This new AI acts like a digital scientist, turning messy data into simple rules that explain how the world really works.

Category: robotics/AI – Page 65

France arrests suspect tied to cyberattack on Interior Ministry

French authorities arrested a 22-year-old suspect on Tuesday for a cyberattack that targeted France’s Ministry of the Interior earlier this month.

In a statement issued by Public Prosecutor Laure Beccuau, officials said the suspected hacker was arrested on December 17, 2025, as part of an investigation into the attack.

“A person was arrested on December 17, 2025, as part of the investigation opened by the cybercrime unit of the Paris public prosecutor’s office, on charges including unauthorized access to an automated personal data processing system implemented by the State, committed by an organized group, following the cyberattack against the Ministry of the Interior,” reads the statement translated into English.

Robots that can sense and respond to the world like humans may soon be a reality as scientists have created an artificial neuron capable of mimicking different parts of the brain

Artificial neurons – tiny electronic circuits that replicate the way brain cells communicate – lie at the heart of neuromorphic computing, a field aiming to bring human-like intelligence to machines.

Despite rapid progress, today’s artificial neurons can only perform fixed tasks, each serving a narrow role. Thousands must be combined to replicate simple brain functions – a costly, energy-hungry process compared with the brain’s effortless adaptability.

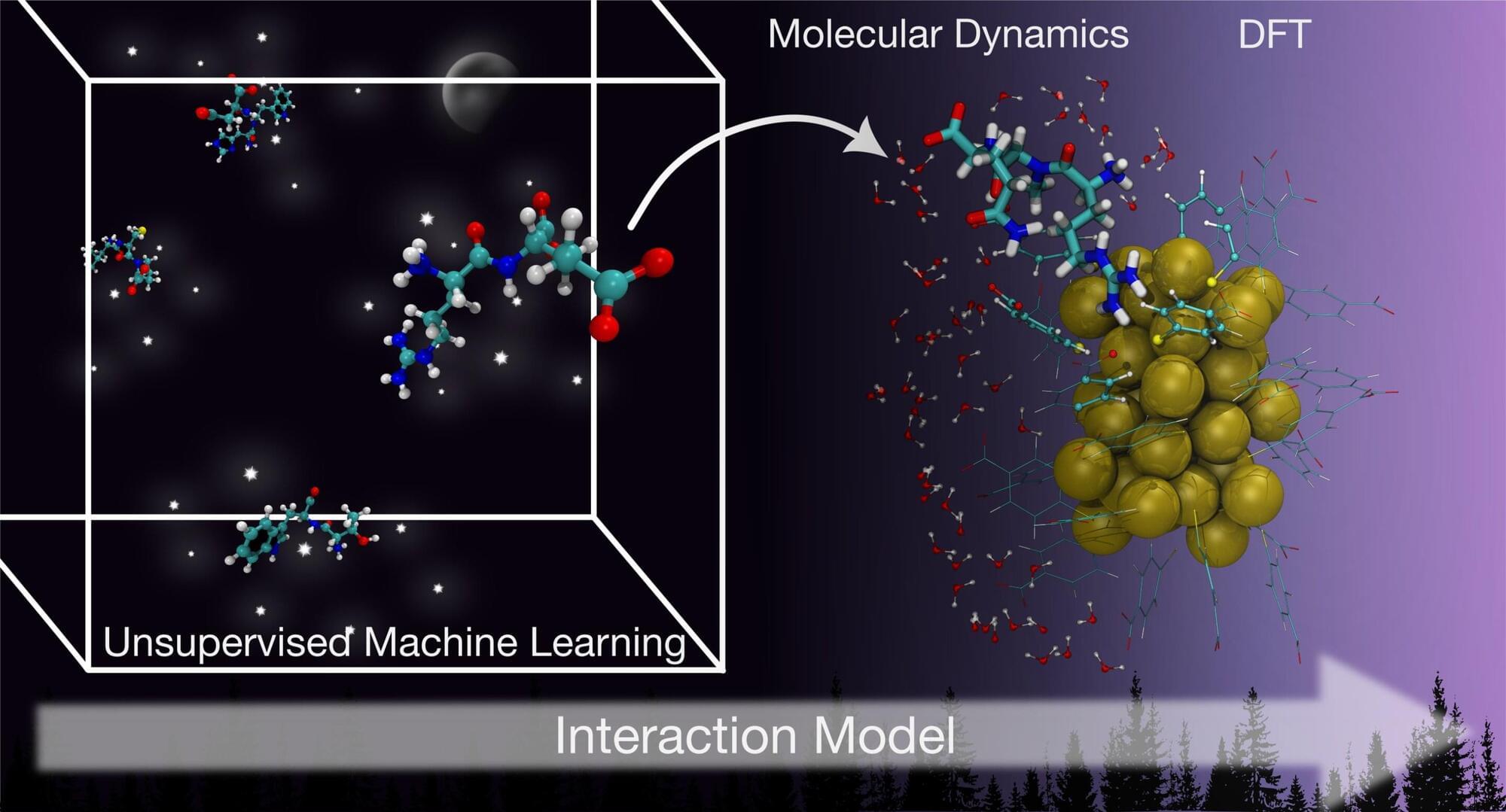

Machine learning model predicts protein binding on gold nanoclusters

Researchers in the Nanoscience Center at the University of Jyväskylä, Finland, have developed a pioneering computational model that could expedite the use of nanomaterials in biomedical applications. The study presented the first generalizable machine-learning framework capable of predicting how proteins interact with ligand-stabilized gold nanoclusters, materials widely employed in bioimaging, biosensing, and targeted drug delivery.

