A new study suggests that GPT-4V can interpret social cues in images and video with near-human accuracy. The AI model not only matched human judgments but also predicted brain activity patterns during social perception tasks in fMRI data.

Many attempts have been made to harness the power of new artificial intelligence and large language models (LLMs) to try to predict the outcomes of new chemical reactions. These have had limited success, in part because until now they have not been grounded in an understanding of fundamental physical principles, such as the laws of conservation of mass.

Now, a team of researchers at MIT has come up with a way of incorporating these physical constraints into a reaction prediction model, and thus greatly improving the accuracy and reliability of its outputs.

The new work is reported in the journal Nature, in a paper by recent postdoc Joonyoung Joung (now an assistant professor at Kookmin University, South Korea); former software engineer Mun Hong Fong (now at Duke University); chemical engineering graduate student Nicholas Casetti; postdoc Jordan Liles; physics undergraduate student Ne Dassanayake; and senior author Connor Coley, who is the Class of 1957 Career Development Professor in the MIT departments of Chemical Engineering and Electrical Engineering and Computer Science.

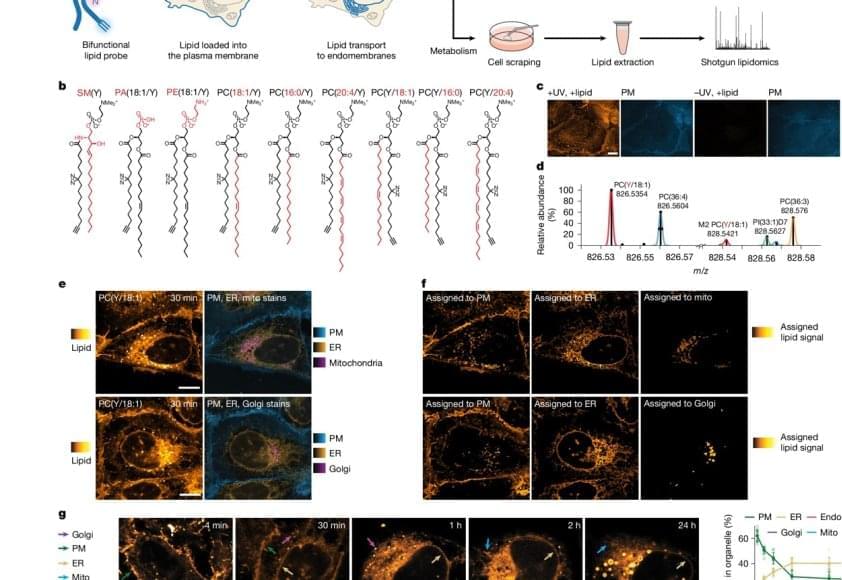

Lipid molecules, or fats, are crucial to all forms of life. Cells need lipids to build membranes, separate and organize biochemical reactions, store energy, and transmit information. Every cell can create thousands of different lipids, and when they are out of balance, metabolic and neurodegenerative diseases can arise. It is still not well understood how cells sort different types of lipids between cell organelles to maintain the composition of each membrane. A major reason is that lipids are difficult to study, since microscopy techniques to precisely trace their location inside cells have so far been missing.

The researchers developed a method that enables visualizing lipids in cells using standard fluorescence microscopy. After the first successful proof of concept, the authors brought mass-spectrometry expert on board to study how lipids are transported between cellular organelles.

“We started our project with synthesizing a set of minimally modified lipids that represent the main lipids present in organelle membranes. These modified lipids are essentially the same as their native counterparts, with just a few different atoms that allowed us to track them under the microscope,” explains a PhD student in the group.

The modified lipids mimic natural lipids and are “bifunctional,” which means they can be activated by UV light, causing the lipid to bind or crosslink with nearby proteins. The modified lipids were loaded in the membrane of living cells and, over time, transported into the membranes of organelles. The researchers worked with human cells in cell culture, such as bone or intestinal cells, as they are ideal for imaging.

“After the treatment with UV light, we were able to monitor the lipids with fluorescence microscopy and capture their location over time. This gave us a comprehensive picture of lipid exchange between cell membrane and organelle membranes,” concludes the author.

In order to understand the microscopy data, the team needed a custom image analysis pipeline. “To address our specific needs, I developed an image analysis pipeline with automated image segmentation assisted by artificial intelligence to quantify the lipid flow through the cellular organelle system,” says another author.

By combining the image analysis with mathematical modeling, the research team discovered that between 85% and 95% of the lipid transport between the membranes of cell organelles is organized by carrier proteins that move the lipids, rather than by vesicles. This non-vesicular transport is much more specific with regard to individual lipid species and their sorting to the different organelles in the cell. The researchers also found that the lipid transport by proteins is ten times faster than by vesicles. These results imply that the lipid compositions of organelle membranes are primarily maintained through fast, species-specific, non-vesicular lipid transport.

