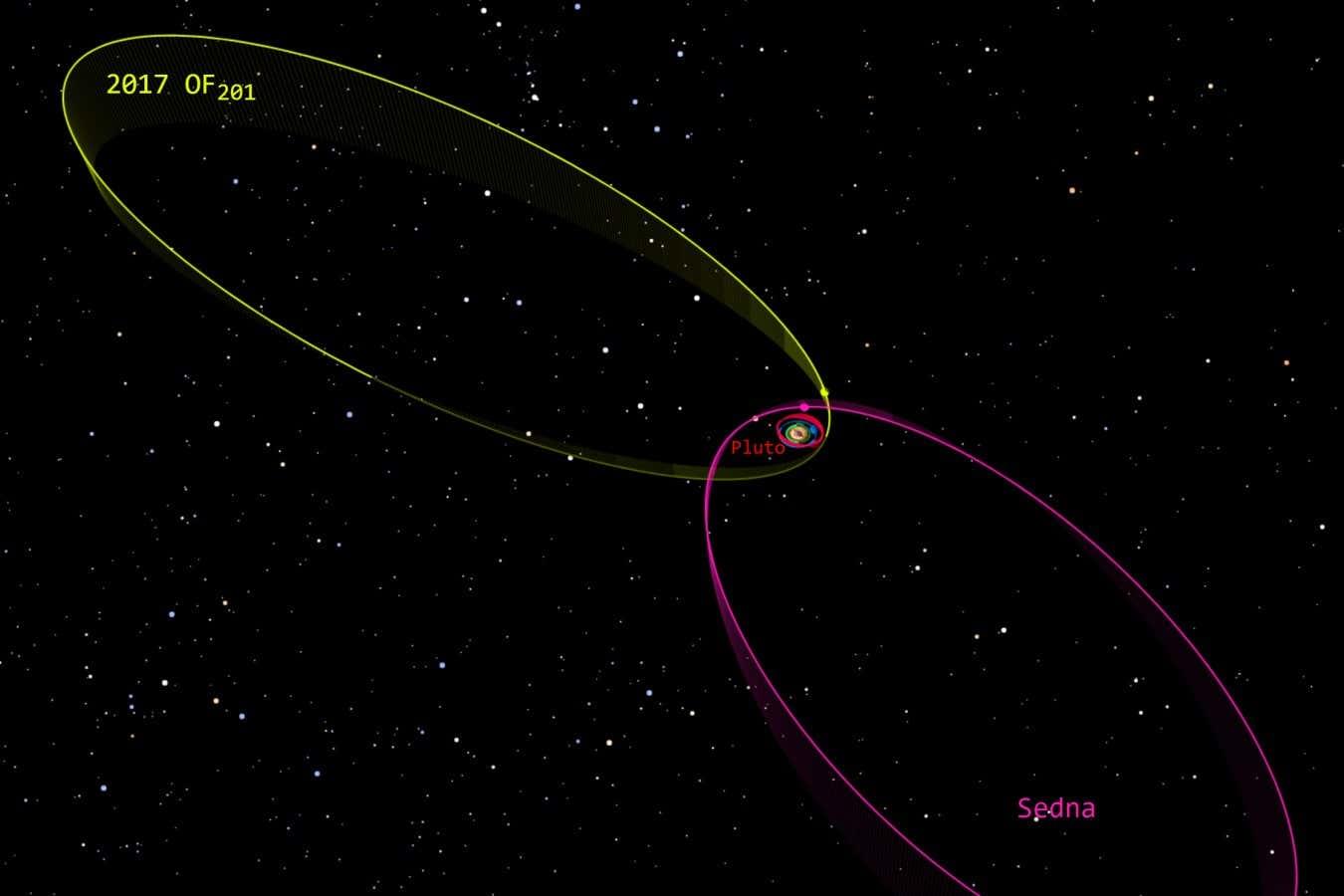

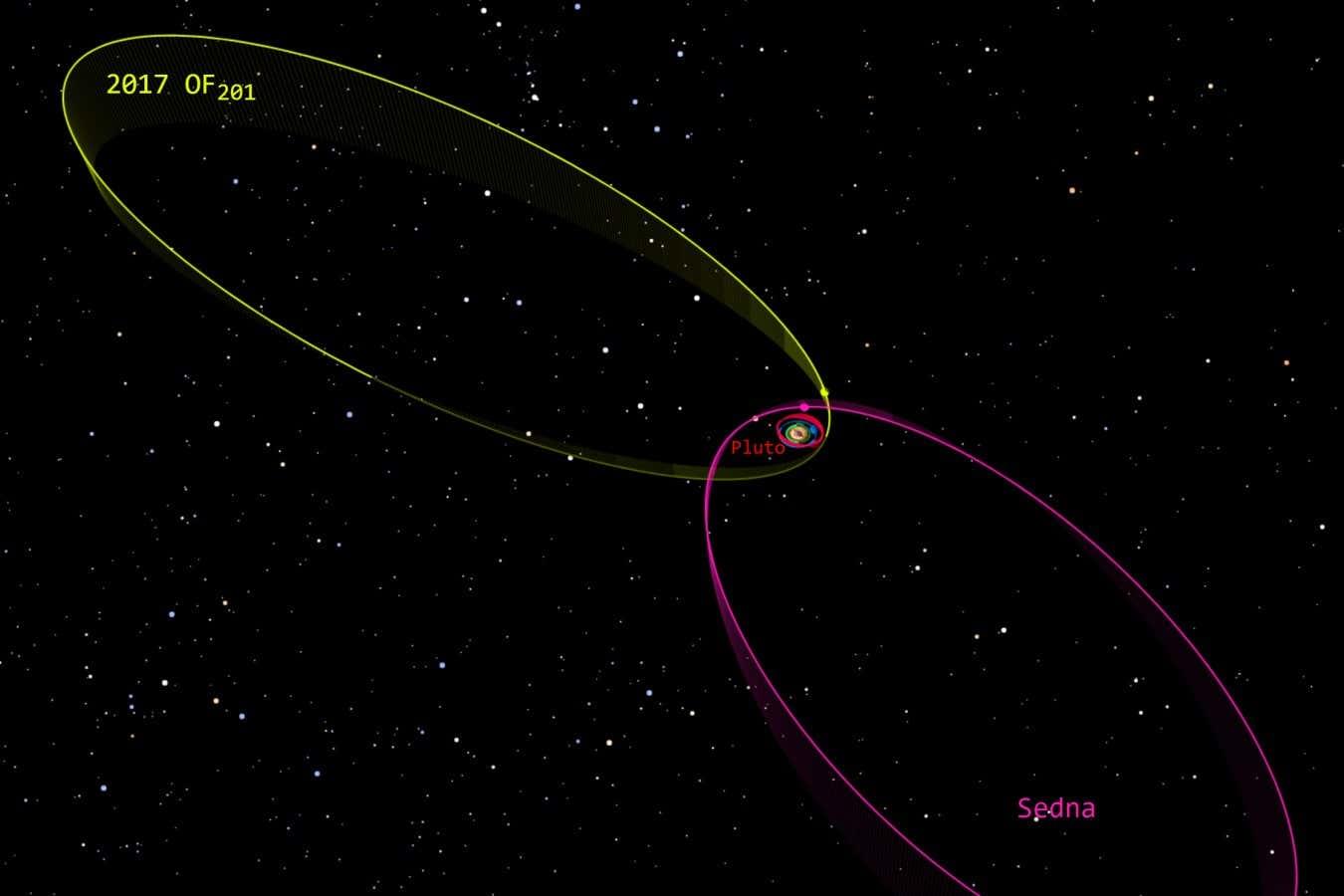

The unusual orbit of a possible dwarf planet, known as 2017 OF201, makes it less likely that our solar system contains a hidden ninth “Planet X”

