based on their face. It can be used for various purposes, such as unlocking smartphones, verifying identities at airports, or finding missing persons. However, facial recognition also seriously threatens personal privacy, as it can be used to track, monitor, or profile people without their consent or knowledge. For example, some governments or companies may use facial recognition to spy on citizens, customers, or competitors or to collect and sell their data.

How can we prevent facial recognition from invading our privacy?

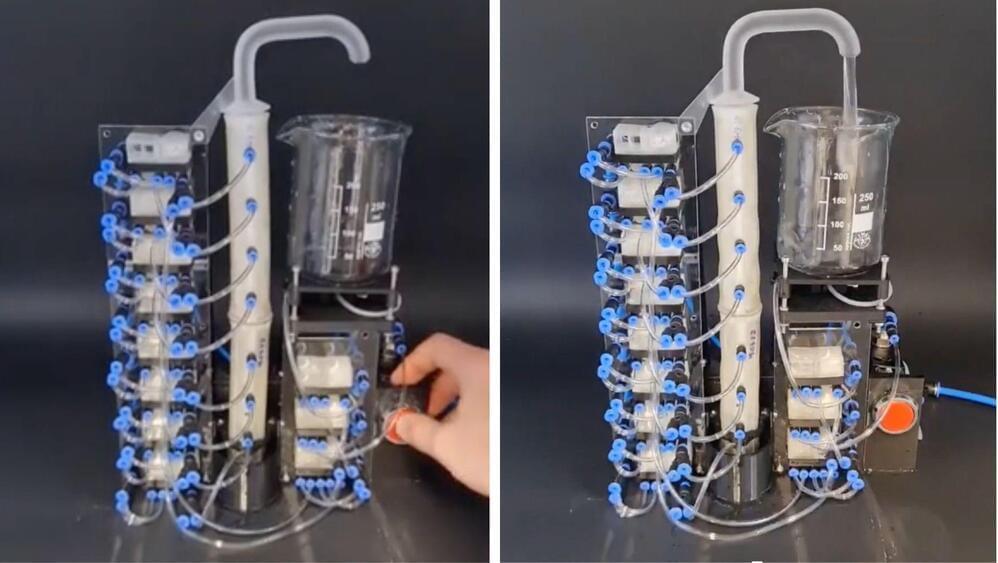

To protect our facial privacy, some researchers have proposed different methods to prevent facial recognition from working. These methods, collectively called anti-facial recognition (AFR), aim to hide, distort, or replace the faces in images or videos. For instance, some AFR methods use masks, makeup, glasses, or hats to cover or alter facial features. Other AFR methods use software to blur, pixelate, or swap the faces in digital media.