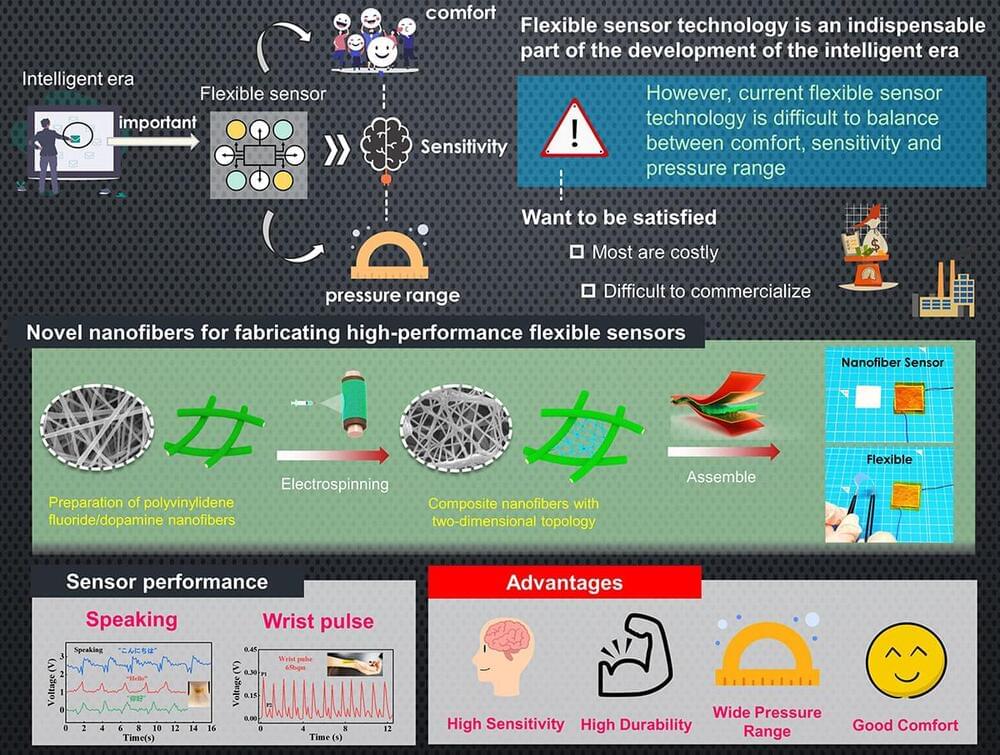

Today’s athletes are always on the lookout for new techniques and equipment to help them train more effectively. Modern coaches and sports trainers use intelligent data monitoring through videos and wearable sensors to help enhance athletic conditioning. However, traditional video analysis and wearable sensor technologies often fall short when tasked with producing a comprehensive picture of an athlete’s performance.

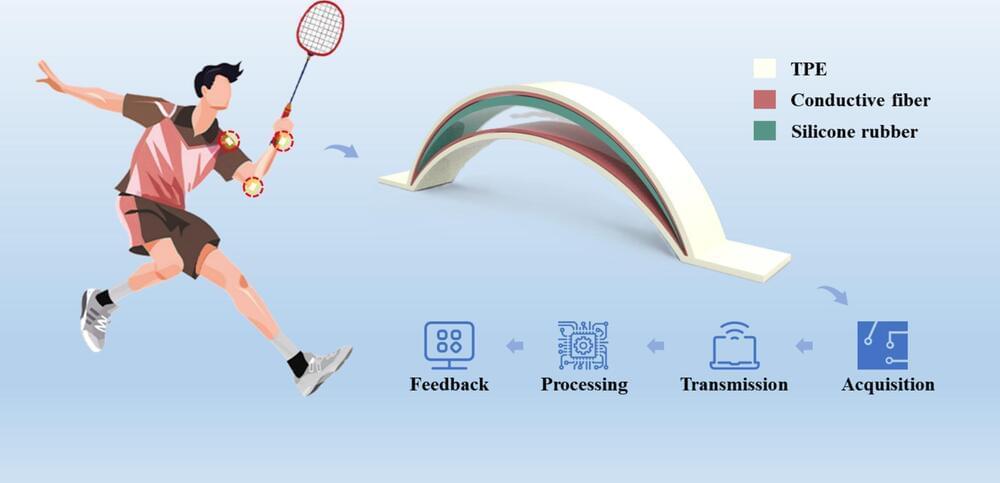

Researchers from Lyuliang University have developed a low-cost, flexible, and customizable sensor for badminton players that overcomes current monitoring constraints. The work is published in APL Materials.

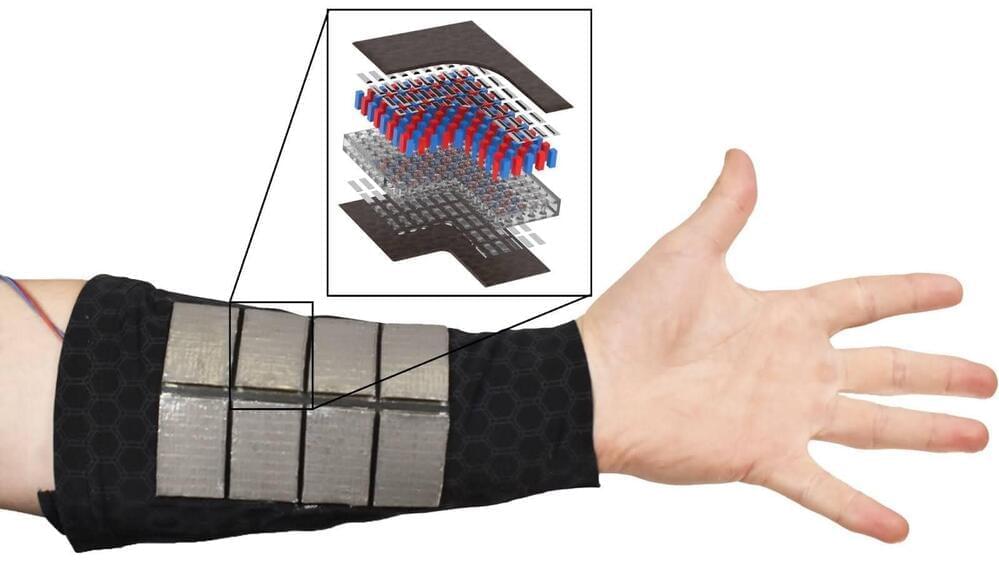

Badminton is known for its many technical movements and the dynamic speed and precision required to play successfully. Monitoring the postures, footwork, arm swings, and muscle strength shown by badminton players is limited by video shooting angles and the discomfort of rigid wearable sensors.