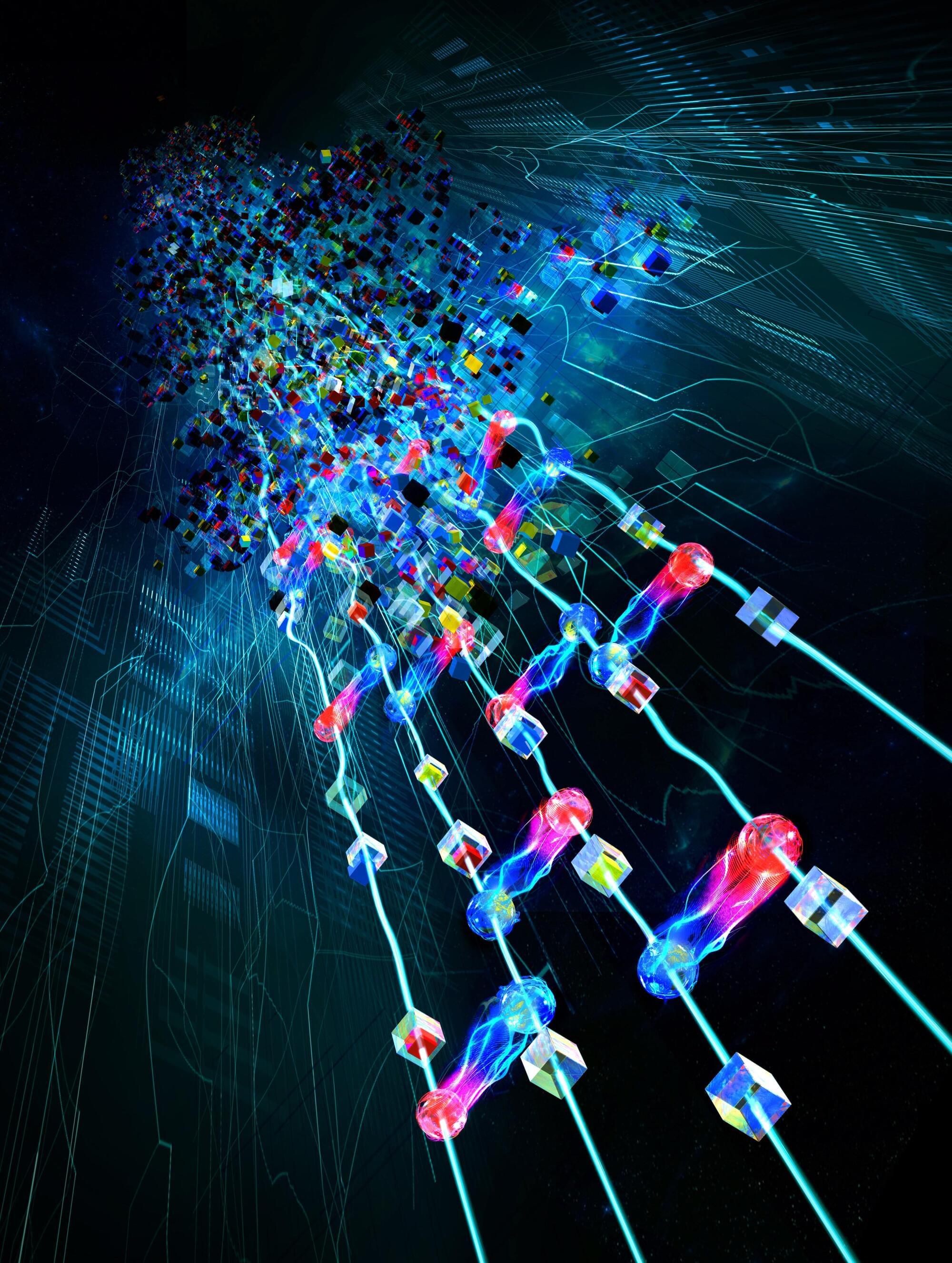

Researchers from the University of Innsbruck have unveiled a novel method to prepare quantum operations on a given quantum computer, using a machine learning generative model to find the appropriate sequence of quantum gates to execute a quantum operation.

The study, recently published in Nature Machine Intelligence, marks a significant step forward in realizing the full extent of quantum computing.

Generative models like diffusion models are one of the most important recent developments in machine learning (ML), with models such as Stable Diffusion and DALL·E revolutionizing the field of image generation. These models are able to produce high quality images based on text description.

Likened by its creators to an “ornate layered cake,” the Tor Alva has been completed in Switzerland. Hailed as the world’s tallest 3D-printed building, this remarkable structure rises to an impressive height of 30 m (98.5 ft).

