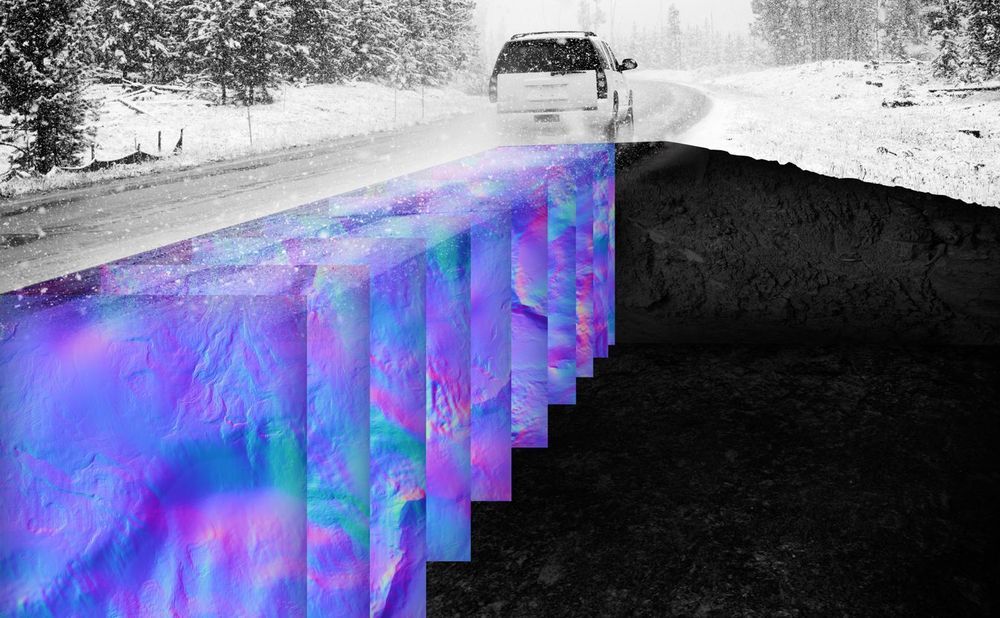

A digital map of rocks, cavities, and utility pipes underground creates a unique signature. Cars can follow it, at speed, in snow, and be within 2 inches of the road center, says WaveSense.

How do you make “environmentally friendly cars” by destroying the environment. This is really uncool. “What would Greta Do?” Environment activists had managed to halt the felling of the trees two days ago, arguing that Tesla’s Gigafactory would affect local wildlife and water supply. However Tesla is said to plant 3 trees for every one it cuts down. Is that good for the wildlife in the forest and the water table?

A high court in Berlin has allowed Tesla to continue clearing a 92 hectare forest for its massive Gigafactory. The court rejected pleas from environment activists and said that its decision was final.