In 3D bioprinting, researchers use living cells to create functional tissues and organs. Instead of printing with plastic, they print with living cells. This comes with great challenges. Cells are fragile and wouldn’t survive a regular 3D printing process. That’s why Levato’s team developed a special bio-ink, a mix of living cells and nourishing gels that protect the cells during the printing process.

With the advancements in bio-inks, layer-by-layer 3D bioprinting became possible. But this method is still time-consuming and puts a lot of stress on the cells. Researchers from Utrecht came up with a solution: volumetric bioprinting.

Volumetric bioprinting is faster and gentler on cells. Using cell-friendly laser light, a 3D structure is created all at once. “To build a structure, we project a series of light patterns into a spinning tube filled with light-sensitive gel and cells,” Levato explains. “Where the light beams converge, the material solidifies. This creates a full 3D object in one go, without having to touch the cells.” To do this, it is crucial to know exactly where the cells are in the gel. GRACE now makes that possible.

Questions to inspire discussion.

💼 Q: How could Elon Musk’s ownership stake in Tesla change with this package? A: Musk’s ownership could increase to over 25% if he achieves all 12 tranches, potentially taking 10 years to complete, with voting rights granted earlier upon milestone achievement.

📊 Q: What is the significance of the proxy vote on September 15th? A: The proxy vote determines share count and equity incentive plan, potentially giving Musk voting rights for remaining shares from the 2018 package, accelerating his path to 20% ownership.

Tesla’s Growth and Profitability Targets.

📈 Q: What is Tesla’s final profitability target in the compensation plan? A: The plan targets $400 billion in EBITDA, comparable to Meta, Alphabet, and Microsoft at their $8.5 trillion market cap, suggesting Tesla’s potential value could reach $15–16 trillion.

🚗 Q: What are the specific product-related milestones in the plan? A: Key milestones include 20 million vehicles delivered, 10 million FSD subscriptions, 1 million robo taxis deployed, and 1 million bots delivered over a 5–10 year timeframe.

Questions to inspire discussion.

🌐 Q: How quickly will Tesla expand its robo taxi service? A: Tesla plans to rapidly expand access to its ride-hailing service in the Bay Area and robo taxi service in Austin, Texas, by scaling its fleet and improving autonomous driving technology.

🚕 Q: What impact will Tesla’s robo taxi service have on the ride-hailing industry? A: Tesla’s service is expected to disrupt traditional ride-hailing, potentially becoming the most cost-effective option for customers while advancing sustainable energy transition.

Revenue and Profitability.

📈 Q: How will the robo taxi service affect Tesla’s revenue? A: The service is anticipated to generate significant revenue for Tesla, leveraging its cost advantage and autonomous technology to become potentially the most profitable ride-hailing option.

🔋 Q: How does the robo taxi service align with Tesla’s broader mission? A: The service supports Tesla’s ambition statement of accelerating the world’s transition to sustainable energy while offering a competitive and cost-effective transportation solution.

A debate/discussion on ASI (artificial superintelligence) between Foresight Senior Fellow Mark S. Miller and MIRI founder Eliezer Yudkowsky. Sharing similar long-term goals, they nevertheless reach opposite conclusions on best strategy.

“What are the best strategies for addressing risks from artificial superintelligence? In this 4-hour conversation, Eliezer Yudkowsky and Mark Miller discuss their cruxes for disagreement. While Eliezer advocates an international treaty that bans anyone from building it, Mark argues that such a pause would make an ASI singleton more likely – which he sees as the greatest danger.”

What are the best strategies for addressing extreme risks from artificial superintelligence? In this 4-hour conversation, decision theorist Eliezer Yudkowsky and computer scientist Mark Miller discuss their cruxes for disagreement.

They examine the future of AI, existential risk, and whether alignment is even possible. Topics include AI risk scenarios, coalition dynamics, secure systems like seL4, hardware exploits like Rowhammer, molecular engineering with AlphaFold, and historical analogies like nuclear arms control. They explore superintelligence governance, multipolar vs singleton futures, and the philosophical challenges of trust, verification, and control in a post-AGI world.

Moderated by Christine Peterson, the discussion seeks the least risky strategy for reaching a preferred state amid superintelligent AI risks. Yudkowsky warns of catastrophic outcomes if AGI is not controlled, while Miller advocates decentralizing power and preserving human institutions as AI evolves.

In the 17th century, German astronomer Johannes Kepler figured out the laws of motion that made it possible to accurately predict where our solar system’s planets would appear in the sky as they orbit the sun. But it wasn’t until decades later, when Isaac Newton formulated the universal laws of gravitation, that the underlying principles were understood.

Although they were inspired by Kepler’s laws, they went much further, and made it possible to apply the same formulas to everything from the trajectory of a cannon ball to the way the moon’s pull controls the tides on Earth—or how to launch a satellite from Earth to the surface of the moon or planets.

Today’s sophisticated artificial intelligence systems have gotten very good at making the kind of specific predictions that resemble Kepler’s orbit predictions. But do they know why these predictions work, with the kind of deep understanding that comes from basic principles like Newton’s laws?