Tor Alva (aka White Tower) is located in the small alpine village of Mulegns that’s currently home to just 11 people. It was created by researchers at ETH Zurich, in collaboration with cultural foundation Fundaziun Origen, to show off the capabilities of cutting-edge 3D-printing techniques.

Architect Michael Hansmeyer and ETH Professor of Digital Building Technologies Benjamin Dillenburger designed its actual form, which consists of an intricate structure of 32 white concrete columns that rise over four floors and taper before fanning out to top out with a dome. The interior, meanwhile, has a capacity for 32 visitors and includes stairs on each floor, with a performance space at the top.

Anthropic CEO Dario Amodei believes today’s AI models hallucinate, or make things up and present them as if they’re true, at a lower rate than humans do, he said during a press briefing at Anthropic’s first developer event, Code with Claude, in San Francisco on Thursday.

Amodei said all this in the midst of a larger point he was making: that AI hallucinations are not a limitation on Anthropic’s path to AGI — AI systems with human-level intelligence or better.

“It really depends how you measure it, but I suspect that AI models probably hallucinate less than humans, but they hallucinate in more surprising ways,” Amodei said, responding to TechCrunch’s question.

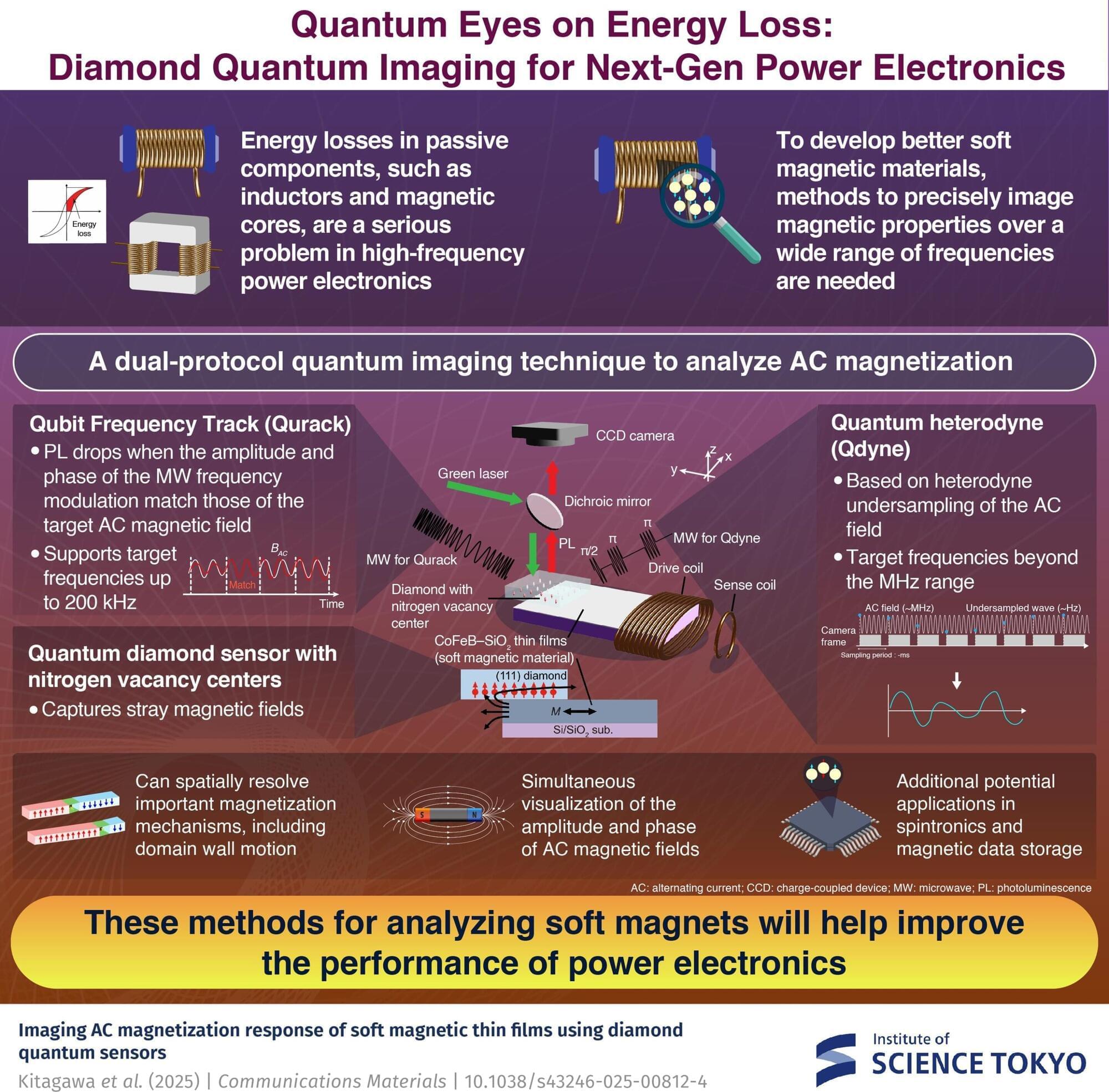

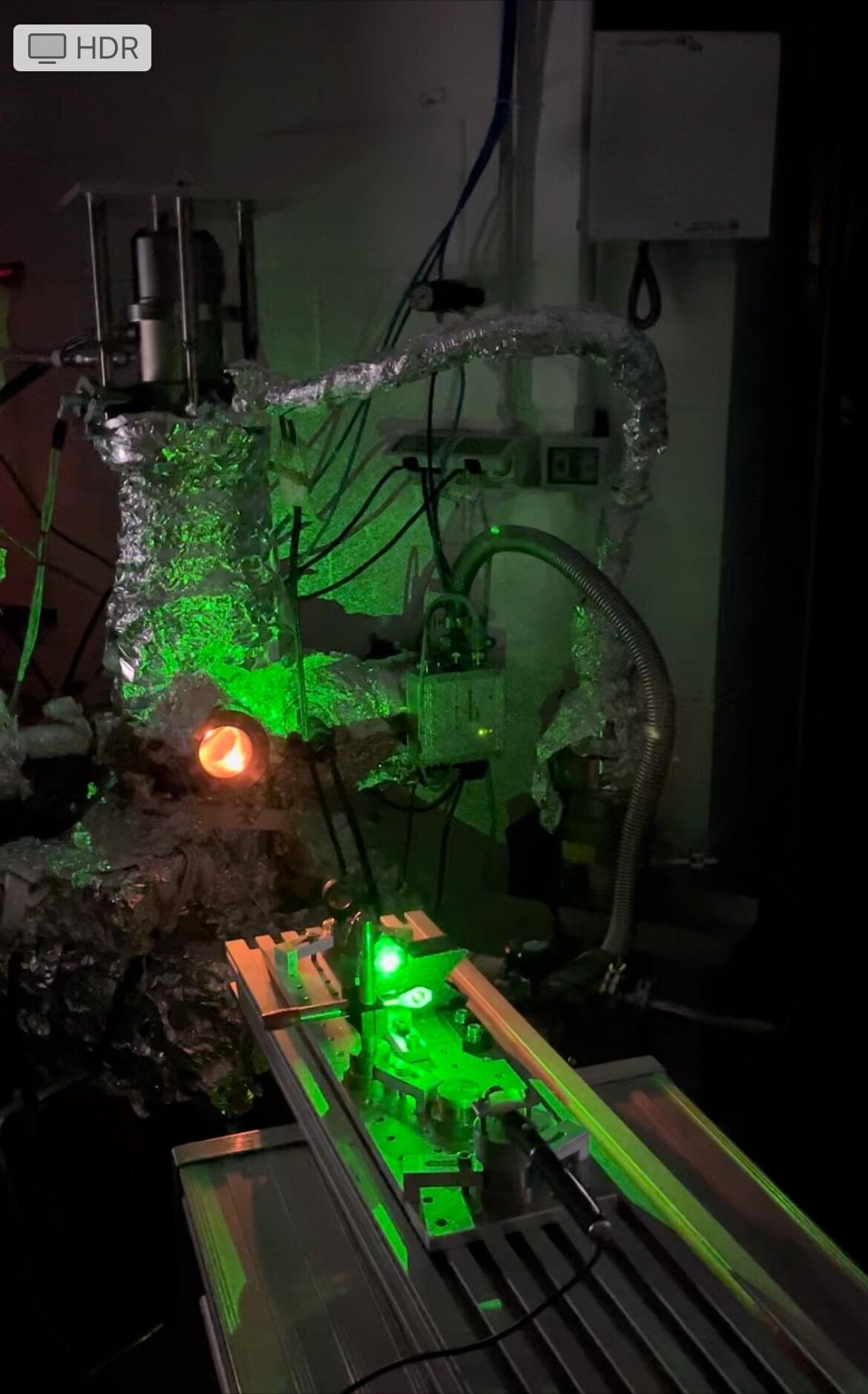

Improving energy conversion efficiency in power electronics is vital for a sustainable society, with wide-bandgap semiconductors like GaN and SiC power devices offering advantages due to their high-frequency capabilities. However, energy losses in passive components at high frequencies hinder efficiency and miniaturization. This underscores the need for advanced soft magnetic materials with lower energy losses.

