Companies specializing in cutting-edge construction techniques are aiming to make a difference by churning out high-quality homes at a lower cost than traditional industry standards. Among these are 3D printed homes, “foldable” homes, and homes that ship in kits then are assembled like Ikea furniture.

Now a new player is joining the list, and it just got a serious financial boost. Vantem Global has already helped construct a total of over three million square feet of living space in six different countries, and earlier this month closed a Series A funding round co-led by Breakthrough Energy Ventures (Breakthrough was founded by Bill Gates in 2015 to invest in sustainable energy and emissions-reduction technologies).

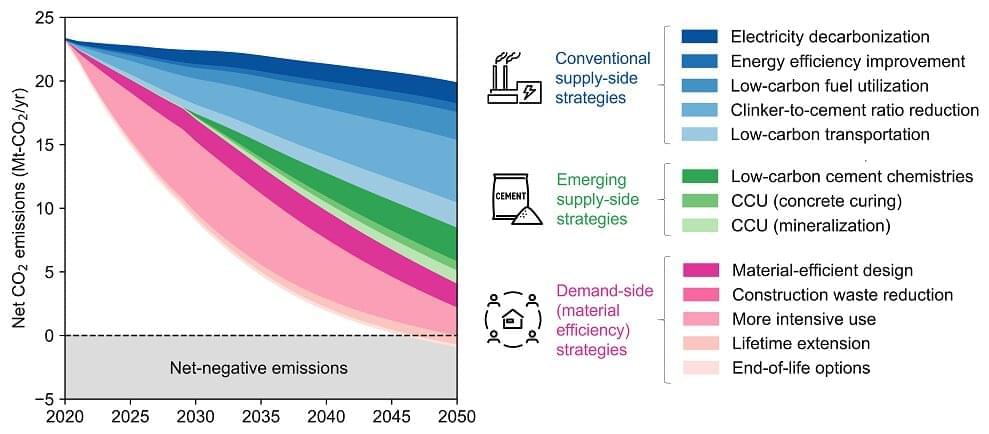

Vantem’s energy-efficient prefabricated homes are made of structural panels. The panels were designed as a replacement for brick and cement, which are expensive, difficult to make, and heavy on emissions. Each panel consists of an insulating layer sandwiched by tiles made of a cement-like material. Since the panels are more similar to cement than wood or plastic are, they’re more likely to be positively perceived by customers who are used to cement (as many in Latin America are, where Vantem has thus far focused most of its construction).