Abandoned mine shafts like this one can be turned into giant storage batteries.

The technology uses the vertical drop in abandoned mine shafts to generate zero-emission electricity.

We’ve got a new kind of ice on the block – medium-density amorphous ice (MDA).

It’s amorphous, which means that the water molecules are in a disorganised form instead of being neatly ordered like they are in the ordinary, crystalline ice you find floating in your Scotch on the rocks…

Amorphous ice is super rare on Earth, but scientists think that it might be the main type found in the frigid environment of outer space – because ice wouldn’t have enough thermal energy there to form crystals.

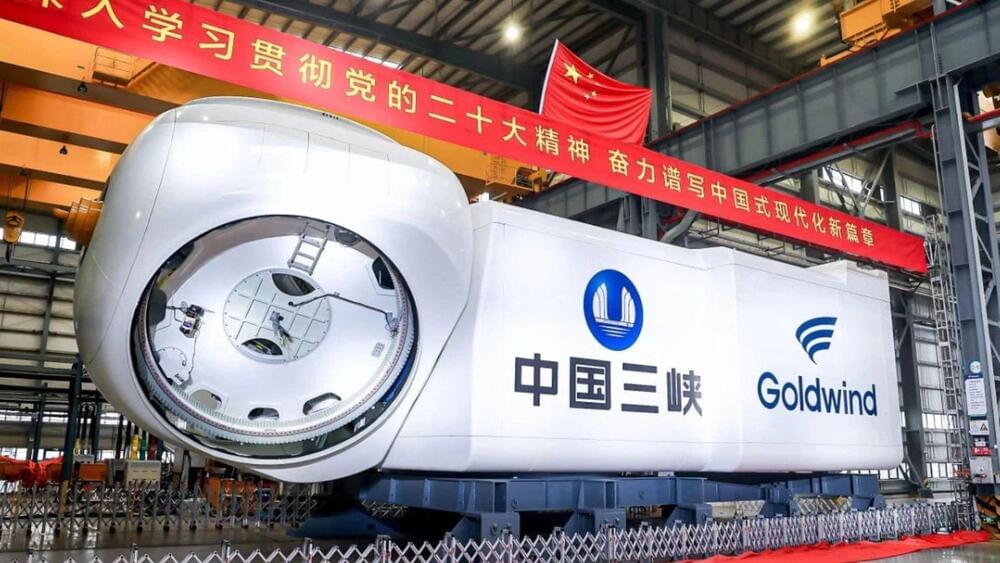

The offshore wind farm is expected to lower China’s carbon dioxide emissions by 1.36 million tonnes and claims to provide more than 1.6 billion kilowatts of power annually.

China claims to have begun the construction of its first extensive offshore wind farm using 16-megawatt turbines on Saturday.

This represents a significant change from the smaller, less effective turbines that China’s offshore wind farms have often employed, claimed a report on Sunday by China Global Television Network (CGTN), a state-run media.

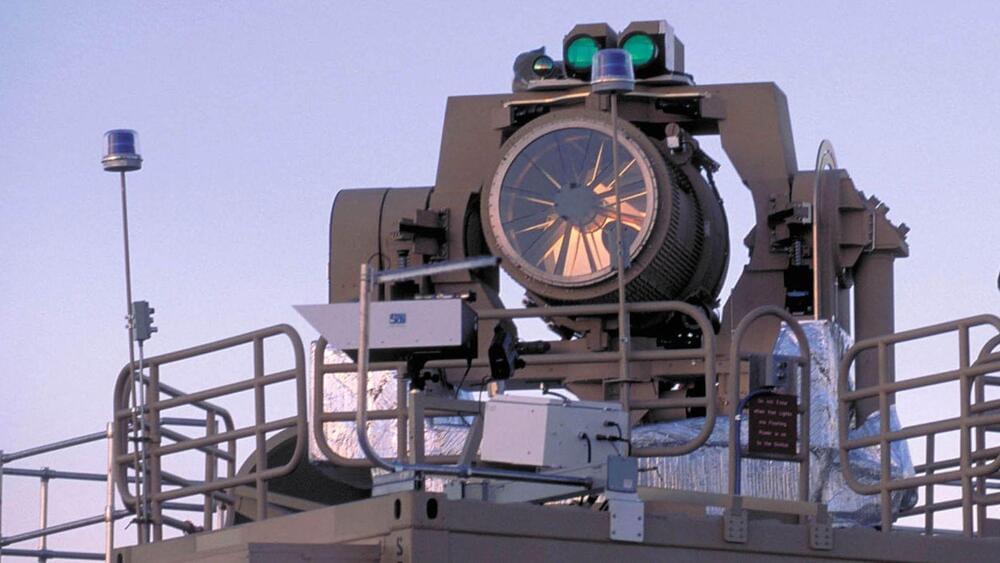

“If this technology finds an application in power generation, we may owe the hypersonic weapons a big ‘thank you,’” says a researcher.

A team of researchers from Beijing has created a generator “capable” of converting hot gas at hypersonic speeds into a powerful electric current.

The researchers claimed that the magnetohydrodynamics (MHD) generator yielded more than ten times the power generated in previous experiments.

Wikimedia Commons.

