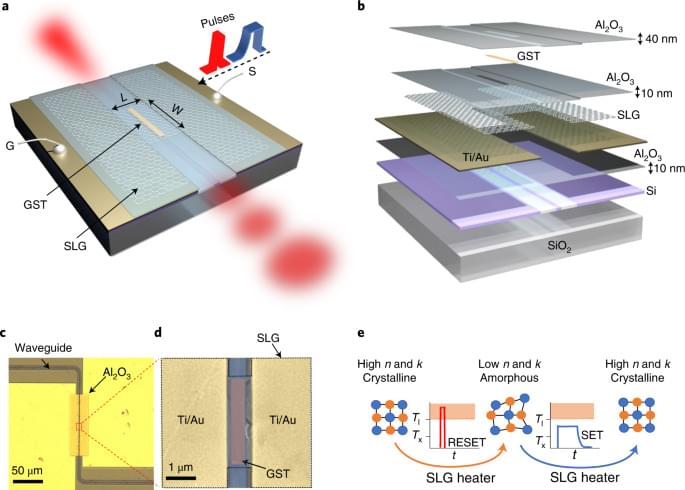

The ability to turn superconductivity off and on with a literal flip of a switch in so-called “magic-angle twisted graphene” has allowed engineers at Caltech to observe an unusual phenomenon that may shed new light on superconductivity in general.

The research, led by Stevan Nadj-Perge, assistant professor of applied physics and materials science, was published in the journal Nature on June 15.

