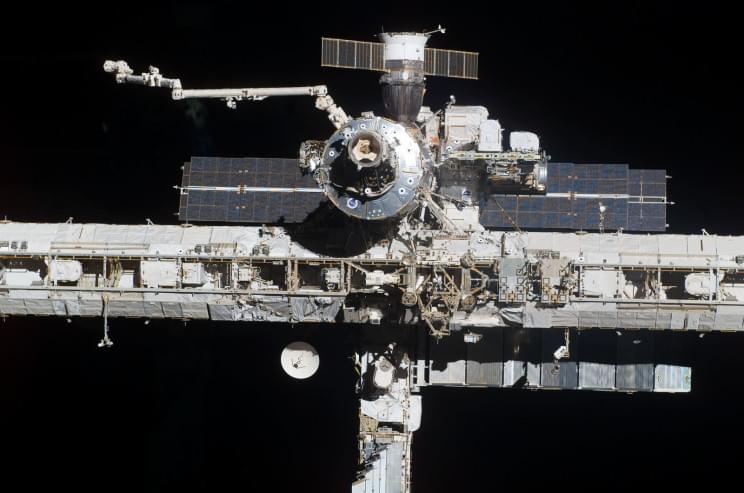

Happy birthday, ISS.

The first components of the International Space Station (ISS) were launched on November 20, 1998, roughly 12 years after the first Soviet MIR-2 module was launched and a full 25 years after Skylab.

The ISS took 10 years and more than 30 missions to assemble. It is the result of unprecedented scientific and engineering collaboration among five space agencies representing 21 countries: NASA (United States of America), Roscosmos (Russia), JAXA (Japan), CSA (Canada), and ESA (16 EU countries and the UK).

With fully-equipped laboratories and advanced life support systems powered by solar arrays, the ISS has space for up to seven crew members to live and work, conducting many kinds of research in low Earth orbit.