The loss of pollinators, such as bees, is a huge challenge for global biodiversity and affects humanity by causing problems in food production. At Tampere University, researchers have now developed the first passively flying robot equipped with artificial muscle. Could this artificial fairy be utilized in pollination?

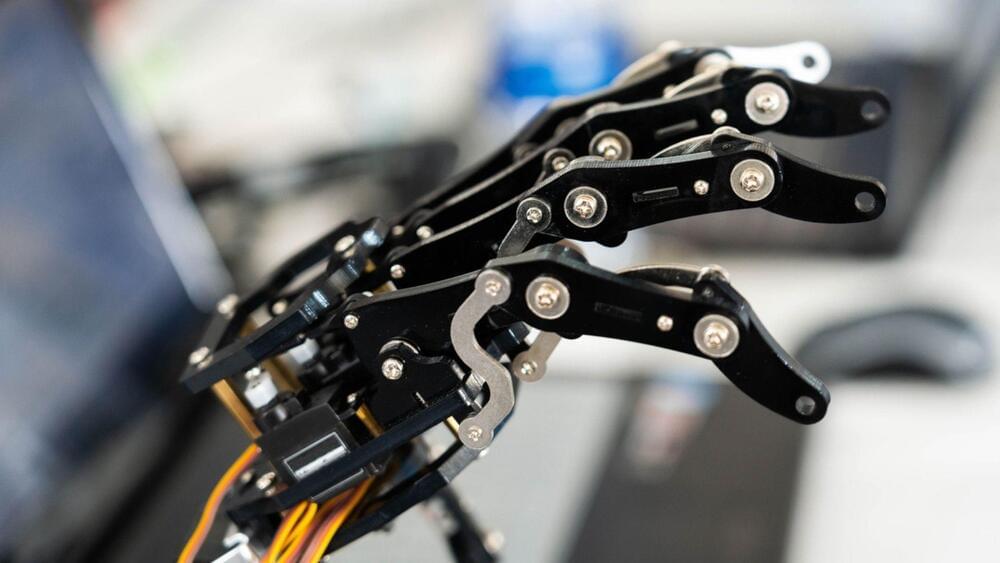

The development of stimuli-responsive polymers has brought about a wealth of material-related opportunities for next-generation small-scale, wirelessly controlled soft-bodied robots. For some time now, engineers have known how to use these materials to make small robots that can walk, swim and jump. So far, no one has been able to make them fly.

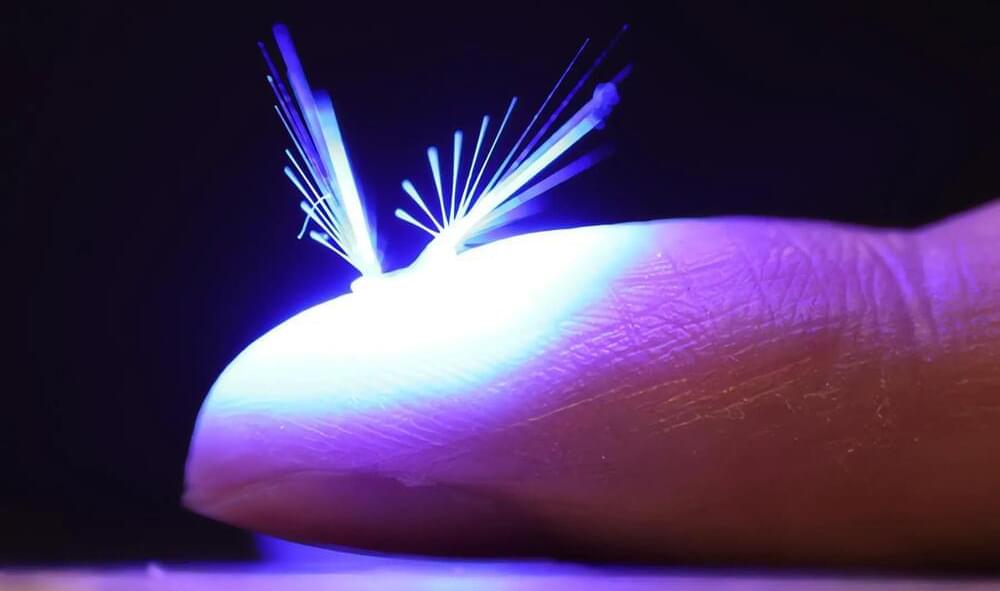

Researchers of the Light Robots group at Tampere University are now researching how to make smart material fly. Hao Zeng, Academy Research Fellow and the group leader, and Jianfeng Yang, a doctoral researcher, have come up with a new design for their project called FAIRY – Flying Aero-robots based on Light Responsive Materials Assembly. They have developed a polymer-assembly robot that flies by wind and is controlled by light.