In the simplest terms, nearly every modern car on the planet uses disk brakes: a rotor attached to a hub with a caliper with brake pads fixed to the control arm at each wheel. The driver presses the brake pedal and hydraulic fluid is pushed down the brake lines into the caliper, expanding the pistons and pushing the brake pads against the rotor, slowing down the rotation of the rotor connected to the hub, thus slowing down the wheel.

There are other systems, like drum brakes, air brakes, band brakes, the Flintstones method, et cetera, that have also been around since the dawn of the automotive industry. The concept almost always remains the same: using friction to slow down. And so it doesn’t go unsaid, yes, there are compression brake systems as well, but that’s entirely different.

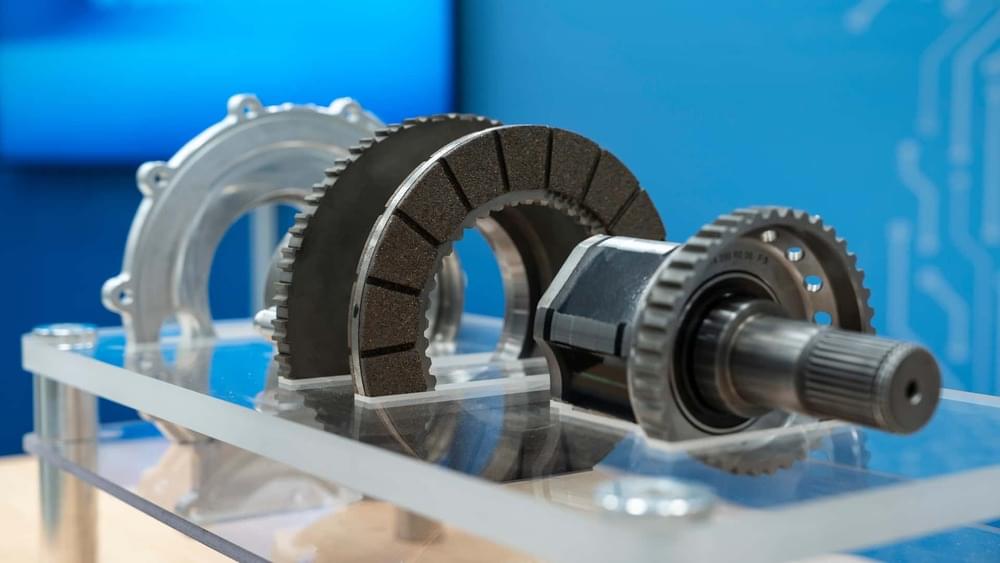

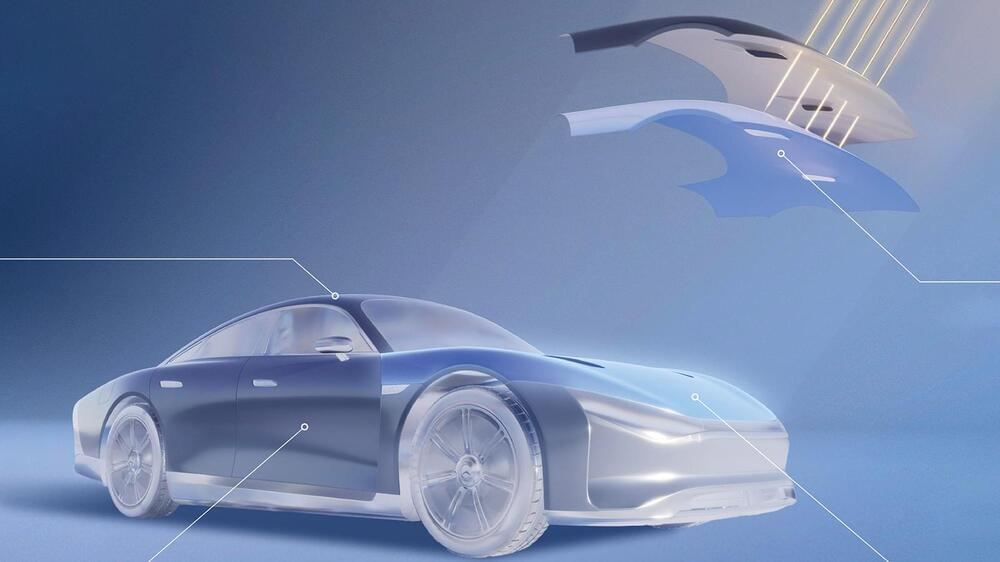

Mercedes-Benz has put a new spin on an age-old concept with what it calls “in-drive brakes” for electric vehicles. The system being developed at the company’s research and development department in Sindelfingen, Germany, integrates the brakes right into the drivetrain, in an arrangement that works very much like a transmission brake. It resembles clutch plates – but with a unique twist.