The electricity generated can be used to power military lasers, microwave weapons, rail guns, and other pulsed energy weapons, South China Morning Post (SCMP) reported on Thursday.

In a bid to make wood stronger and lighter than glass to move towards an energy-efficient future, a team of researchers at the University of Maryland has found a new way to make wood completely transparent which they believe to be better than the previous techniques.

The paper, published in the journal Science Advances, details the making of their transparent wood which was found to be 50 times stronger than the ones made using the conventional way.

This is the BMW electric wingsuit 2021.

BMW Group will present the first electric drive system for a wingsuit with which the centuries-old dream of flying can be realised in a completely novel way. The innovative drive module and the likewise entirely newly designed wingsuit were developed in a cooperation between BMW i, Designworks and the professional wingsuit pilot Peter Salzmann from Austria. His maiden flight with the Electrified Wingsuit by BMW i was visually captured in an elaborately staged video documentation. The spectacular film, which will be seen for the first time in the run-up to the #NEXTGen 2020, shows impressively how BMW eDrive technology is able to make a lasting change to the individual mobility experience.

The long-term experience and the BMW i brand’s pooled development competence have now been utilised in a completely innovative way. The result is an extremely powerful, compact and light drive and energy storage package for a unique flying experience with the Electrified Wingsuit by BMW i. The fly unit of the Electrified Wingsuit by BMW i comprises two encased carbon propellers, so-called impellers, each delivering a power output of 7.5 kW, a speed of around 25,000 rpm and a total output of 15 kW, which is available for approximately 5 minutes. The design of the drive unit and the likewise exclusively developed wingsuit is the result of a cooperation between Peter Salzmann and the creative team from Designworks. The BMW Group subsidiary has strongly influenced the BMW i brand’s design from the outset, applying its creative capabilities not only in the automotive sector, but also on behalf of numerous international clients from other branches of industry.

Around 3 years passed from the idea of a wingsuit flight with electric extra boost to the premiere in the Austrian alps. During this time the air sports pioneer Peter Salzmann and his partners at BMW i and Designworks worked jointly on the details of the suit and the drive system. The electric twin-propeller drive system including an energy storage unit were perfectly integrated into the front of the wing suit. The tests in the wind tunnel at the BMW Group Aerodynamics Testing Centre in Munich were a significant part of the development programme for the project.

The project Electrified Wingsuit by BMW i was triggered by Peter Salzmann’s aspiration to raise wingsuit sport to a new level. The 33-year-old Austrian is a skydiving instructor and has meanwhile also made base jumping and skydiving his profession. In addition to skydiving training and wingsuit flying, his repertoire includes film stunts and show appearances. When jumping from cliffs or out of an aircraft, Salzmann uses the textile layer stretched between the arms and legs of his wingsuit as a paraglider that allows him to generate a horizontal flight movement from the fall velocity and the airflow. With each metre of descent, up to three metres of horizontal flight can be achieved. Wingsuit skydivers can reach speeds of more than 100 km/h.

The aim of the electric drive system is to increase the performance of the wingsuit in order to achieve a better constant glide flight, thus allowing longer distances to be covered. Upon activation, Salzmann explains, the pilot experiences immediate acceleration, allowing them to fly at speeds of more than 300 km/h. For the maiden flight with the Electrified Wingsuit by BMW i Salzmann was flown by helicopter together with two other wingsuit pilots over the mountain tops of his Austrian homeland. Directly after the jump from an altitude of 3,000 metres, all three flew in formation in the direction of a mountain massif. With the aid of the electric drive Salzmann accelerated faster than his colleagues and was able to fly across the peak in steep flight. After flying a further curve, he met up with the other two pilots who had flown in glide flight around the mountain. The three wingsuit pilots finally opened their parachutes and landed at the agreed destination.

Researchers at UCL and the University of Cambridge have discovered a new type of ice that more closely resembles liquid water than any other known ices and that may rewrite our understanding of water and its many anomalies.

The newly discovered ice is amorphous—that is, its molecules are in a disorganized form, not neatly ordered as they are in ordinary, crystalline ice. Amorphous ice, although rare on Earth, is the main type of ice found in space. That is because in the colder environment of space, ice does not have enough thermal energy to form crystals.

For the study, published in the journal Science, the research team used a process called ball milling, vigorously shaking ordinary ice together with steel balls in a jar cooled to-200 degrees Centigrade.

Rogue Putin is the biggest risk of 2023. Here are the other 9, explained by global political expert Ian Bremmer.

Read more of Eurasia Group’s top risks for 2023 ► https://www.eurasiagroup.net/issues/top-risks-2023

Today’s world is facing large-scale problems, from wars to water shortages to a looming global recession. It’s not easy to accurately conceptualize the risks posed by these issues. This is especially true when people on social media or in the news inaccurately overblow certain problems and discount others, or when problems become so emotionally or politically charged that it seems impossible to work toward a solution.

That’s one reason why the Eurasia Group publishes a detailed analysis of the top risks facing our world each year. As political scientist Ian Bremmer explains, the top risks for 2023 include water stress, inflation shockwaves, and the uncertain future of a “rogue Russia.”

Bremmer is the founder of Eurasia Group, an organization that for 25 years has been using political science to help investors and corporate decision-makers better understand how politics impact risks and opportunities in foreign markets.

0:00 What is the global risk report?