The adsorption of proteins onto nanomaterial surfaces is fundamental to many biological applications, including bioimaging and biosensing to targeted drug delivery. Gold nanoclusters, in particular, have attracted attention thanks to their biocompatibility and tunable optical properties. Yet existing studies that predict how proteins interact with these ligand-protected nanostructures often focus on isolated cases, leaving researchers without a unified model to guide design.

“This gap has created a clear need for general, scalable models capable of capturing the underlying rules of protein–nanocluster binding,” specifies Postdoctoral Researcher Brenda Ferrari from the University of Jyväskylä

Watch: Vine-like robot lifts delicate cargo — including human bodies

Although they’re constantly improving, robots aren’t necessarily known for their gentle touch. A new robotic system from MIT and Stanford takes a unique stab at changing that, with a robot that uses vine-like tendrils to do its lifting.

The system the engineers developed consists of a series of pneumatic tubes that deploy from a pressurized box on one side of a robotic arm, use air pressure to snake under or around a specific object, then rejoin the arm on the other side where they are clamped in place. Once clamped, the arm itself can move, or the tube can be wound up to lift or rotate the object in its grasp. The ability to deploy the tubes and then recapture them is the real breakthrough here, improving on previous vine-based robots by allowing the system to close its own loops.

“People might assume that in order to grab something, you just reach out and grab it,” says study co-author Kentaro Barhydt, from MIT’s Department of Mechanical Engineering. “But there are different stages, such as positioning and holding. By transforming between open and closed loops, we can achieve new levels of performance by leveraging the advantages of both forms for their respective stages.”

