Ultrasound is more tissue-friendly and less absorbed by the body, making it a reliable option for powering implantable and skin-adherent devices. As a result, ultrasonic energy is emerging as a next-generation solution for wireless charging.

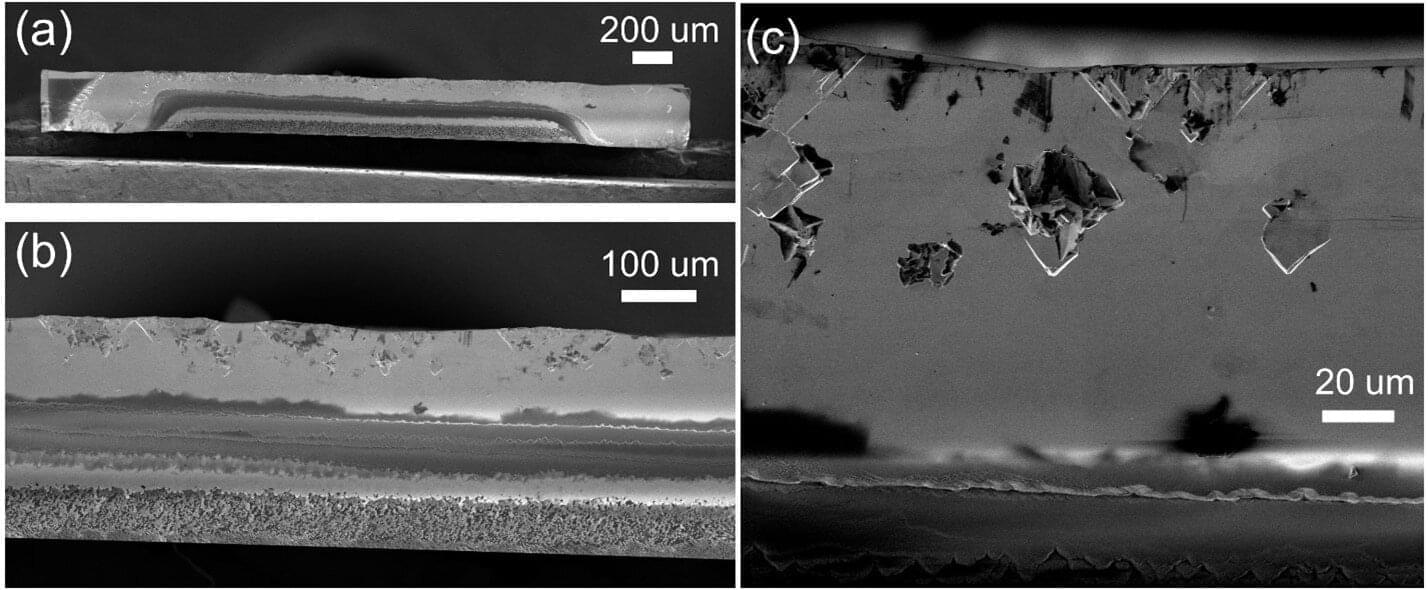

A flexible, biocompatible solution

A research team led by Dr. Sunghoon Hur from the Electronic and Hybrid Materials Research Center at the Korea Institute of Science and Technology (KIST), along with Professor Hyun-Cheol Song of Korea University, has developed a biocompatible ultrasonic receiver that maintains consistent performance even when bent.