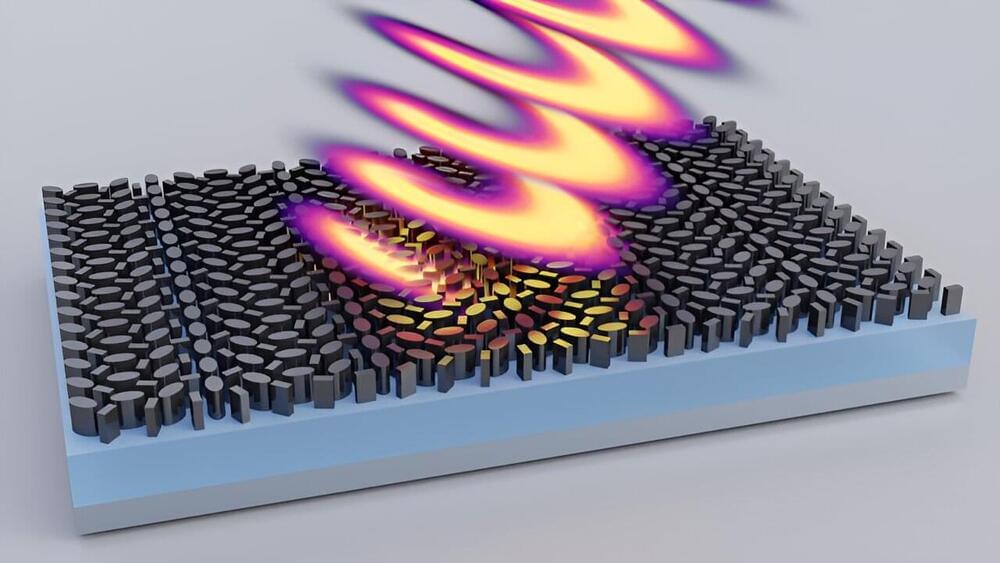

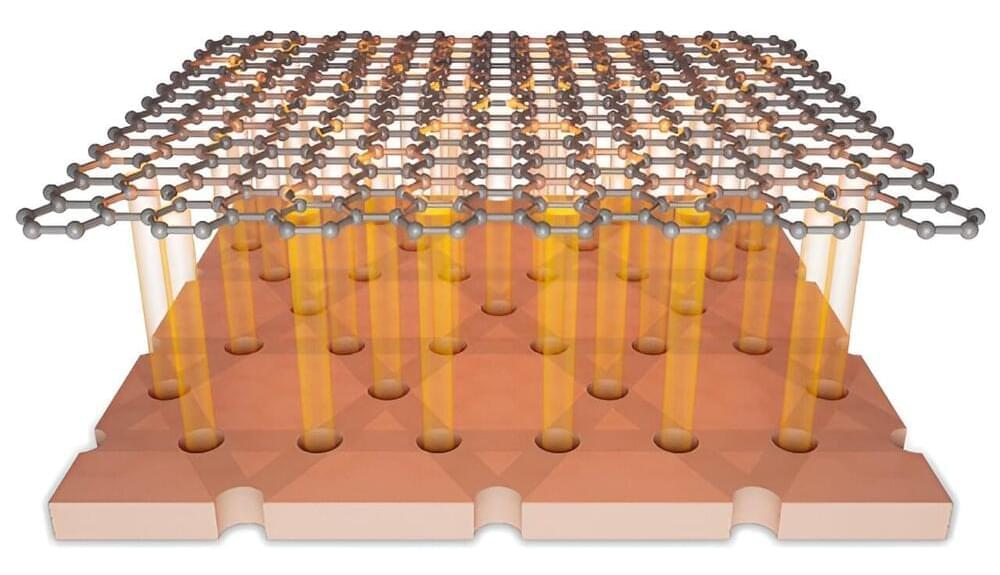

Researchers at Swansea University, in collaboration with Wuhan University of Technology, Shenzhen University, have developed a pioneering technique for producing large-scale graphene current collectors.

This breakthrough promises to significantly enhance the safety and performance of lithium-ion batteries (LIBs), addressing a critical challenge in energy storage technology.

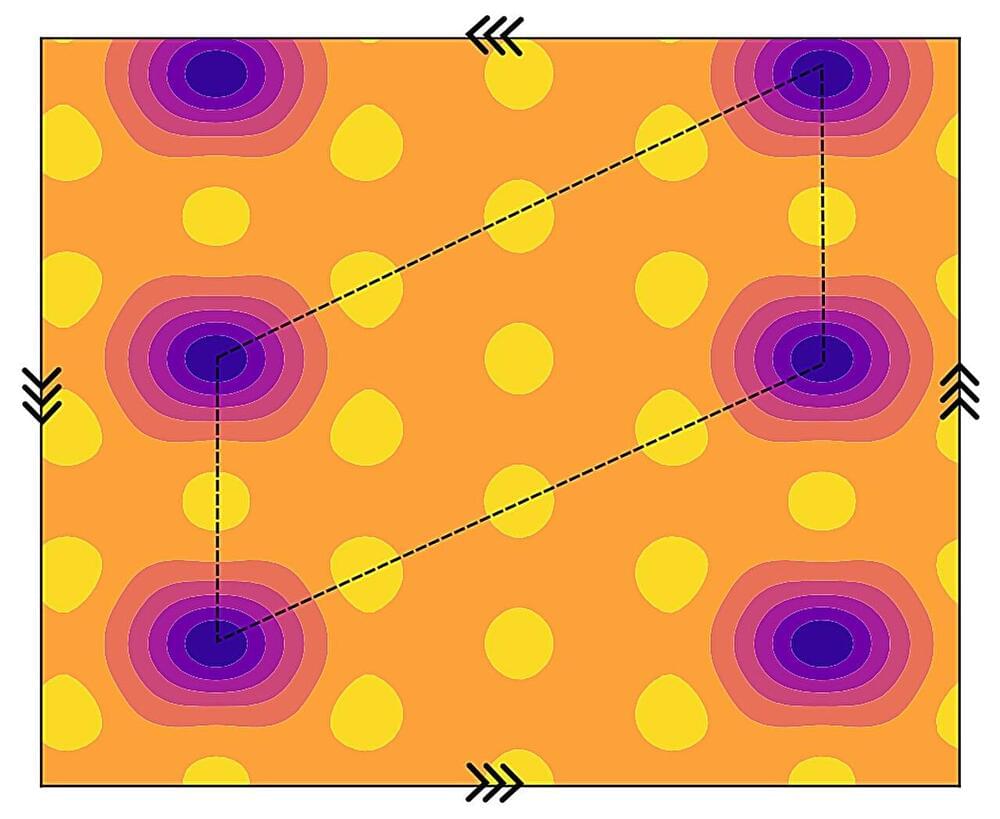

Published in Nature Chemical Engineering, the study details the first successful protocol for fabricating defect-free graphene foils on a commercial scale. These foils offer extraordinary thermal conductivity—up to 1,400.8 W m–1 K–1 —nearly ten times higher than traditional copper and aluminum current collectors used in LIBs.