Just need 400 billion and 1.2% of the land area.

Desertec continues in a smaller form; they’re still building power plants in Morocco to supply the local energy needs of that country. Perhaps a ground-up approach, where MENA countries increase their own solar production in the desert before becoming net exporters, will provide the solution. This project is not the first wildly ambitious scheme to provide for the world’s energy needs that has stalled; historians remember Atlantropa, a scheme to dam the Strait of Gibraltar and use it for hydroelectric power that had some interest in the 1920s.

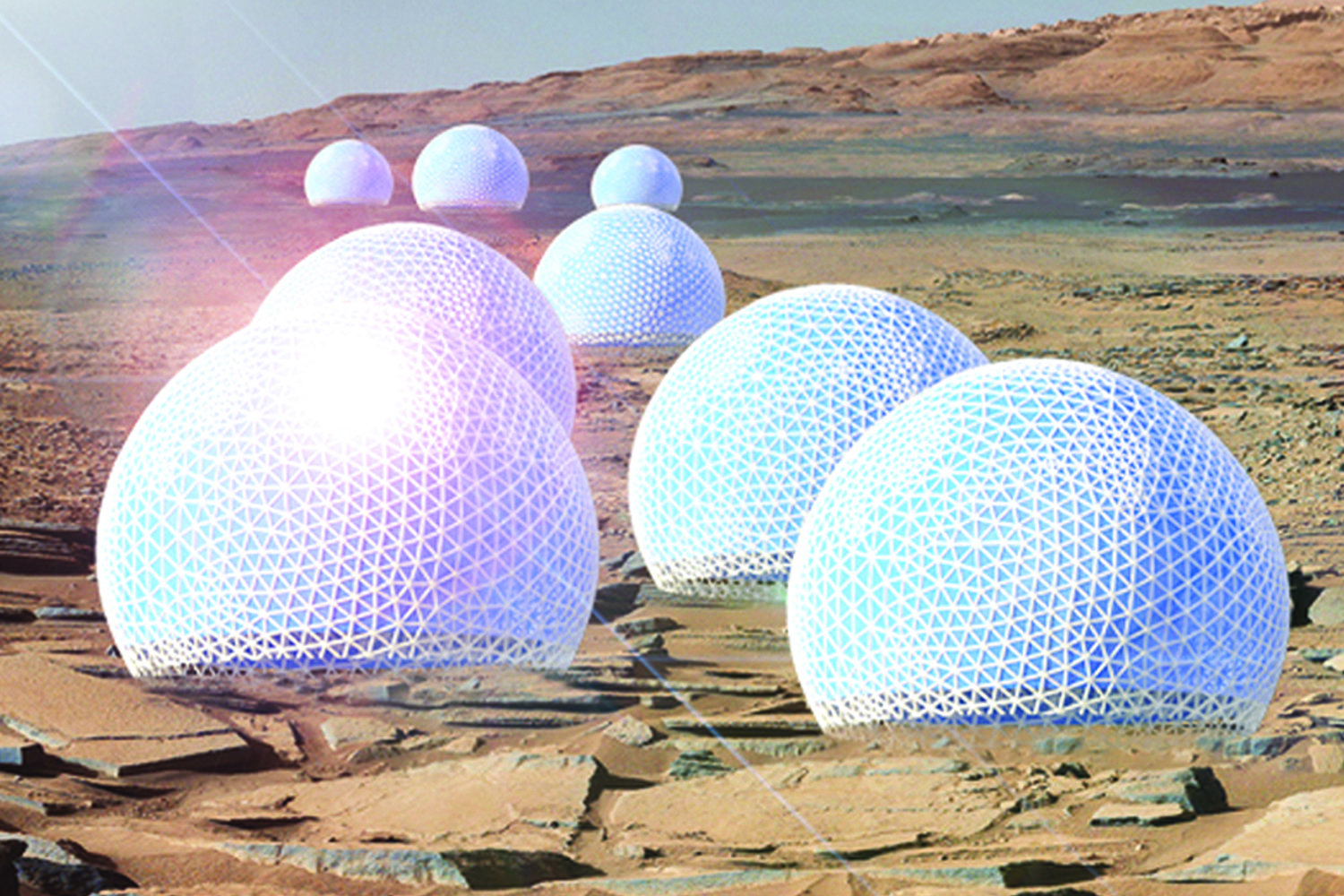

Yet the prospect remains tantalizing. Surely, when only a tiny fraction of the Earth’s surface need be devoted to energy production to provide us with more power than we could ever dream of consuming, we won’t wreck the planet by getting that energy through dirty and dangerous means. To starry-eyed idealists, it must seem equivalent to being on a raft in a lake full of drinking water—and choosing instead to swig from a bottle of seawater in your backpack. Solar power in the world’s deserts is one of the few feasible, renewable ways of providing energy on the scale we currently demand as humans. Someday, we will make better use of the abundant energy from the sun. We’ll have to.

Image Credit: https://www.shutterstock.com/image-illustration/egypt-surrou...-444689929”">Harvepino / https://www.shutterstock.com/”">Shutterstock.com