Abstract of full article w/ downloadable pdf:

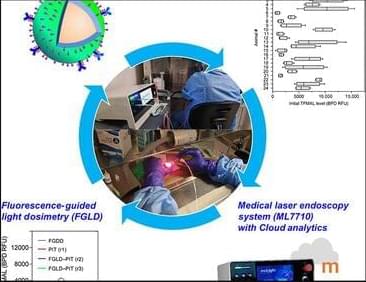

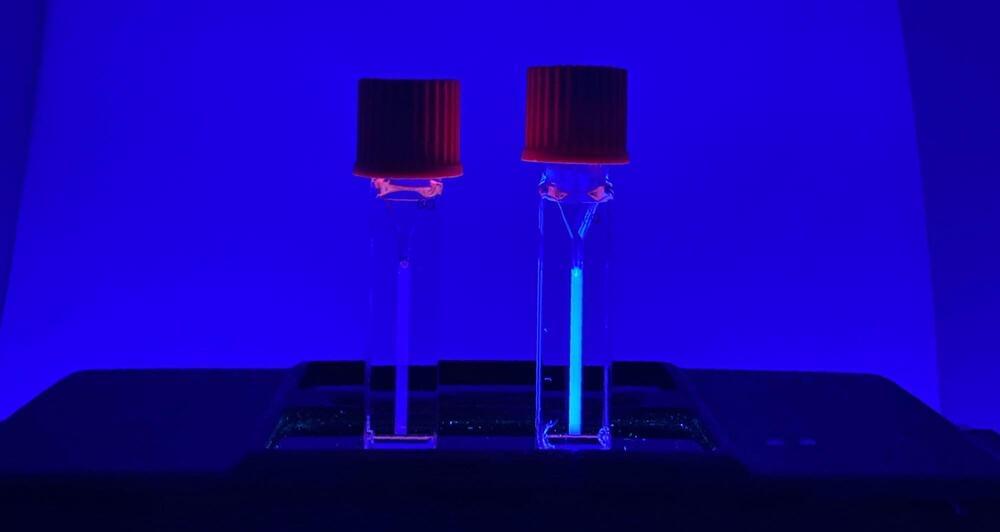

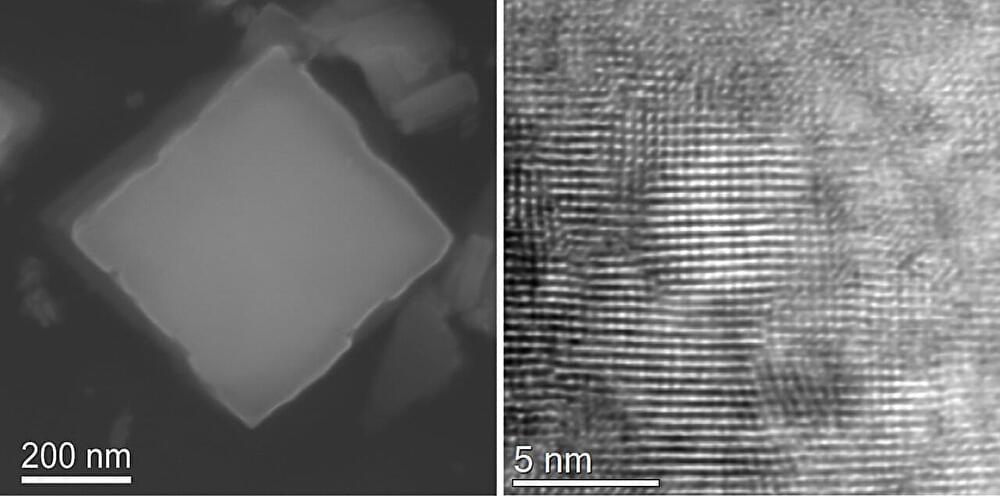

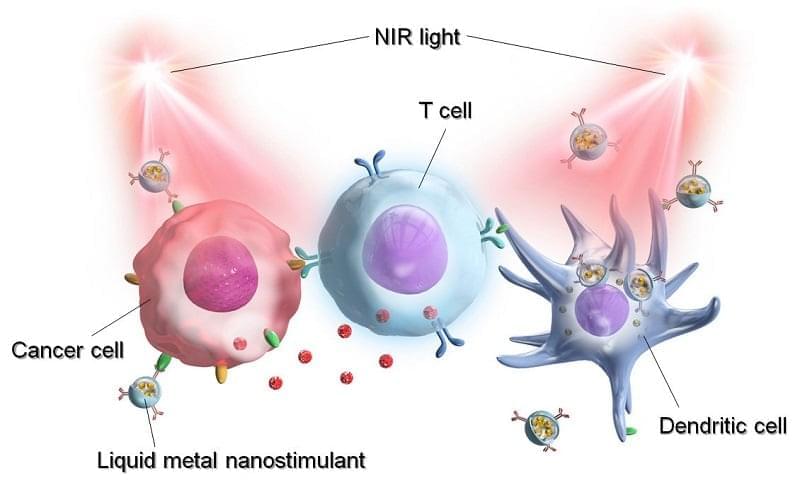

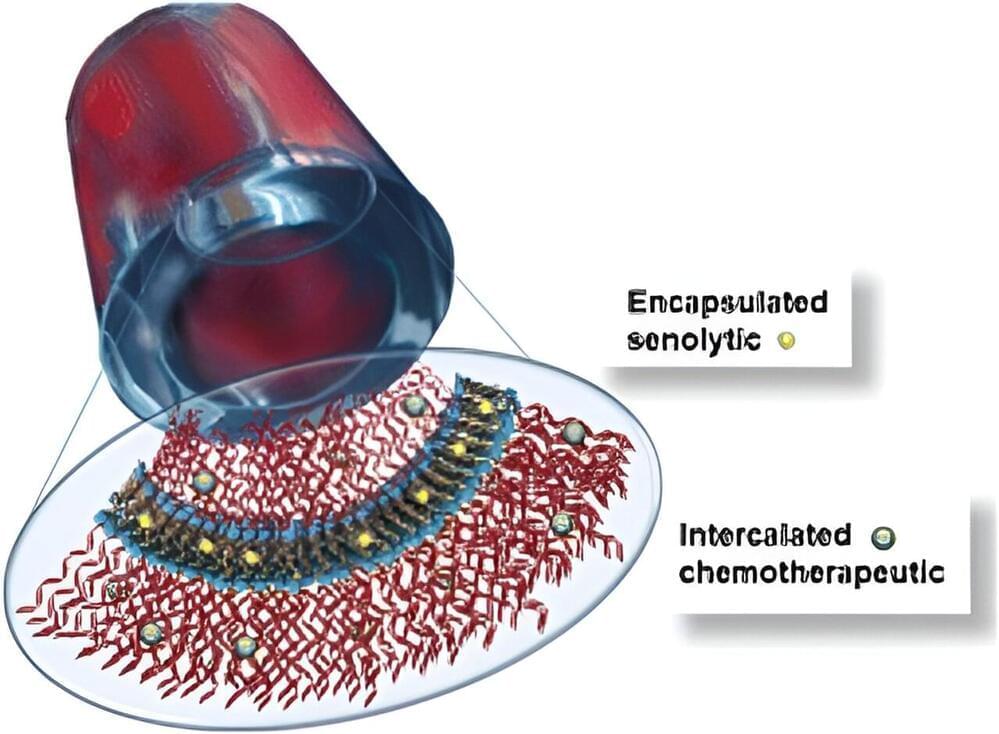

Fluorescence-guided intervention can bolster standard therapies by detecting and treating microscopic tumors before lethal recurrence. Tremendous progress in photoimmunotherapy and nanotechnology has been made to treat metastasis. However, many are lost in translation due to heterogeneous treatment effects. Here, we integrate three technological advances in targeted photo-activable multi-agent liposome (TPMAL), fluorescence-guided intervention, and laser endoscopy (ML7710) to improve photoimmunotherapy. TPMAL consists of a nanoliposome chemotherapy labeled with fluorophores for tracking and photosensitizer immunoconjugates for photoimmunotherapy… More.

Fluorescence-guided photoimmunotherapy using nanotechnology and ML7710 reduces heterogeneous therapy effects and tumor metastasis.