Japanese are increasingly turning to “social robots”, John Deere’s latest self-driving tractor will enable autonomous farming, a new South Australian craft beer has been designed entirely by AI.

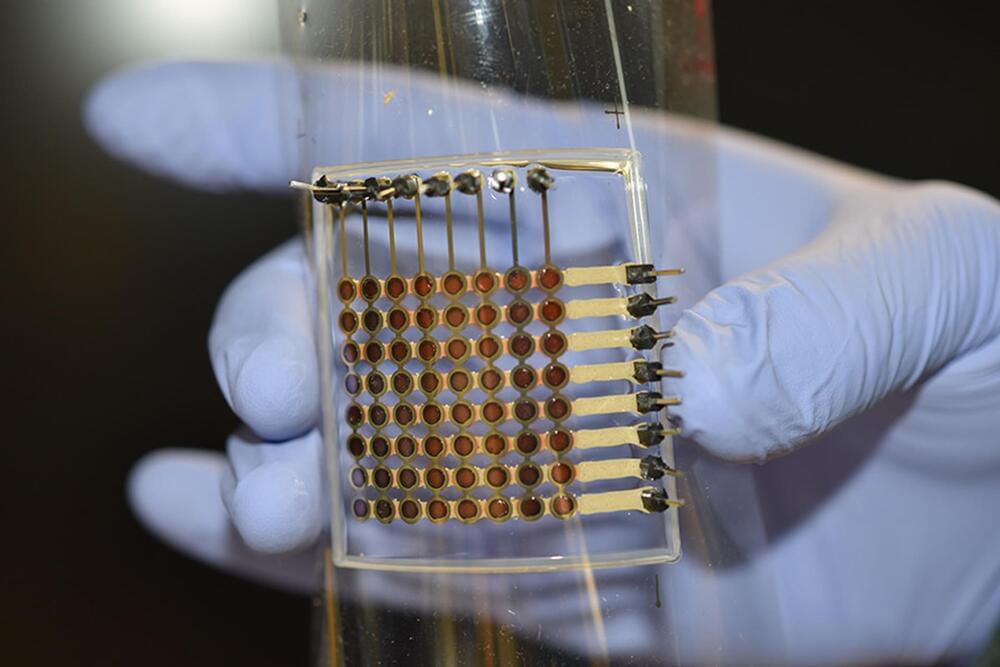

The researchers used extrusion printing to manufacture the electrodes, interconnects, encapsulation, and insulation. Active layers were then spray painted on at room temperature. All in all, six layers were 3D printed to build a flexible and fully functioning display.

“OLED displays are usually produced in big, expensive, ultra-clean fabrication facilities,” said Michael McAlpine, senior author of the team’s new study. “We wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.”

An editorial writer and columnist for the Washington Post wrote a screed attacking electric cars this week. His heavily slanted piece was filled with misinformation. Here’s the truth about driving an electric car in winter.

Last week, hundreds of motorists on I-95 in Virginia were stuck for hours when a blizzard closed the highway south of Washington, DC. Highway crews couldn’t spread ice-melting chemicals before the storm arrived because the rain that preceded it would have washed them away. But when temperatures dropped, the rain quickly turned to ice. Then the snow came and made the ice treacherously slippery. Tractor trailers trying to get off the highway lost control, blocking many exit ramps. Senator Tim Kaine was trapped in the tangled mess of stalled cars for 27 hours.

Afterwards, Charles Lane, an editorial writer and columnist for the Washington Post, wrote a blistering opinion piece entitled, “Imagine Virginia’s Icy Traffic Catastrophe — But With Only Electric Vehicles.” In it, he wails about the Tesla driver who banged on the door of a tractor trailer, begging for help because he was afraid his family might freeze to death if his battery ran out of power. “If everyone had been driving electric vehicles, this mess could well have been worse,” Lane writes.

