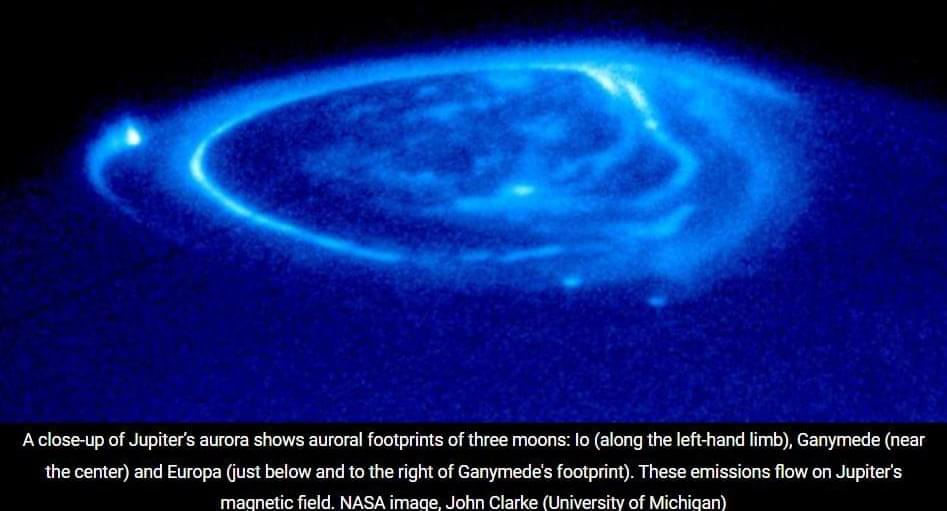

New discoveries about Jupiter could lead to a better understanding of Earth’s own space environment and influence a long-running scientific debate about the solar system’s largest planet. “By exploring a larger space such as Jupiter, we can better understand the fundamental physics governing Earth’s magnetosphere and thereby improve our space weather forecasting,” said Peter Delamere, a professor at the UAF Geophysical Institute and the UAF College of Natural Science and Mathematics.

“We are one big space weather event from losing communication satellites, our power grid assets, or both,” he said.

Space weather refers to disturbances in the Earth’s magnetosphere caused by interactions between the solar wind and the Earth’s magnetic field. These are generally associated with solar storms and the sun’s coronal mass ejections, which can lead to magnetic fluctuations and disruptions in power grids, pipelines and communication systems.