“In adults with diabetes alone—where poor blood flow can lead to quickly worsening wounds that are often very slow or impossible to heal—the lifetime risk of developing a diabetic foot ulcer (DFU), the most common diabetes-related wound, is 20–35 percent and this number is rising with increased longevity and medical complexity of people with diabetes,” stated lead author, Yen-Zhen Lu, PhD, an investigator at ARMI.

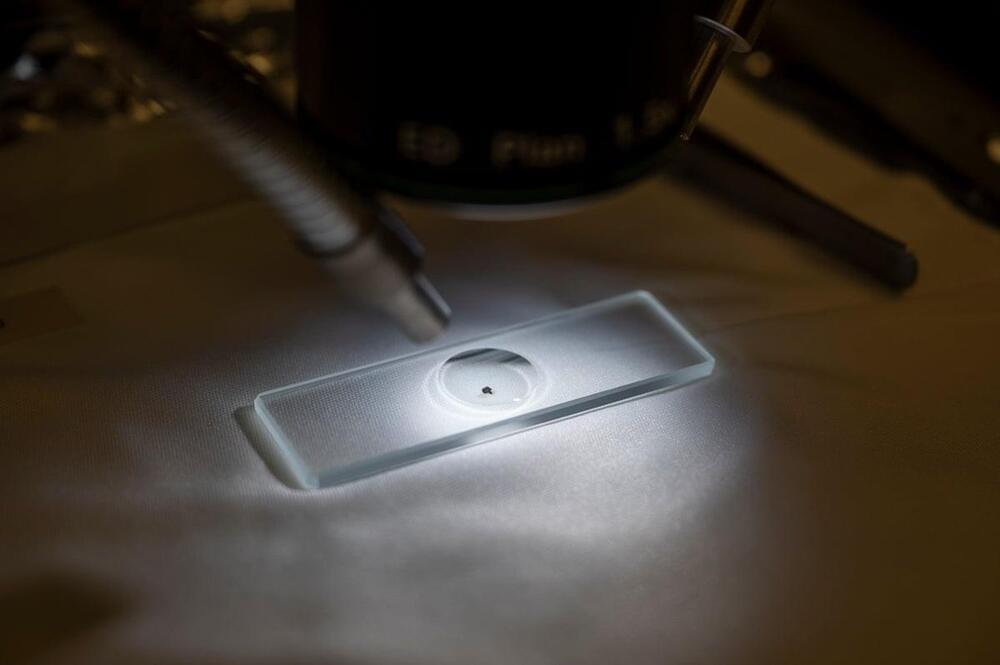

Nociceptors— neurons that sense pain, tissue damage, and inflammation, among other functions— respond to wounds by producing a neuropeptide called calcitonin gene-related peptide (CGRP). “Nociceptor endings grow into injured skin and muscle tissues and signal to immune cells through the neuropeptide CGRP during the healing process,” the authors wrote. Immune cell response in neutrophils, monocytes, and macrophages are modified to encourage active repair in the region.

Individuals with diseases like diabetes or elderly people have reduced production of CGRP, leading to poor, inefficient, or incomplete wound healing. The new study explores the impact of CGRP alone by introducing it into diabetic mice as well as mice without nociceptors. “Delivery of an engineered version of CGRP accelerated wound healing and promoted muscle regeneration,” the authors wrote. “Remarkably, this neuropeptide acts on immune cells to control them, facilitating tissue healing after injury,” added co-author Mikaël Martino, PhD, associate professor, ARMI.