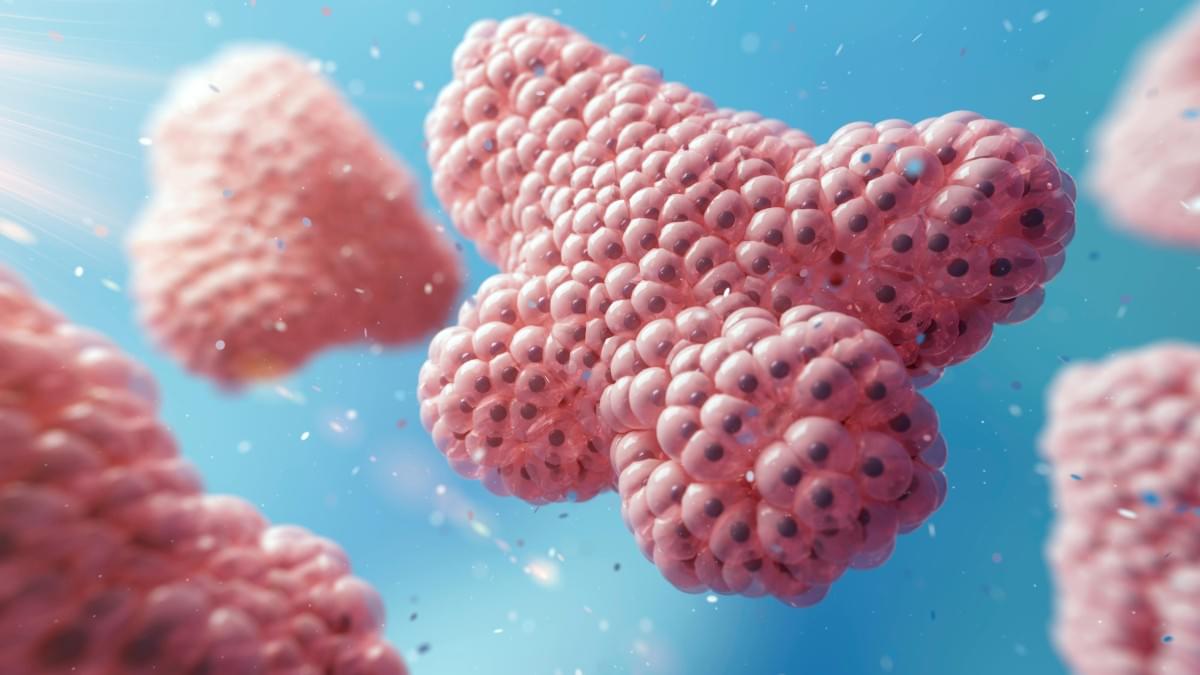

Improved organoid models uncover potential treatments for endocrine-related conditions and reveal new insights into gastrointestinal diseases.

Biannual international conference co-organized by Frédéric Barbaresco and Frank Nielsen. Last updated, February 2025.

Scientific realists hold that we are justified in believing that our best scientific theories are true. But what if those theories are inconsistent? This video examines the argument that realists are committed to believing that there are true contradictions.

I offer private tutoring in philosophy. For details please email me: [email protected].

Support me on Patreon: / kanebaker91

Donate to my PayPal: https://paypal.me/kanebaker91

My Discord: / discord.

0:00 — Introduction.

A new study involving over 700 older adults suggests that taking one gram of omega-3 daily may help slow biological aging, with effects visible in molecular markers known as epigenetic clocks.

When combined with vitamin D and regular exercise, the anti-aging benefits became even more pronounced, lowering the risks of frailty and cancer as well.

Omega-3 linked to slower aging in humans.

All of the cooling methods we’ve discussed so far work by the simple transfer of heat from a hot chip to the surrounding air. This means a chip can never get colder than the ambient temperature of the room it’s in. If we want to cool below ambient temperatures, or if we need to cool something massive like an entire data center, we need to apply some additional science. This is where chillers and thermoelectric coolers come in.

Thermoelectric cooling, also known as a Peltier device, is not very popular at the moment but has the potential to become very useful. These devices transfer heat from one side of a cooling plate to the other by consuming electricity. They use special thermoelectric materials that can create a temperature difference via an electric potential.

When a DC current flows through the device, heat is absorbed from one side and transferred to the other, allowing the “cool” side to drop below ambient temperature. Currently, these devices remain niche because they require a lot of energy to achieve significant cooling. However, researchers are working to develop more efficient versions for broader use.

We use cookies to make sure that our website works properly, as well as some optional cookies to personalise content and advertising, provide social media features and analyse how people use our site. By accepting some or all optional cookies you give consent to the processing of your personal data, including transfer to third parties, some in countries outside of the European Economic Area that do not offer the same data protection standards as the country where you live. You can decide which optional cookies to accept by clicking on “Manage preferences”, where you can also find more information about how your personal data is processed. Further information can be found in our privacy policy.

Dark energy makes up roughly 70% of the universe, yet we know nothing about it.

Around 25% of the universe is the equally mysterious dark matter, leaving just 5% for everything that we can see and touch—matter made up of atoms.

Dark energy is the placeholder name scientists have given to the unknown force causing the universe to expand faster and faster over time.