Jul 19, 2016

Scientists develop way to upsize nanostructures into light, flexible 3D printed materials

Posted by Shailesh Prasad in categories: 3D printing, energy, engineering, nanotechnology

For years, scientists and engineers have synthesized materials at the nanoscale level to take advantage of their mechanical, optical, and energy properties, but efforts to scale these materials to larger sizes have resulted in diminished performance and structural integrity.

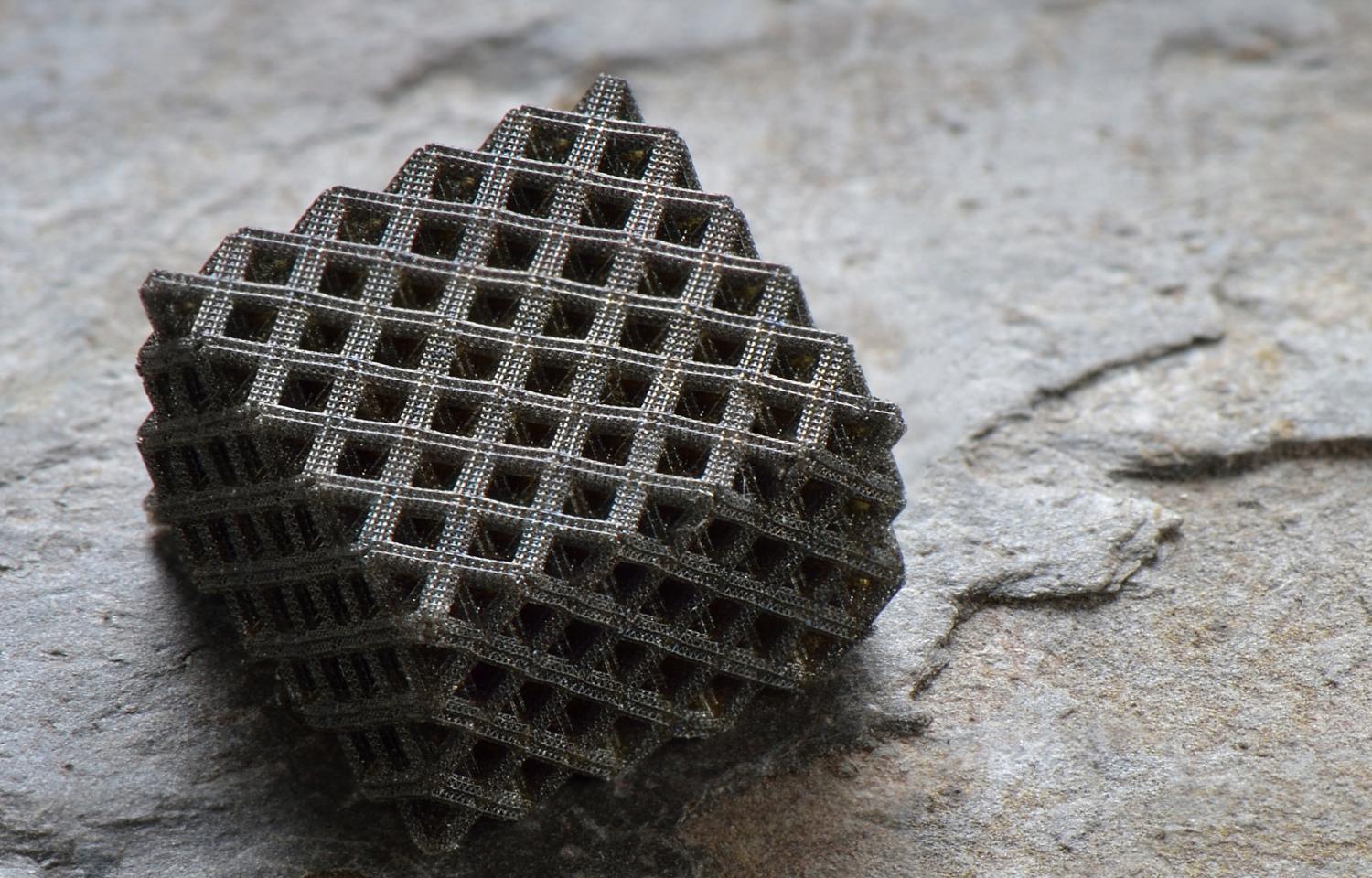

Now, researchers led by Xiaoyu “Rayne” Zheng, an assistant professor of mechanical engineering at Virginia Tech have published a study in the journal Nature Materials that describes a new process to create lightweight, strong and super elastic 3D printed metallic nanostructured materials with unprecedented scalability, a full seven orders of magnitude control of arbitrary 3D architectures.

Strikingly, these multiscale metallic materials have displayed super elasticity because of their designed hierarchical 3D architectural arrangement and nanoscale hollow tubes, resulting in more than a 400 percent increase of tensile elasticity over conventional lightweight metals and ceramic foams.