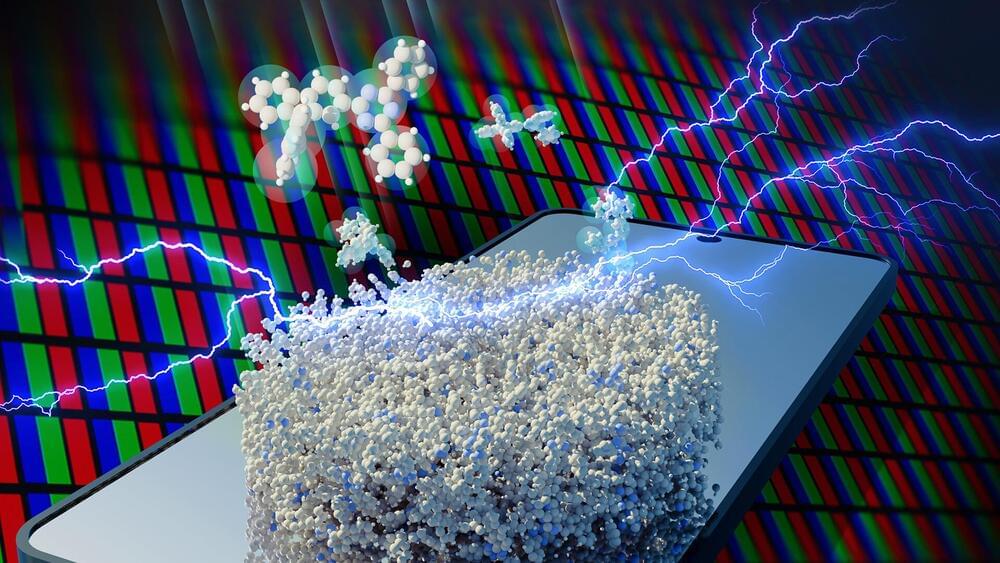

A new solar cell process using Sn(II)-perovskite oxide material offers a promising pathway for green hydrogen production through water splitting, advancing sustainable energy technologies.

Experts in nanoscale chemistry have made significant progress toward sustainable and efficient hydrogen production from water using solar power.

An international collaborative study led by Flinders University, involving researchers from South Australia, the US, and Germany, has uncovered a novel solar cell process that could play a key role in future technologies for photocatalytic water splitting—a critical step in green hydrogen production.