StandardAero will build and help test engines for the Overture supersonic airliner, which Boom Supersonic hopes to have in the air by 2029.

We’re using AI and Google Maps driving trends to optimize traffic light patterns and improve traffic flow. Stop-and-go traffic in urban areas causes 29 times more emissions than on open roads. Researchers at Google are partnering with cities around the globe, from Rio to Jakarta. So far, local governments have saved fuel and lowered emissions for nearly 30 million car rides every month. Learn more about this research at: https://g.co/research/greenlight.

If you are a city representative or traffic engineer and are interested in joining the waiting list, please complete this form: https://docs.google.com/forms/d/e/1FA…

Tweet with us on X: / google \r.

Follow us on Instagram: / google \r.

Join us on Facebook: / google.

Boom Supersonic has taken another step towards its ambitious goal of reintroducing commercial supersonic air travel by the end of this decade. The Colorado-based company released key updates on Tuesday regarding its flagship Overture aircraft and the Symphony engine that will power the supersonic commercial jet. This comes a month after Boom Supersonic officially inaugurated its state-of-the-art factory located at the Piedmont Triad International Airport in Greensboro, North Carolina. The American company chose the Farnborough International Airshow in the UK to reveal Overture’s cutting-edge flight deck, which is built around technology developed by partner Honeywell.

“As we stand here at Farnborough in 2024, it’s now been two decades since either Boeing or Airbus has launched an all-new airliner programme,” said Chief Executive Blake Scholl. “We’re in danger of going a generation without new airliners. We’ve stopped progressing and, in many ways, we’ve gone backwards. It’s never been more clear that passengers and airlines are not well-served by the duopoly we have today.”

“As we stand here at Farnborough in 2024, it’s now been two decades since either Boeing or Airbus has launched an all-new airliner programme,” said Chief Executive Blake Scholl. “We’re in danger of going a generation without new airliners. We’ve stopped progressing and, in many ways, we’ve gone backwards. It’s never been more clear that passengers and airlines are not well-served by the duopoly we have today.”

According to the information revealed by Boom, Overture’s state-of-the-art flight deck runs on Honeywell’s Anthem avionics suite. Electric vertical takeoff and landing (eVTOL) aircraft manufacturers Lilium and Vertical Aerospace have also gone with the same futuristic system. Boom claims Overture would be the commercial jet to feature dual-force feedback sidesticks, which will give a tactile feel to the pilots of how the aircraft is flying. “Overture’s fly-by-wire system sends artificial feel to the stick, giving the pilot a tactile stick and rudder experience,” Scholl added.

Brighter with Herbert.

Construction has begun on what will be the world’s largest underwater road and rail tunnel connecting Denmark and Germany, as Newsweek reported.

The tunnel, which is a major component of the European Union’s Scandinavian-Mediterranean corridor plan, runs beneath the Fehmarn strait for more than 11 miles and aims to cut travel times between the two countries. A 45-minute ferry ride may soon be reduced to a quick seven-minute train commute.

Denmark’s transport minister, Thomas Danielsen, called the project “a milestone in Danish history” at a ceremony celebrating the progress, per the report. He continued, “With the Fehmarnbelt tunnel, we get a fantastic and cross-border infrastructure project.”

Silicon Valley will make oil, nuclear, natural gas, coal, electric utilities, and conventional gas cars obsolete by 2030, leading to the greatest explosion in wealth in history by 2050 Questions to inspire discussion What industries will become obsolete by 2030? —Oil, nuclear, natural gas, coal, electric utilities, a.

Brighter with Herbert.

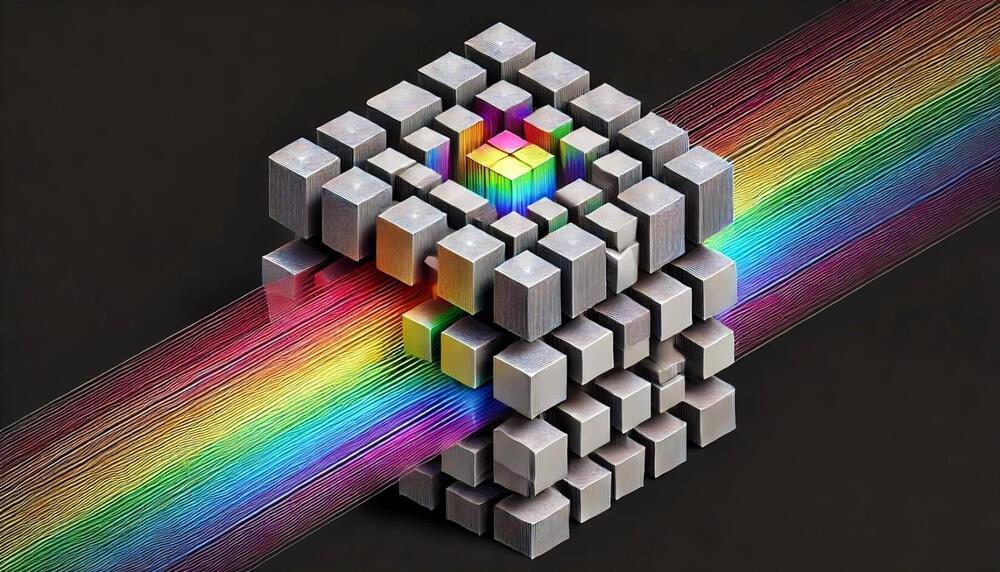

QPI is a powerful technique that reveals variations in optical path length caused by weakly scattering samples, enabling the generation of high-contrast images of transparent specimens. Traditional 3D QPI methods, while effective, are limited by the need for multiple illumination angles and extensive digital post-processing for 3D image reconstruction, which can be time-consuming and computationally intensive.

In this innovative study, the research team developed a wavelength-multiplexed diffractive optical processor capable of all-optically transforming phase distributions of multiple 2D objects at various axial positions into intensity patterns, each encoded at a unique wavelength channel.

This design allows for the capture of quantitative phase images of input objects located at different axial planes using an intensity-only image sensor, eliminating the need for digital phase recovery algorithms.