Heat has always been something we thought we understood. From baking bread to running engines, the idea seemed simple: heat spreads out smoothly, like water soaking through a sponge. That simple picture, written down by Joseph Fourier 200 years ago, became the foundation of modern science and engineering.

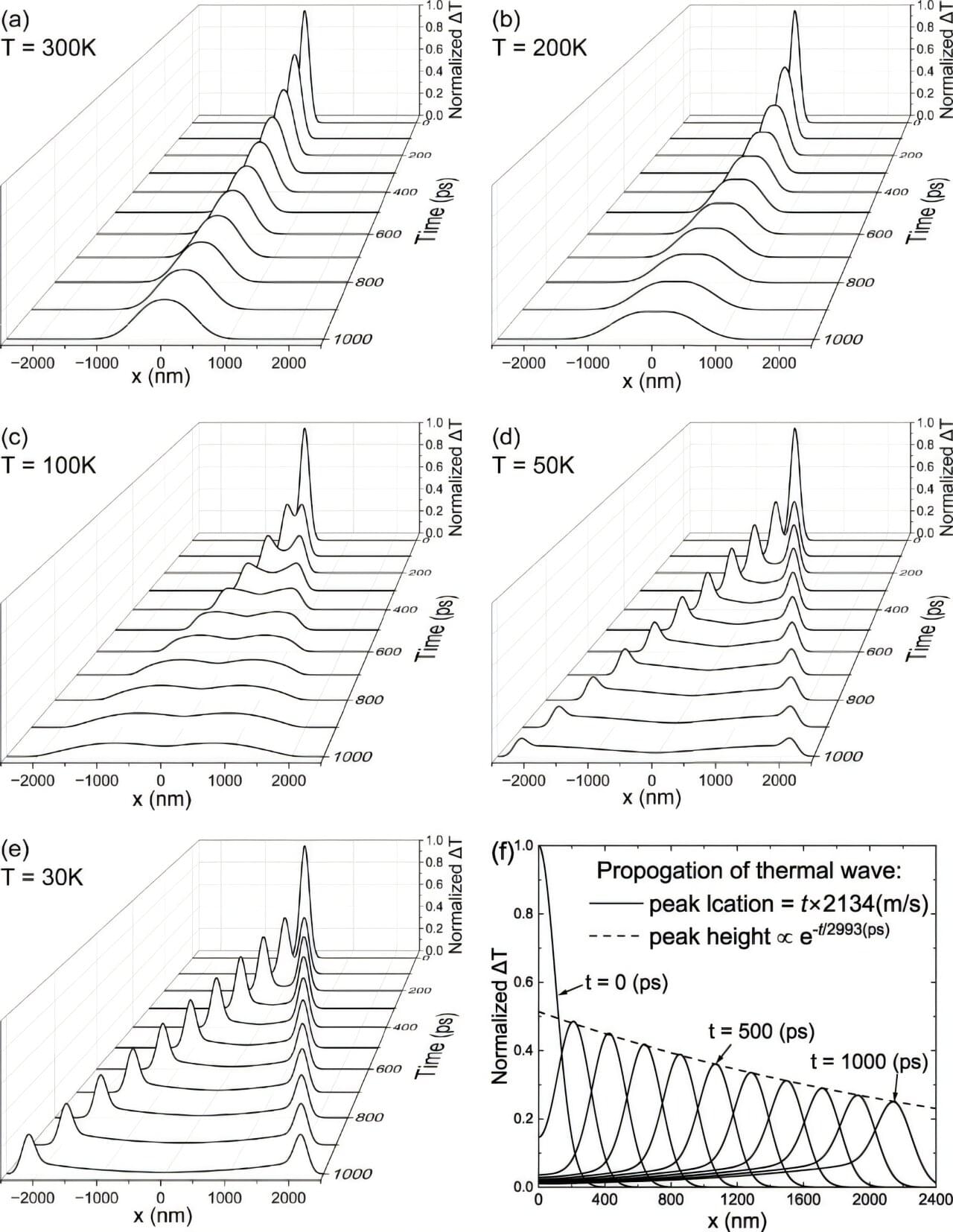

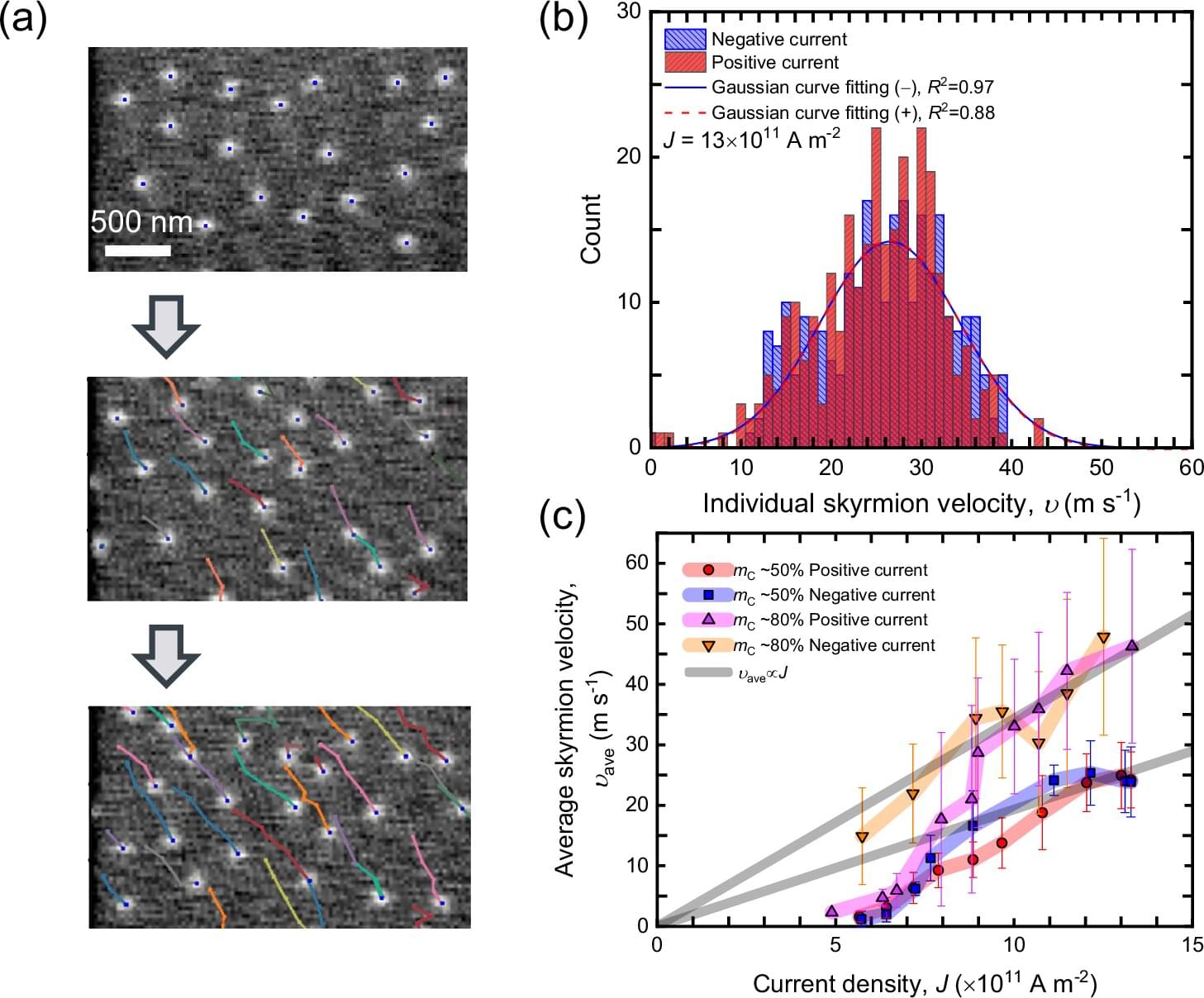

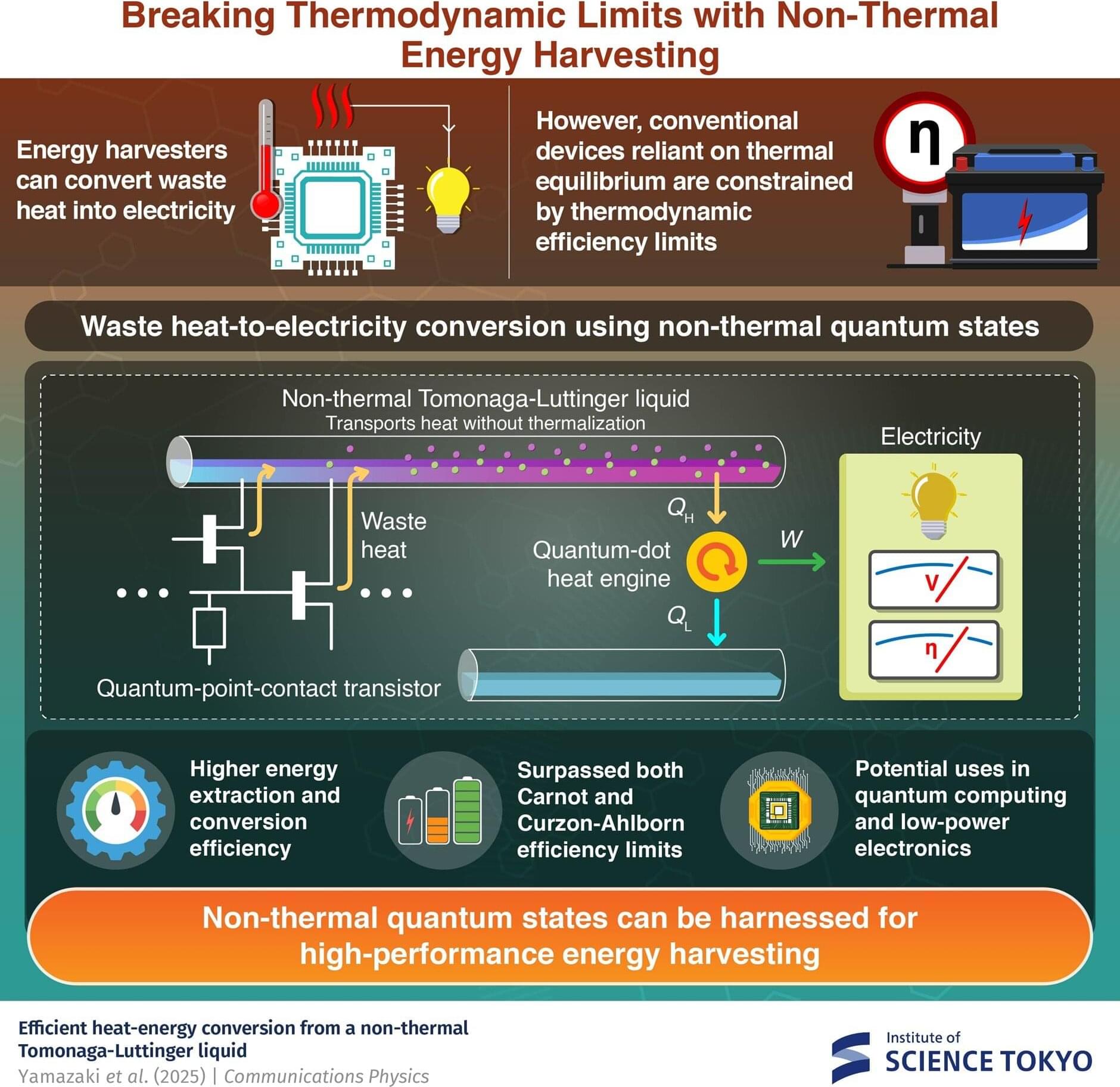

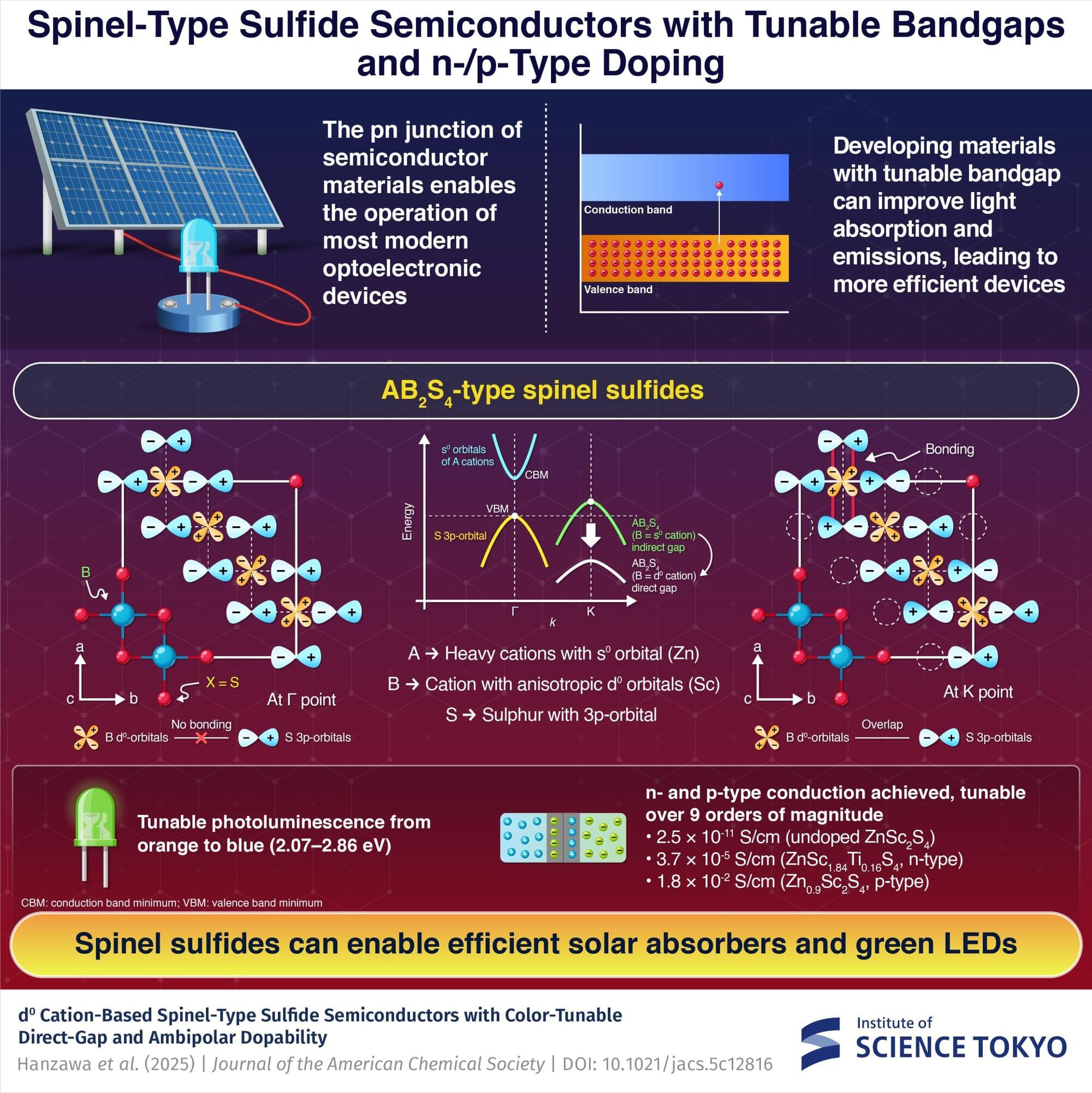

But zoom into the nanoscale—inside the chips that power your smartphone, AI hardware, or next-generation solar panels—and the story changes. Here, heat doesn’t just “diffuse.” It can ripple like sound waves, remember its past, or flow in elegant streams like a fluid in a pipe. For decades, scientists had pieces of this puzzle but no unifying explanation.

Now, researchers at Auburn University and the U.S. Department of Energy’s National Renewable Energy Laboratory have delivered what they call a “unified statistical theory of heat conduction.”