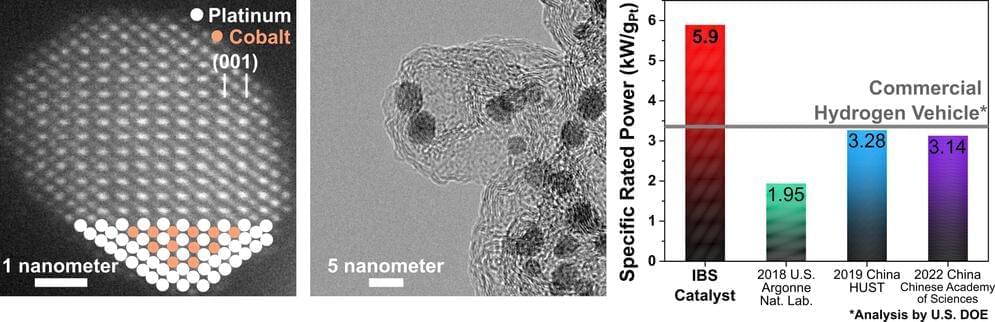

A fuel cell is an electric power generator that is capable of producing electricity from hydrogen gas while discharging only water as a waste product. It is hoped that this highly efficient clean energy system will play a key role in the adoption of the hydrogen economy, replacing the combustion engines and batteries in automobiles and trucks, as well as power plants.

However, the cost of platinum, which can be up to ~30,000 USD per kg, has been a major limitation, making fuel cell catalysts prohibitively expensive. The production methods of highly-performing catalysts have also been complicated and largely limited. Accordingly, the development of a facile and scalable production method for platinum-based fuel cell catalysts is an urgent challenge, together with enhancing catalytic performance and stability while using a minimum amount of platinum.

To tackle this issue, a research team led by Prof. Sung Yung-Eun and Prof. Hyeon Taeghwan at the Center for Nanoparticle Research (CNR) within the Institute for Basic Science (IBS), South Korea has discovered a novel method for the production of nanocatalysts.