He goes on to say even Tesla warns on its website the cold temperatures can reduce range. Charging a cold battery takes longer, and besides, he says, there aren’t that many charging stations anyway. And what happens if the power goes out? What then? Lane, a graduate of Yale law school, apparently lacks the mental capacity to realize that when the power goes out, gas pumps stop working as well.

You might not have to send your devices in (or buy replacement parts) if the display breaks — you could just make new screens yourself. University of Minnesota Twin Cities researchers have developed what they say is the first fully 3D-printed flexible OLED display. In theory, you wouldn’t have to depend on panels made at large, distant factories to build or repair your gadgets.

The new approach combines two methods of 3D printing to print the six layers needed for a functional display. The team used extrusion printing to make the electrodes, encapsulation, insulation and interconnects, while active layers were spray-painted at room temperature. Past attempts by various teams either had issues with light uniformity (consistency across the whole panel) or relied on techniques beyond 3D printing to put some components in place, such as spin-coating or thermal evaporation.

The prototype was just 1.5 inches wide and used just 64 pixels. Any practical uses would require much higher resolutions (a 1080p display requires over 2 million pixels), and the scientists also want to improve brightness. It might also take a while to adapt the technology for home use. The university used a custom 3D printer that costs as much as a Tesla Model S — it might take a while for the method to be viable on off-the-shelf printers, even including high-end models like FormLabs’ $4,850 3B+.

China’s technology giant Baidu is stepping up its efforts to expand in the autonomous vehicle segment with the commercial launch of a car model with Level-2 self-driving technology next year.

Last week the company’s CEO Robin Li confirmed that Jidu Auto, Baidu’s joint venture with local automaker Zhejiang Geely Holding Group, plans to begin mass production of its first electric vehicle (EV) with Level-2 autonomous driving technologies in 2023. The vehicle’s self-driving system is powered by Nvidia chips and is scheduled to be unveiled at the Beijing Auto Show in April of this year.

Baidu, known widely as an internet search engine and artificial intelligence company, is targeting the autonomous vehicle segment as a key growth industry and is in the process of rolling out autonomous taxi services across China.

HYBRIT and H2 Green Steel have launched projects in Sweden with a target to manufacture 10 million tonnes (mt) of fossil fuel-free crude (green) steel per year by 2030. Success, of course, depends on the numbers adding up, or rather, the numbers going down.

To make green steel, you need green hydrogen; to make green hydrogen, you need cheap renewable energy. HYBRIT and H2 Green Steel believe this will come from wind power at a LCOE of $30 per megawatt-hour. With the trajectory of costs for renewable energy going ever downward, it is likely they will be able to achieve this.

Add to the mix the increasing costs of carbon and the pressure to decarbonize, and you have a winner. It is expected that a carbon credits will be available to green steel producers of around $85 per ton.

About a decade ago, MIT researchers discovered a technique that speeds physics modeling by 1000X. They spun this out into a new company, called Akselos, which has been helping enterprises to weave the tech into various kinds of digital twins used to improve shipping, refining, and wind power generation.

A digital twin is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning, and reasoning to help decision-making. Connected sensors on the physical asset collect data that can be mapped onto the virtual model.

The specific innovation improves the performance of finite element analysis (FEA) algorithms which underpin most types of physics simulations. Akselos experience over the last decade can help executives explore the implications of the million-fold improvements in physics simulation that Nvidia is now demonstrating thanks to improvement in hardware, scalability, and new algorithms.

iSun has won a massive solar canopy order. But who’s buying?

There are not many things I love more than a solar power canopy that charges an EV charging station. It’s all right there — transferring sunlight into electricity and then using that electricity to power a modern electric car; driving on sunshine.

So, it’s quite exciting to see that iSun (NASDAQ: ISUN) has been awarded a contract to provide 1,780 solar power canopies for EV charging stations. The problem is: we don’t have much more detail than that. We don’t know where these charging stations are and don’t know who is procuring the solar canopies.