OpenAI’s cofounders, including Sam Altman, said in a blog post that there needed to be a proactive approach to managing AI’s potential harms.

In two new studies, North Carolina State University researchers have designed and tested a series of textile fibers that can change shape and generate force like a muscle. In the first study, published in Actuators, the researchers focused on the materials’ influence on artificial muscles’ strength and contraction length. The findings could help researchers tailor the fibers for different applications.

In the second, proof-of-concept study published in Biomimetics, the researchers tested their fibers as scaffolds for live cells. Their findings suggest the fibers—known as “fiber robots”—could potentially be used to develop 3D models of living, moving systems in the human body.

“We found that our fiber robot is a very suitable scaffold for the cells, and we can alter the frequency and contraction ratio to create a more suitable environment for cells,” said Muh Amdadul Hoque, graduate student in textile engineering, chemistry and science at NC State. “These were proof-of concept studies; ultimately, our goal is to see if we can study these fibers as a scaffold for stem cells, or use them to develop artificial organs in future studies.”

United Airlines and California-based startup Archer Aviation have announced plans to use flying cars to ferry passengers between Chicago’s O’Hare International Airport and a “vertiport” just minutes from downtown.

“I’m pleased that Chicago residents will be among the first in the nation to experience this innovative, convenient form of travel,” said Chicago Mayor Lori E. Lightfoot.

The megacity challenge: With 9.6 million residents, Chicago is the third largest metro area in the US, and experts predict the population is going to exceed 10.6 million people by 2050.

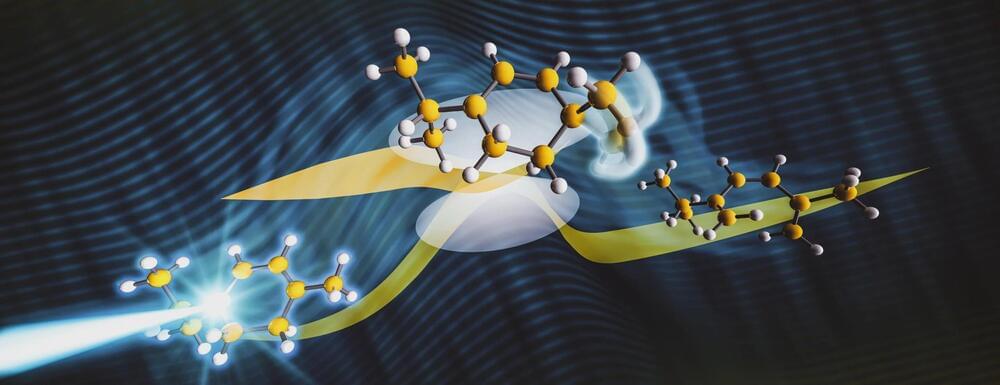

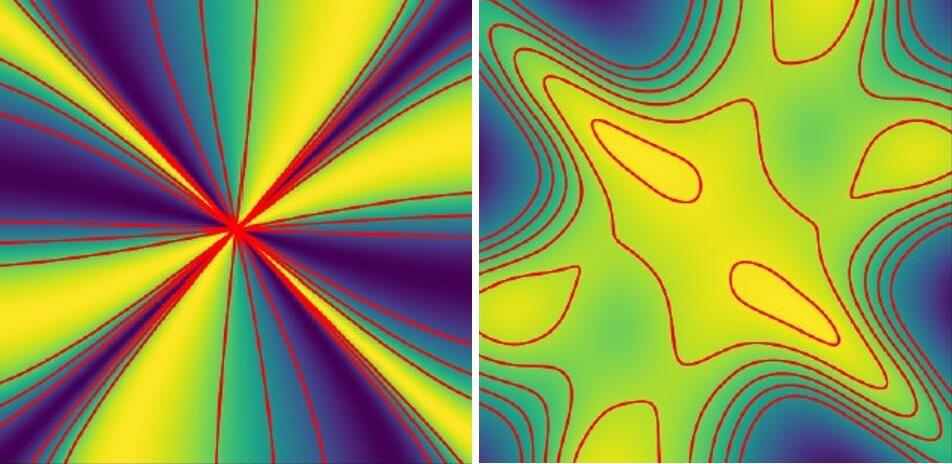

Using a high-speed “electron camera” at the Department of Energy’s SLAC National Accelerator Laboratory and cutting-edge quantum simulations, scientists have directly imaged a photochemical “transition state,” a specific configuration of a molecule’s atoms determining the chemical outcome, during a ring-opening reaction in the molecule α-terpinene. This is the first time that scientists have precisely tracked molecular structure through a photochemical ring-opening reaction, triggered when light energy is absorbed by a substance’s molecules.