In a study published in Communications Materials, a research team led by Professor Mutsuko Hatano from the School of Engineering, Institute of Science, Tokyo, Japan, has developed a novel method for analyzing such losses by simultaneously imaging the amplitude and phase of alternating current (AC) stray fields, which are key to understanding hysteresis losses.

Using a diamond quantum sensor with nitrogen-vacancy (NV) centers and developing two protocols—qubit frequency tracking (Qurack) for kHz and quantum heterodyne (Qdyne) imaging for MHz frequencies—they realized wide-range AC magnetic field imaging. This study was carried out in collaboration with Harvard University and Hitachi, Ltd.

In that paper for the SETI Institute, Kershenbaum and colleagues concluded that animal communication research is the closest we are likely to get to studying extraterrestrial signals, until such signals are actually received.

“Many of the challenges facing SETI research are similar to those already addressed in the investigation of animal behavior, and the evolutionary origins of human language,” they wrote. “Indeed, the evolution of language on Earth may in fact have been driven and constrained by similar principles to those operating on life on other planets.”

The researchers have proposed the establishment of a large cross-species database of communicative signals, made available to all SETI and animal behavior researchers.

Watch THIS Next: https://youtu.be/ijQRVEJezWI

Are you really sure that we are alone in the universe? Imagine that somewhere out there, billions of years ago, a highly advanced civilization existed—and we have no idea about it. Or are we perhaps the first? The first to carry technology, culture, and consciousness into space?