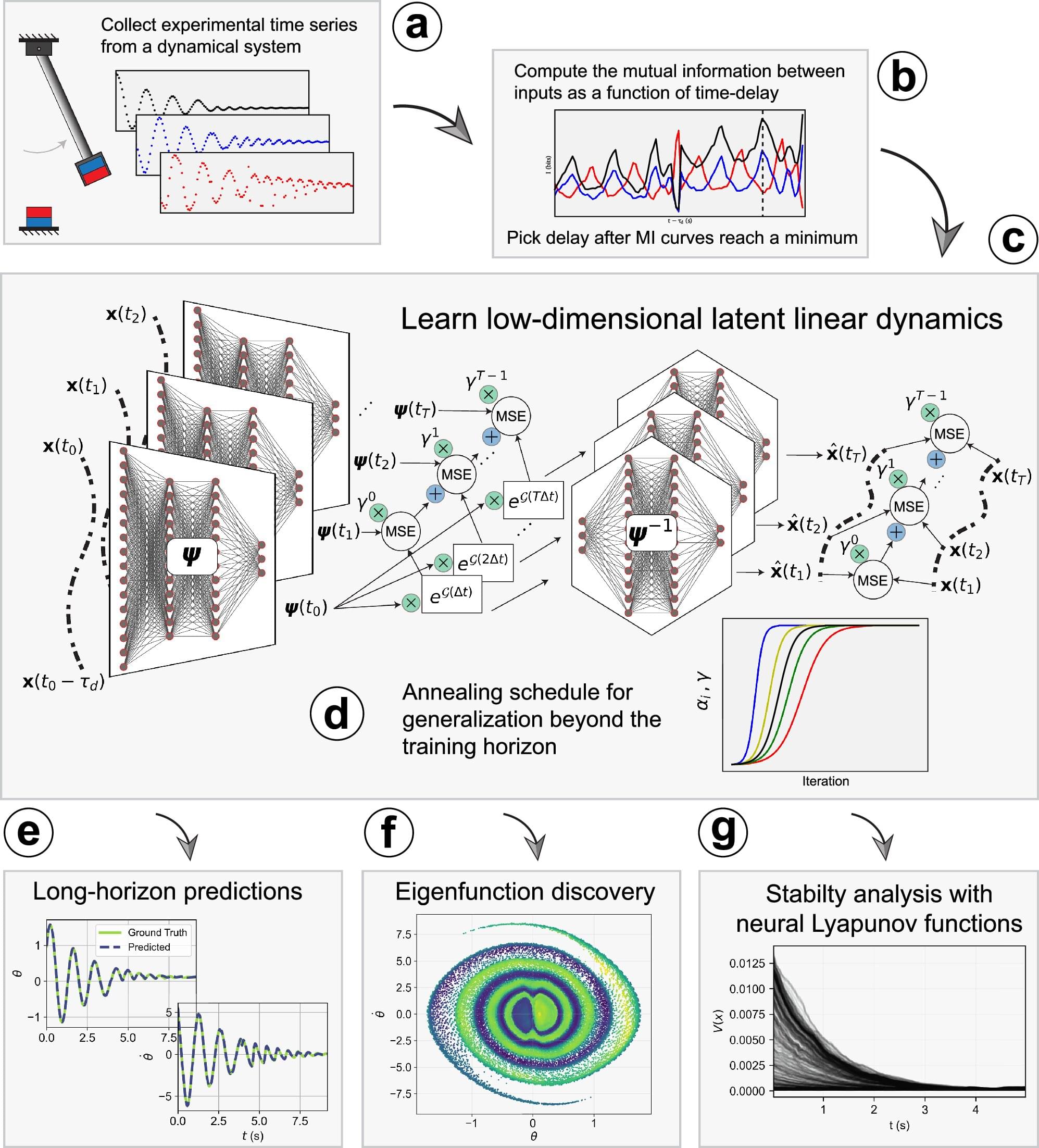

AI learns to build simple equations for complex systems

A research team at Duke University has developed a new AI framework that can uncover simple, understandable rules that govern some of the most complex dynamics found in nature and technology.

The AI system works much like how history’s great “dynamicists”—those who study systems that change over time—discovered many laws of physics that govern such systems’ behaviors. Similar to how Newton, the first dynamicist, derived the equations that connect force and movement, the AI takes data about how complex systems evolve over time and generates equations that accurately describe them.

The AI, however, can go even further than human minds, untangling complicated nonlinear systems with hundreds, if not thousands, of variables into simpler rules with fewer dimensions.

New AI technology can provide rapid and reliable dementia diagnosis

Researchers at Örebro University have developed two new AI models that can analyse the brain’s electrical activity and accurately distinguish between healthy individuals and patients with dementia, including Alzheimer’s disease.

“Early diagnosis is crucial in order to be able to take proactive measures that slow down the progression of the disease and improve the patient’s quality of life,” says Muhammad Hanif, researcher in informatics at Örebro University.