The results, published in Nature Communications, could further our understanding of similar reactions with vital roles in chemistry, such as the production of vitamin D in our bodies.

Transition states generally occur in chemical reactions which are triggered not by light but by heat. They are like a point of no return for molecules involved in a chemical reaction: As the molecules gain the energy needed to fuel the reaction, they rearrange themselves into a fleeting configuration before they complete their transformation into new molecules.

You’ve likely seen all the impressive tasks ChatGPT can accomplish, from drafting emails and resumes to writing code and even inventing a new language. But as we wait for AI to make us all obsolete, we might as well enjoy our remaining time in control of the chatbots. One way to do so is by experimenting with all of the fun tricks ChatGPT can perform.

As intelligent and powerful as ChatGPT is, you can also treat it as a toy. Here are some of the best ChatGPT tricks we’ve discovered so far that might not change your life, but will definitely keep you entertained during an especially slow day at work:

If you’re desperate to play a game with someone but can’t actually find a human to play with, ChatGPT is more than capable of standing in. There are a bunch of games that you can play with ChatGPT, including Tic-Tac-Toe, Hangman, and Mad Libs. Just ask ChatGPT to play any of those games, and it will generate the game board and explain the rules.

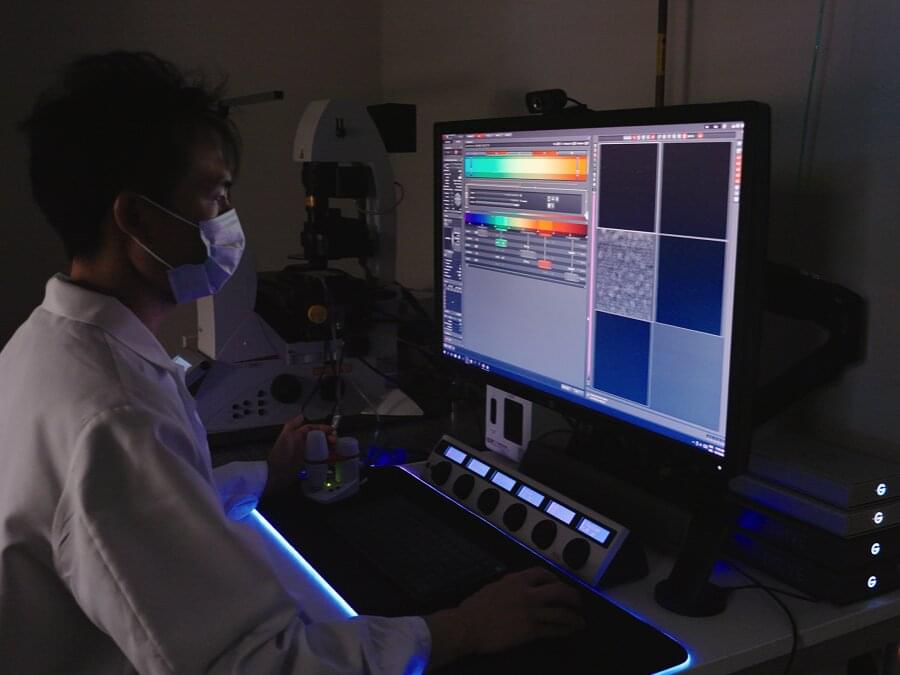

Neural radiance fields (NeRFs) are advanced machine learning techniques that can generate three-dimensional (3D) representations of objects or environments from two-dimensional (2D) images. As these techniques can model complex real-world environments realistically and in detail, they could greatly support robotics research.

Most existing datasets and platforms for training NeRFs, however, are designed to be used offline, as they require the completion of a pose optimization step that significantly delays the creation of photo realistic representations. This has so far prevented most roboticists from using these techniques to test their algorithms on physical robots in real-time.

