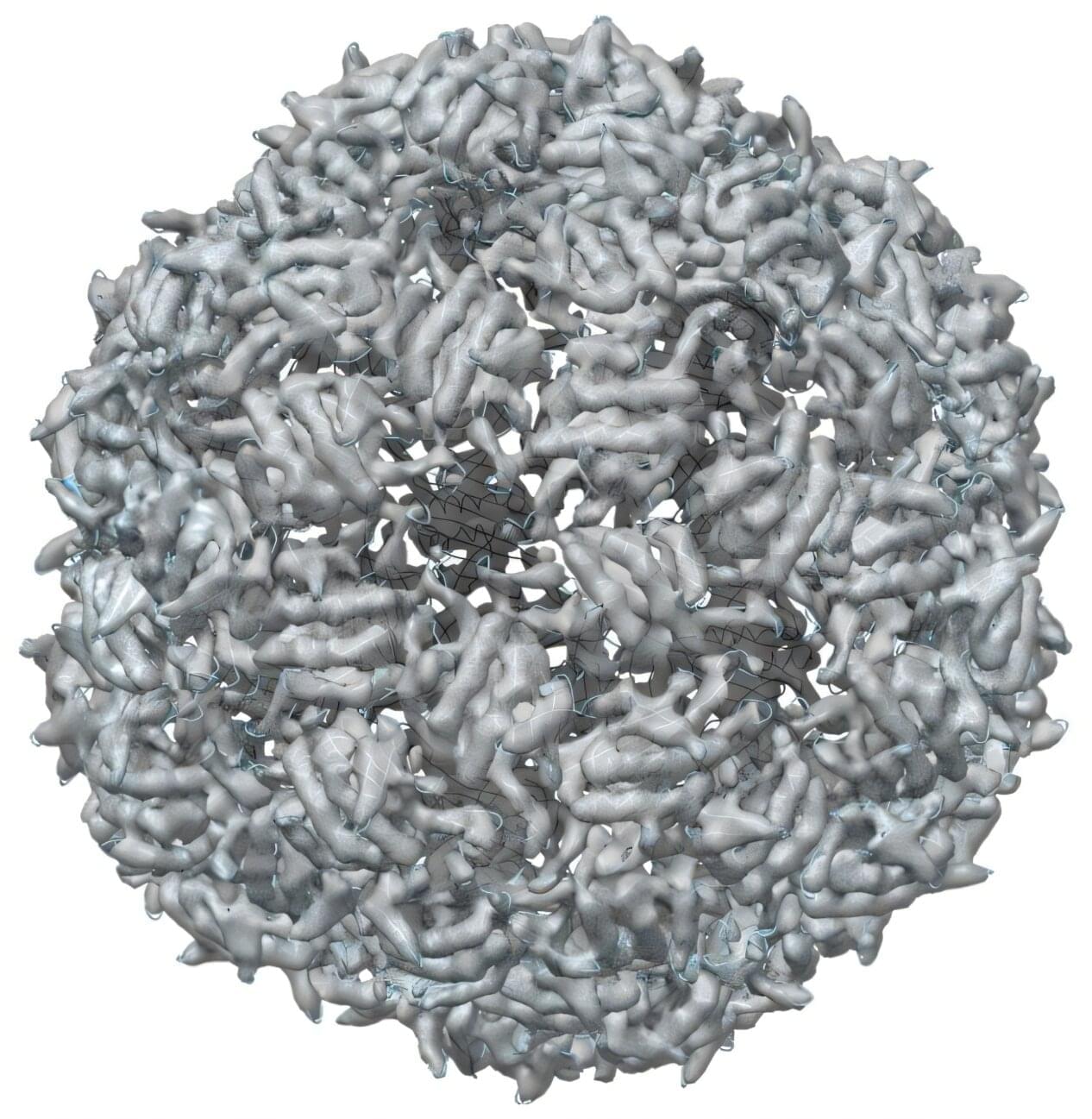

Electron microscopy is an exceptional tool for peering deep into the structure of isolated molecules. But when it comes to imaging thicker biological samples to understand how those molecules function in their cellular environments, the technology gets a little murky.

