For several years, Professor George Hanna from Imperial College London has been directing work toward the development of a test that can detect cancers of the esophagus and stomach by measuring the levels of five chemicals in a patient’s breath. These chemicals are butyric, pentanoic and hexanoic acids, butanal, and decanal, which previous research has identified as pointers to the presence of stomach or esophageal cancer.

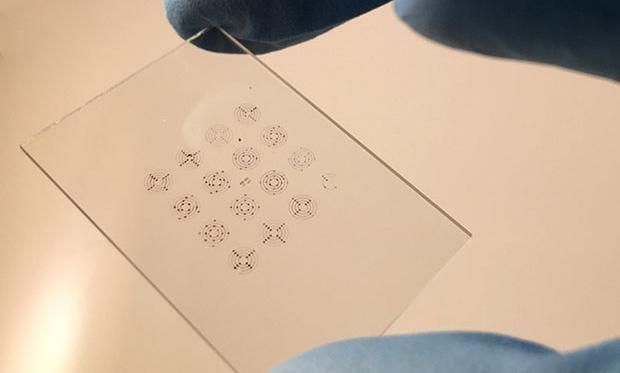

In 2015, Professor Hanna announced the results of the first clinical study analyzing the breath samples of 210 patients. The patents exhaled into a breathalyzer-like device, which used a selected ion flow tube mass spectrometer to detect the presence of any of the five aforementioned chemicals in the breath sample. The 2015 study achieved a 90 percent accuracy rate in correctly identifying the two cancers, and a recently completed, broader study has also proven successful.

The new study collected samples from 335 people across four London hospitals. Around half of the group had been diagnosed with stomach or esophageal cancer and the other half had shown no evidence of cancer after having an endoscopy. After analyzing all the samples, the new breath test achieved an 85 percent accuracy rate, correctly identifying those both with and without cancer.