A research team at Stanford University recently introduced NerfBridge, a new open-source software package for training NeRF algorithms that could ultimately enable their use in online robotics experiments, This package, introduced in a paper pre-published on arXiv, is designed to effectively bridge ROS (the robot operating system), a renowned software library for robotics applications, and Nerfstudio, an open-source library designed to train NeRFs in real-time.

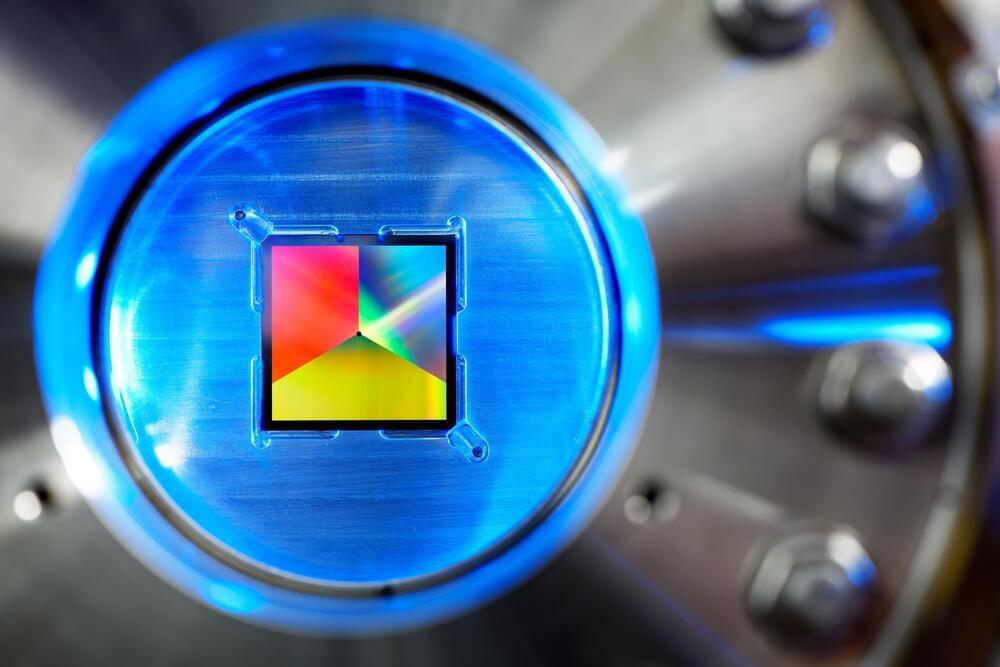

Identifying new sources that produce electrons faster could help to advance the many imaging techniques that rely on electrons. In a recent paper published in Physical Review Letters, a team of researchers at Eindhoven University of Technology demonstrated the scattering of subpicosecond electron bunches from an ultracold electron source.

“Our research group is working to develop the next generation of ultrafast electron sources to push imaging techniques such as ultrafast electron diffraction to the next level,” Tim de Raadt, one of the researchers who carried out the study, told Phys.org.

“The idea of using laser-cooled ultracold gas clouds as an electron source to improve the state-of-the-art in brightness was first introduced in a paper published in 2005. Since then, research efforts have produced multiple versions of such a ultracold electron source, with the most recent one (used in this work) focusing on making the source compact, easy to align and operate, and being more stable, as described in another past paper that also studied the transverse electron beam properties.”

The first protein-based nano-computing agent that functions as a circuit has been created by Penn State researchers. The milestone puts them one step closer to developing next-generation cell-based therapies to treat diseases like diabetes and cancer.

Traditional synthetic biology approaches for cell-based therapies, such as ones that destroy cancer cells or encourage tissue regeneration after injury, rely on the expression or suppression of proteins that produce a desired action within a cell. This approach can take time (for proteins to be expressed and degrade) and cost cellular energy in the process. A team of Penn State College of Medicine and Huck Institutes of the Life Sciences researchers are taking a different approach.

“We’re engineering proteins that directly produce a desired action,” said Nikolay Dokholyan, G. Thomas Passananti Professor and vice chair for research in the Department of Pharmacology. “Our protein-based devices or nano-computing agents respond directly to stimuli (inputs) and then produce a desired action (outputs).”