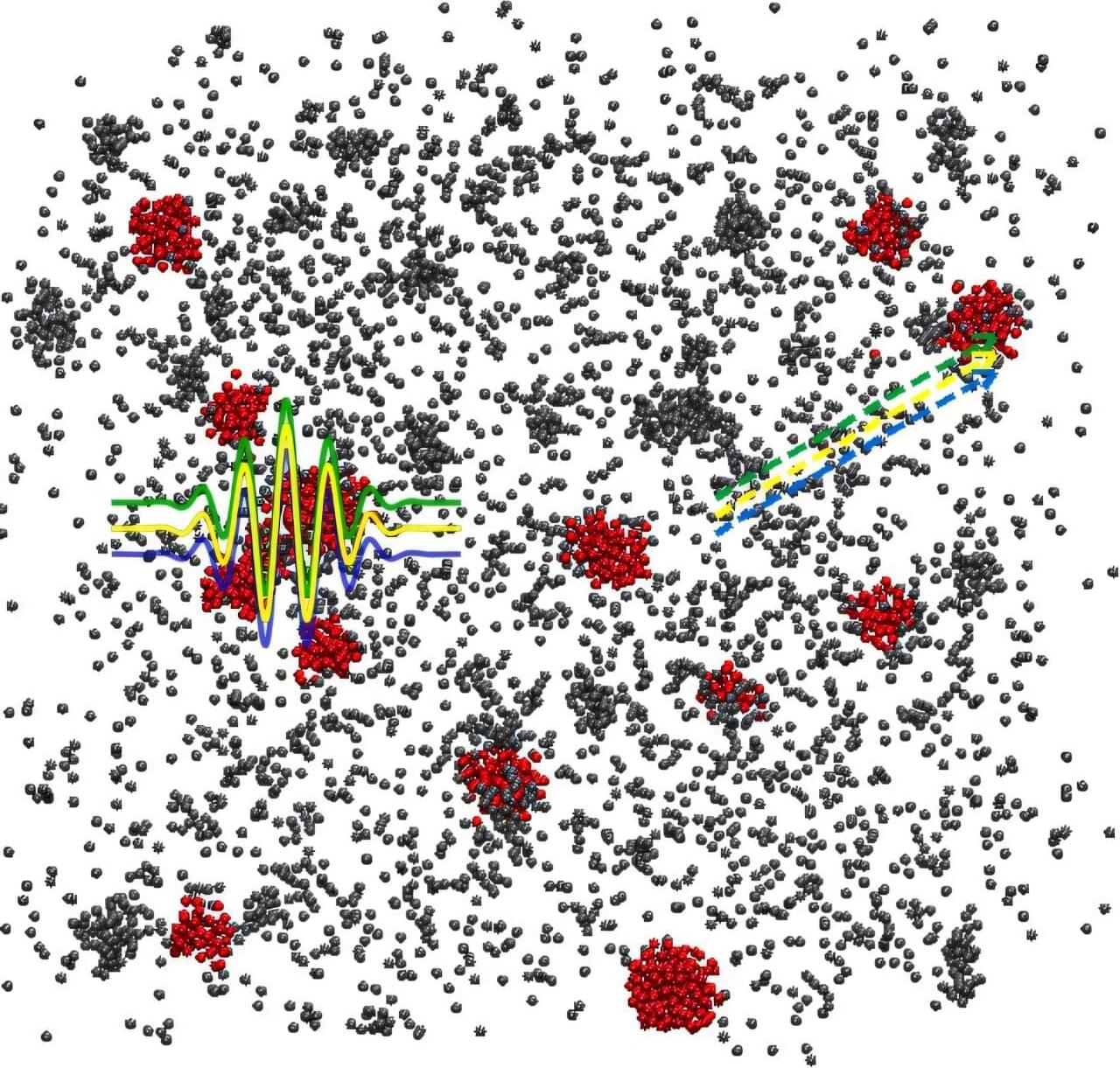

Cornell researchers devised a new method, called tilt-corrected bright-field scanning transmission electron microscopy (tcBF-STEM), to image thick samples with higher contrast and a fivefold increase in efficiency.

The Sept. 23 publication of the findings, in Nature Methods, arrives two years after the death of co-author Lena Kourkoutis, M.S. ‘06, Ph.D. ‘09, associate professor in applied and engineering physics in Cornell Engineering, whose work in cryo-electron microscopy drove much of the nearly 10-year effort.