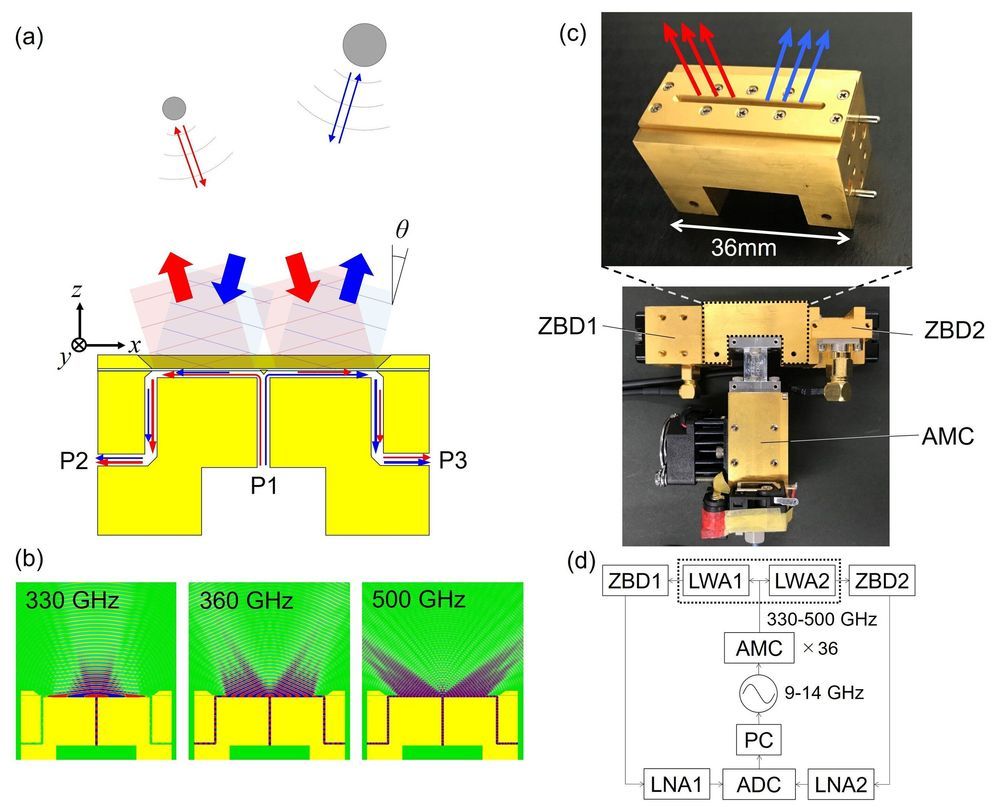

Researchers at Keio University and the National Institute of Information and Communications Technology (NICT) in Japan have recently introduced a new design for a terahertz wave radar based on a technique known as leaky-wave coherence tomography. Their paper, published in Nature Electronics, could help to solve some of the limitations of existing wave radar.

The use of radar, particularly millimeter-wave radar, has increased significantly over the past few years, particularly in the development of smart and self-driving vehicles. The distance and angular resolutions of radar are typically limited by their bandwidth and wavelength, respectively.

Terahertz waves, which have higher frequencies and shorter wavelengths than millimeter waves, allow for the development of radar systems with a smaller footprint and higher resolution. As wavelengths become shorter, however, the attenuation resulting from wave diffraction rapidly increases.

Tesla vehicles are now confirmed to be used in Elon Musk’s Boring Company Loop project to create an electric people mover at Las Vegas’ massive convention center.

You can watch them break through the first tunnel in real time.

Last year, we reported on the Boring Company announcing a new proposed “Loop” system of tunnels for approval in Las Vegas.

3D-printing innovations in recent years have brought a sea change in the fabrication of everything from automobile parts to human bio-tissues.

VICE’s Krishna Andavolu delves into the cutting-edge research behind what’s being called the next industrial revolution, meeting the scientists and entrepreneurs pushing the boundaries of manufacturing, material science, and even space exploration.

Check out VICE News for more: http://vicenews.com

Follow VICE News here:

Facebook: https://www.facebook.com/vicenews

Twitter: https://twitter.com/vicenews

Tumblr: http://vicenews.tumblr.com/

Instagram: http://instagram.com/vicenews

More videos from the VICE network: https://www.fb.com/vicevideo

#VICEonHBO

Cadillac is fully aware it needs to continue launching new vehicles that are not only relevant for the times but also offer something new. That something is — big surprise — electrification. At the moment, GM’s luxury brand does not sell an EV and its only hybrid model, the Cadillac CT6 Hybrid, is about to be discontinued. Eventually, the just-revealed 2021 Cadillac Escalade will likely offer a plug-in hybrid variant and, perhaps, an all-electric one as well. Thing is, Cadillac can’t wait that long for an Escalade EV, but it turns out an alternative is coming very soon.

GM President Mark Reuss announced last week at the automaker’s Capital Markets Day presentation the brand’s first-ever EV will debut this April. And yes, it will be a crossover, a fact that was announced a year ago at the Detroit Auto Show. Oddly, Cadillac did not preview this vehicle with a concept in the Motor City.

NASA Wallops Flight Facility is scheduled to launch a rocket tonight that will be visible to the DMV as it climbs into the sunset sky.

The facility hopes to launch the 13th Northrop Grumman resupply mission to the International Space Station (ISS) at 5:39 p.m. near sunset. The Cygnus cargo ship (spacecraft) is the S.S. Robert H. Lawrence, named for the first ever African American selected as an astronaut.

The launch and mission will be carried live by NASA.