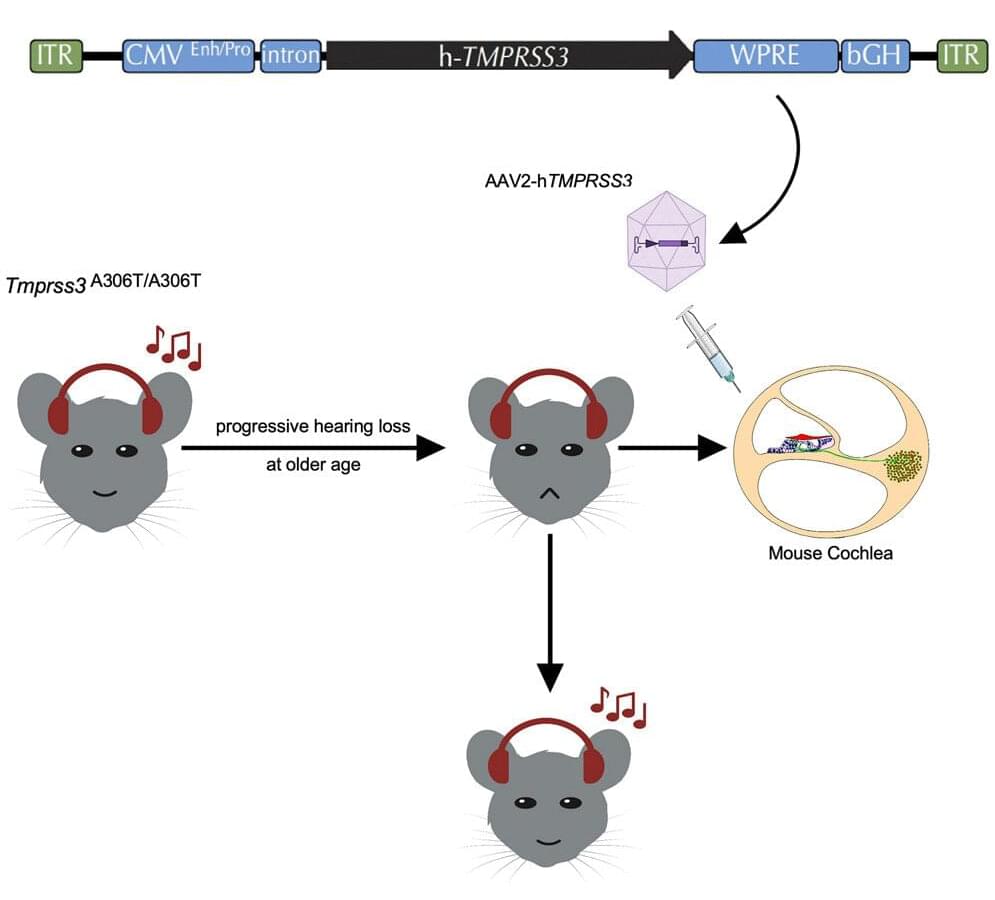

While hearing aids and cochlear implants offer limited relief, no available treatment can reverse or prevent this group of genetic conditions, prompting scientists to evaluate gene therapies for alternative solutions.

One of the most promising tools used in these therapies—adeno associated virus (AAV) vectors—has galvanized the hearing-loss community in recent years.

Excitations in solids can also be represented mathematically as quasiparticles; for example, lattice vibrations that increase with temperature can be well described as phonons. Mathematically, also quasiparticles can be described that have never been observed in a material before. If such “theoretical” quasiparticles have interesting talents, then it is worth taking a closer look. Take fractons, for example.

Fractons are fractions of spin excitations and are not allowed to possess kinetic energy. As a consequence, they are completely stationary and immobile. This makes fractons new candidates for perfectly secure information storage. Especially since they can be moved under special conditions, namely piggyback on another quasiparticle.

“Fractons have emerged from a mathematical extension of quantum electrodynamics, in which electric fields are treated not as vectors but as tensors—completely detached from real materials,” explains Prof. Dr. Johannes Reuther, theoretical physicist at the Freie Universität Berlin and at HZB.