Circa 2017

Today, 15th October 2017, marks the 20th anniversary of the Thrust SSC team setting the World Land Speed Record of 763.035mph — making it the first and only car to reach speeds faster than the speed of the sound.

Circa 2017

Today, 15th October 2017, marks the 20th anniversary of the Thrust SSC team setting the World Land Speed Record of 763.035mph — making it the first and only car to reach speeds faster than the speed of the sound.

2016 VW Action at Santa Pod Raceway. The FireForce 3 Jet car is officially the fastest jet car in the world over the 1/4 mile, having run a 5.79 @ 336mph before!! It is powered by a Pratt & Whitney J60 engine from a Sikorsky Skycrane helicopter, with 5500lbs of thrust, converting to over 10,000hp. Nice video of it still running in the 5’s with a 5.95 but opening the chutes early to cross the line at 224mph.

Real life version of the GTA Vigilante

Please like the videos, subscribe, check out my facebook page and contact me if you are looking for a video of your vehicle. I may just have one smile

The Float is a concept car by Yunchen Chai. It won the design competition hosted by Renault and Central Saint Martins. The participants of the competition had to design a car that emphasized electric power, autonomous driving, and connected technology.

This car uses Meglev technology, is non-directional, and a magnetic belt to attach multiple pods. The Float would even come with an app. This could be the future of car design.

FACEBOOK: https://www.facebook.com/mashable/

TWITTER: https://twitter.com/mashable

INSTAGRAM: https://www.instagram.com/mashable/

Circa 2015

Audi may just be reaching the point of producing electric vehicles, but an Ohio-based industrial designer has an idea for where they should go after mastering that craft.

Kevin Clarridge of Columbus, Ohio, has shared a few sketches of his design for a wheel-free Audi sedan straight out of the 22nd century. A post to his Facebook page Oct. 8 shared a few images, while his Behance profile shows a few more color options for this concept.

A new $32,000 electric camper is getting some hype this week, but we are highly skeptical about the vehicle. Is it a scam?

Electric Brands, a Germany-based startup, has been taking reservations and investments for what it calls the eBussy, a modular electric vehicle platform that can be configured in different vehicles, including an electric camper.

Several media outlets have been reporting on the project this week, resulting in thousands of reservations for the vehicle.

Chinese electric startup Kandi announces that its small K27 electric car has been approved for California roads and it is going to cost only $7,999 in the state after incentives.

Several Chinese automakers are currently looking to expand outside of China, and that’s especially true of electric vehicle makers.

Even foreign automakers, like Volvo and BMW, are now producing electric vehicles in China and exporting them globally. The Chinese-made Polestar 2 is due later this year. BMW is also looking at bringing Chinese made EVs to the US.

BMW is launching the iX3 electric SUV in Europe with the vehicle arriving at dealerships from China.

Here we share a close look photo gallery of the new electric vehicle.

When unveiling the BMW iX3 concept vehicle in 2018, the German automaker said that it’s going to be the first electric vehicle based on its fifth-generation electric powertrain technology, which is designed to enable longer electric range.

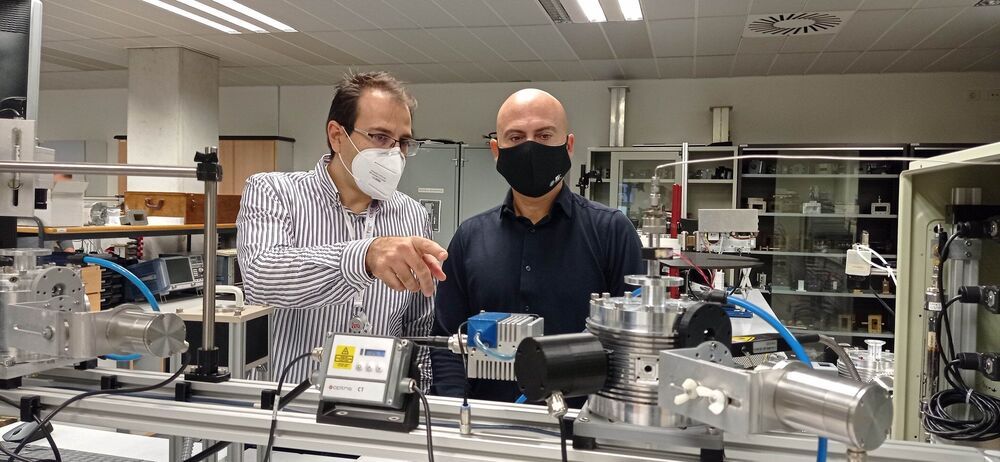

A team of researchers from the Polytechnic University of Valencia and the Spanish National Research Council (CSIC) has discovered a new method that makes it possible to transform electricity into hydrogen or chemical products solely using microwaves—without cables and without any type of contact with electrodes. This represents a revolution in the field of energy research and a key development for the process of industrial decarbonisation, as well as for the future of the automotive sector and the chemical industry, among many others. The study has been published in the latest edition of Nature Energy, where the discovery is explained.

The technology developed and patented by the UPV and CSIC is based on the phenomenon of the microwave reduction of solid materials. This method makes it possible to carry out electrochemical processes directly without requiring electrodes, which simplifies and significantly cheapens its practical use, as it provides more freedom in the design of the structure of the device and choosing the operation conditions, mainly the temperature. It is a technology with great practical potential, especially for its use in storing energy and producing synthetic fuels and green chemical products. This aspect has significant importance today, as both transportation and industry are immersed in a transition to decarbonise, meaning they have to meet very demanding goals between 2030 and 2040 to decrease the consumption of energy and substances from fossil sources, mainly natural gas and oil, highlights José Manuel Serra, research lecturer of the CSIC at the Chemical Technology Institute.

We’re all too familiar with the work-play balance we strive to juggle in the 21st century. It’s virtually impossible, right? We’re often faced with a long and busy commute to work, using dated public transport or busy highways, only to find ourselves sitting in a dull office all day long. Well Tencent is about to revolutionize the work-play life of 80,000 people in the city of Shenzhen, with a next-century approach!

Following Huawei’s campus-style city, Chinese technology company Tencent, the driving power behind instant messaging apps WeChat and QQ, has made promises to build an entire mini-city off the banks of the Pearl River in Shenzhen, where the company has its headquarters. Both are located in the Guangdong province of Southern China, near the metropolis of Hong Kong.

How Gaming Tech Giant Tencent is building its own futuristic city.