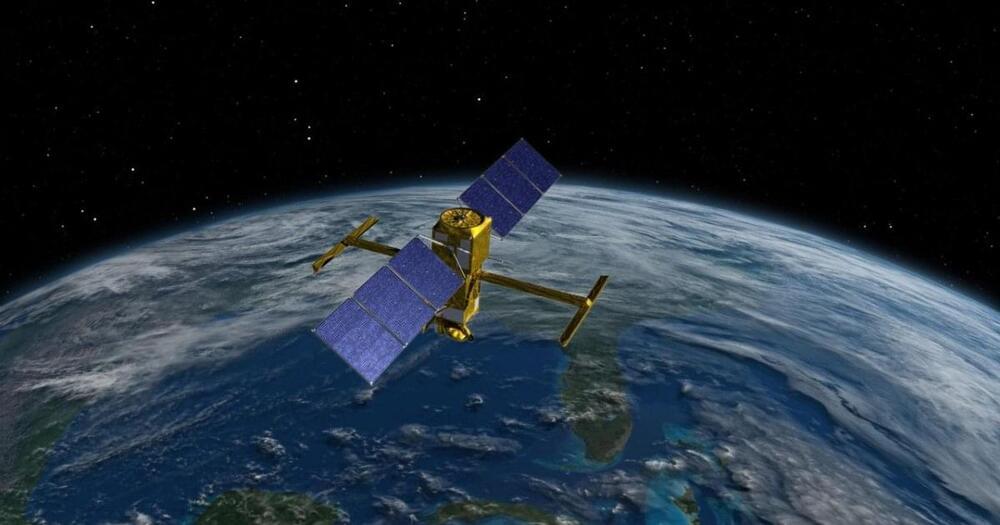

A new demo from Caltech will test the viability of unlimited solar power beamed back to Earth from orbit.

A new demo from Caltech is set to launch in January 2023, and it could shake up the way we collect and harvest solar power in the future.

Caltech’s Space Solar Power Project (SSPP) is getting ready to put its first Space Solar Power Demonstrator into space to test new technologies that could make the dream of space-based solar power harvesting — which could yield considerably more energy than ground-based solar arrays — closer to reality.