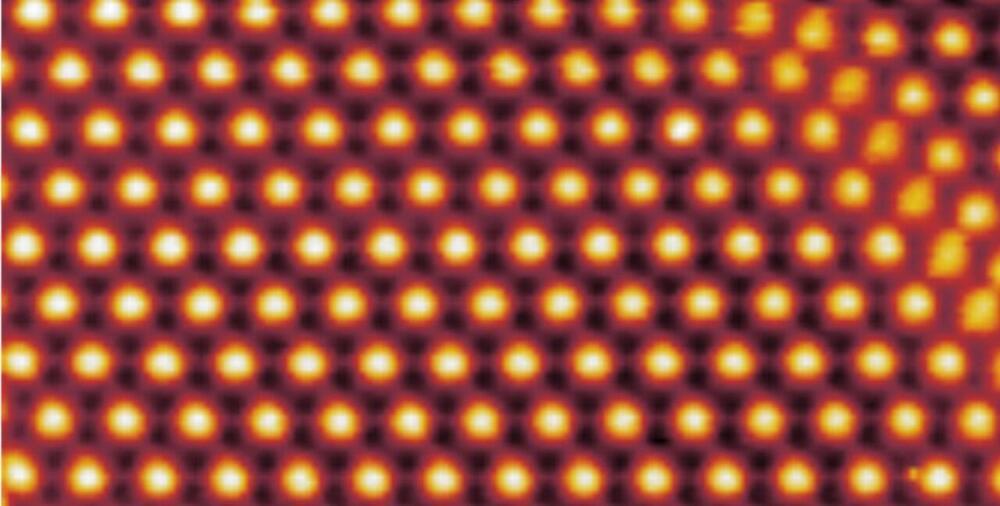

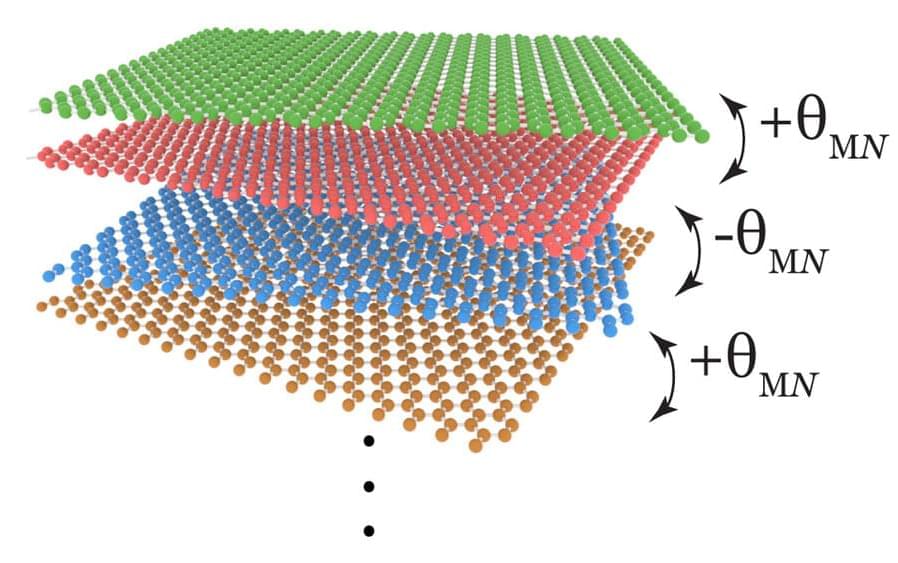

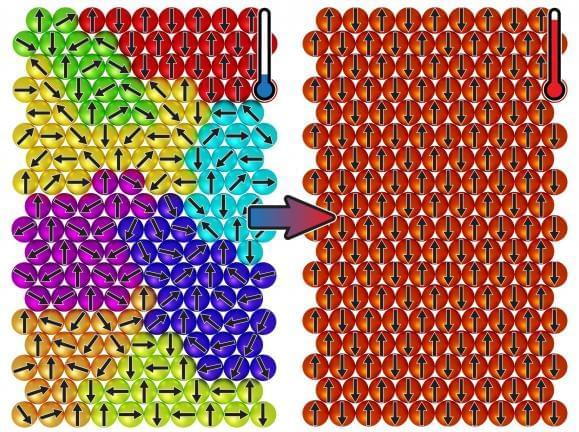

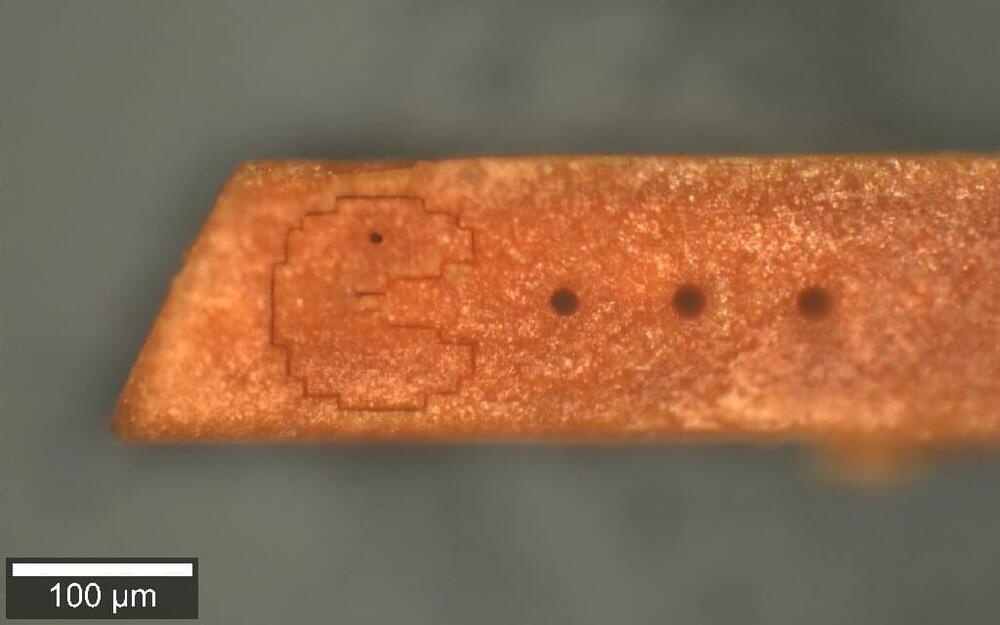

Magic-angle twisted graphene, first discovered in 2018, is made from two or three sheets of graphene (a form of carbon consisting of a single layer of atoms in a honeycomb-like lattice pattern) layered atop one another, with each sheet twisted at precisely 1.05 degrees in relation to the one below it. The resulting bilayer or trilayer has unusual electronic properties: for example, it can be made into an insulator or a superconductor depending on how many electrons are added.