Using the full system, farmers could reduce costs by 40% and chemical usage by up to 95%.

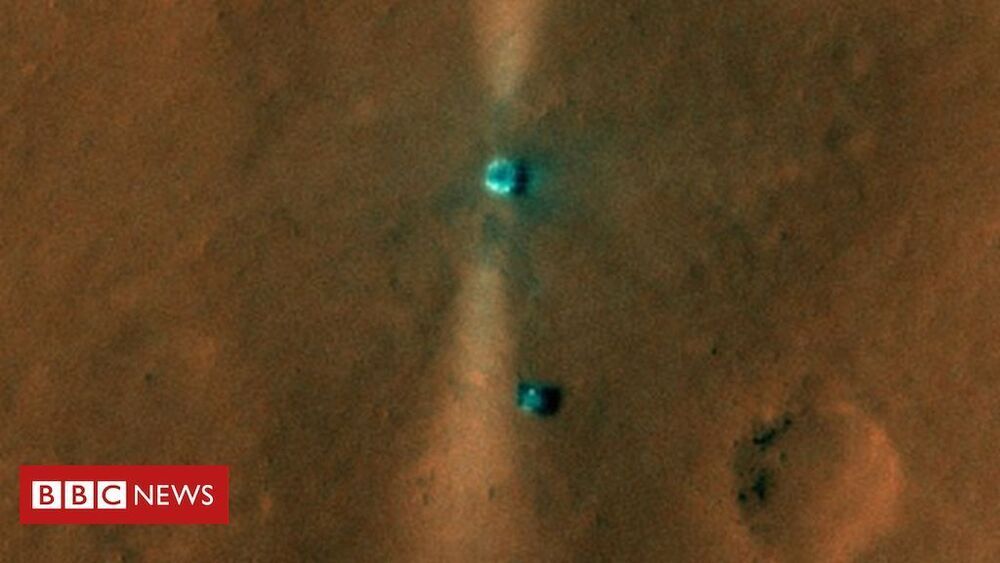

Small Robot Company (SRC), a British agritech startup for sustainable farming, has developed AI-enabled robots – named Tom, Dick and Harry – that identify and kill individual weeds with electricity. These agricultural robots could reduce the use of harmful chemicals and heavy machinery, paving the way for a new approach to sustainable crop farming.

The startup has been working on automated weed killers since 2017, and this April officially launched Tom, the first commercial robot currently operating on three UK farms. Dick is still in the prototype phase, and Harry is still in development.

Small Robot company says the robot Tom is capable of scanning around 20 Hectares per day, collecting about six terabytes of data in an 8-hour shift to identify the crops, spots undesirable weeds – using “Wilma,” an artificial intelligence operating system. This data can then be sent to Dick – the world’s first non-chemical robotic weeding system that zaps individual weeds with electrical ‘lightning strikes.’ And finally, Harry plants seeds in the weed-free soil.