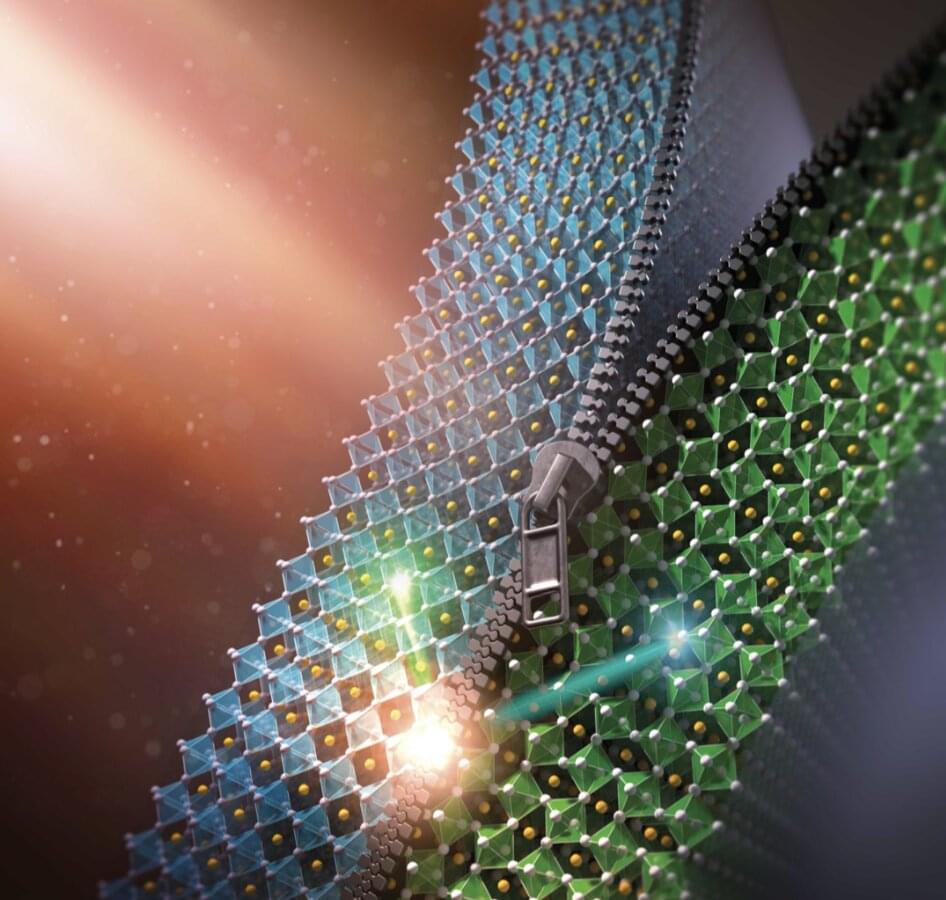

Over the past few decades, engineers and material scientists have created increasingly advanced and efficient solar technologies. Some of these technologies are based on photovoltaics with a so-called heterojunction structure, which entails the integration of two materials with distinct optoelectronic properties.

Researchers at Technische Universität Dresden have recently realized a different type of solar cells, referred to as phase heterojunction (PHJ) solar cells. These cells, introduced in a paper published in Nature Energy, were fabricated using two polymorphs (i.e., structural forms) of the same material, the perovskite CsPbI3, instead of two entirely different semiconductors.

“The realization of a PHJ requires the ability to fabricate two different phases of the same perovskite composition on top of each other,” Yana Vaynzof, lead author of the paper, told TechXplore. “While the fabrication of CsPbI3 perovskite by solution-processing is well established in the literature, we needed to develop a method to deposit a perovskite without dissolving the underlying layer, so we decided to use thermal evaporation for this purpose.”