Tip me: https://www.subscribestar.com/dave-cullen/tip.

Follow me on X: https://twitter.com/DaveCullenShow.

Subscribestar: https://www.subscribestar.com/dave-cullen.

Source articles: https://www.techtarget.com/searchcontentmanagement/answer/Is…opyrighted.

Follow me on Bitchute: https://www.bitchute.com/channel/hybM74uIHJKg/

KEEP UP ON SOCIAL MEDIA:

https://gab.com/DaveCullen.

Minds.com: https://www.minds.com/davecullen.

Subscribe on Odysee: https://odysee.com/@TheDaveCullenShow:7

Perovskite solar cells are among the most promising candidates for the next generation of photovoltaics: lightweight, flexible, and potentially very low-cost. However, their tendency to degrade under sunlight and heat has so far limited widespread adoption. Now, a new study published in Joule presents an innovative and scalable strategy to overcome this key limitation.

A research team led by the École Polytechnique Fédérale de Lausanne (EPFL), in collaboration with the University of Applied Sciences and Arts of Western Switzerland (HES-SO) and the Politecnico di Milano, has developed a bulk passivation technique that involves adding the molecule TEMPO (2,2,6,6-tetramethylpiperidine-1-oxyl) to the perovskite film and applying a brief infrared heating pulse lasting just half a second.

This approach enables the repair of near-invisible crystalline defects inside the material, boosting solar cell efficiency beyond 20% and maintaining that performance for several months under operating conditions. Using positron annihilation spectroscopy—a method involving antimatter particles that probe atomic-scale defects—the researchers confirmed a significant reduction in vacancy-type defects.