Car owners can save hundreds of dollars by letting utilities decide when to charge their car.

😀

Tesla hasn’t yet shipped the Cybertruck, or the full-size Cyberquad that made a splashy debut at the introduction of its Blade Runner-esque pickup truck, but you can get a mini Cyberquad designed for the kiddos starting in 2–4 weeks if you order one right now from its website.

The Tesla “Cyberquad for Kids” is available to purchase on Tesla’s site for $1,900 — a steep price relative to your average Power Wheels, but the lowest-priced vehicle in Tesla’s existing lineup by far. And the Cyberquad’s materials are a cut above your average battery electric kid car, with a “full steel frame,” along with cushioned seating and fully adjustable suspension.

It may be the cheapest Tesla you can buy, but it’s also the most limited when it comes to range: You’ll get up to around 15 miles on a full charge, which takes five hours, according to the company. It’s also not going to break any land speed records, with a speedometer that tops out at 10 mph (which you can limit to a max of 5 mph for safety, if desired). That’s still plenty fast for a kid’s ride-on vehicle, which is probably why Tesla labels this one as designed for kids at least 8 and up, with a max weight of 150 lbs.

And you won’t need an FAA pilot’s license to fly it either, since Opener’s Blackfly is certified as an ultralight aircraft.

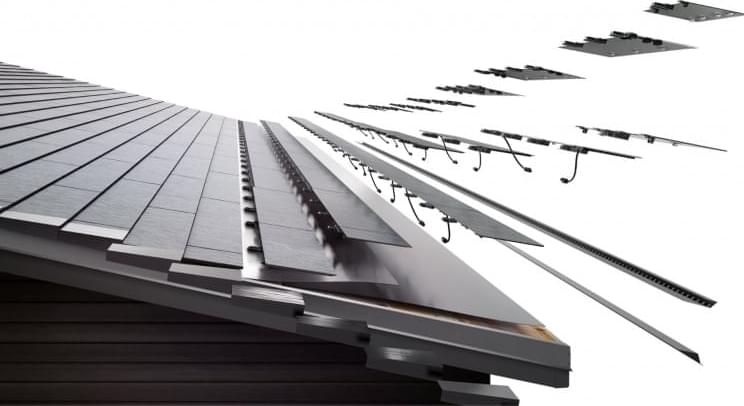

In yet another bid to push forward its solar business, electric vehicle maker Tesla has launched a new solar roof tile that has a higher power output while retaining the dimensions of the old one.

Tesla entered the clean energy business when it acquired SolarCity for $2.6 billion in 2016. It makes switching to solar energy sleeker by replacing regular roof tiles with energy-generating solar roof tiles, instead of having to install bulky solar panels. Tesla offers a 25-year warranty on the tiles and takes end-to-end responsibility for installing the new solar roof.

However, the company has so far struggled to make its product mainstream due to fluctuations in pricing, Electrek reported. With variations across house designs, Tesla has found it difficult to create a streamlined product and even introduced a roof-complexity factor, earlier this year to determine cost estimates.

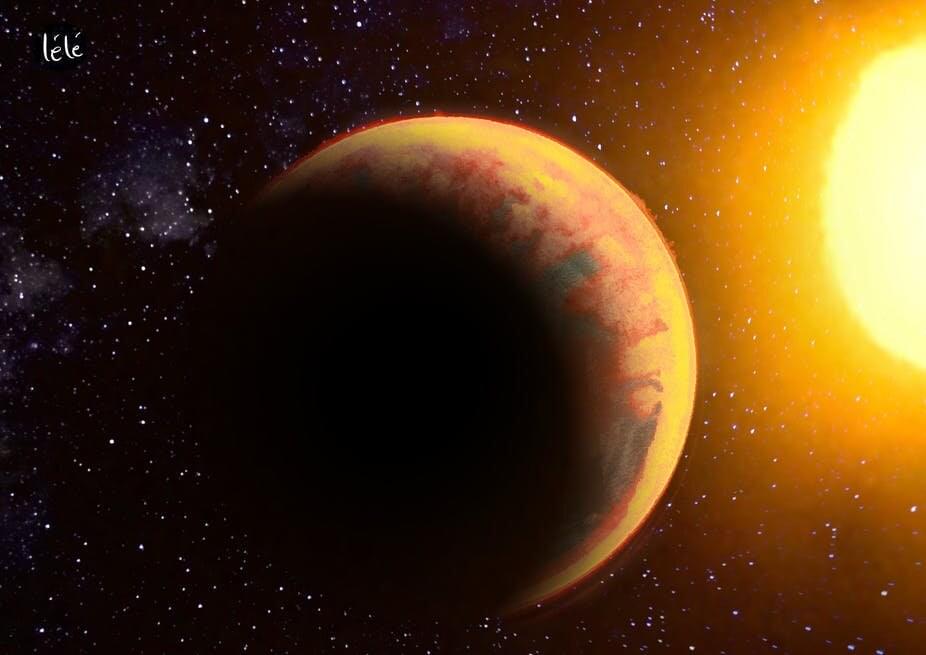

Do you know what the Earth’s atmosphere is made of? You’d probably remember it’s oxygen, and maybe nitrogen. And with a little help from Google you can easily reach a more precise answer: 78% nitrogen, 21% oxygen and 1% Argon gas. However, when it comes to the composition of exo-atmospheres—the atmospheres of planets outside our solar system—the answer is not known. This is a shame, as atmospheres can indicate the nature of planets, and whether they can host life.

As exoplanets are so far away, it has proven extremely difficult to probe their atmospheres. Research suggests that artificial intelligence (AI) may be our best bet to explore them—but only if we can show that these algorithms think in reliable, scientific ways, rather than cheating the system. Now our new paper, published in The Astrophysical Journal, has provided reassuring insight into their mysterious logic.

Astronomers typically exploit the transit method to investigate exoplanets, which involves measuring dips in light from a star as a planet passes in front of it. If an atmosphere is present on the planet, it can absorb a very tiny bit of light, too. By observing this event at different wavelengths—colors of light—the fingerprints of molecules can be seen in the absorbed starlight, forming recognizable patterns in what we call a spectrum. A typical signal produced by the atmosphere of a Jupiter-sized planet only reduces the stellar light by ~0.01% if the star is Sun-like. Earth-sized planets produce 10–100 times lower signals. It’s a bit like spotting the eye color of a cat from an aircraft.

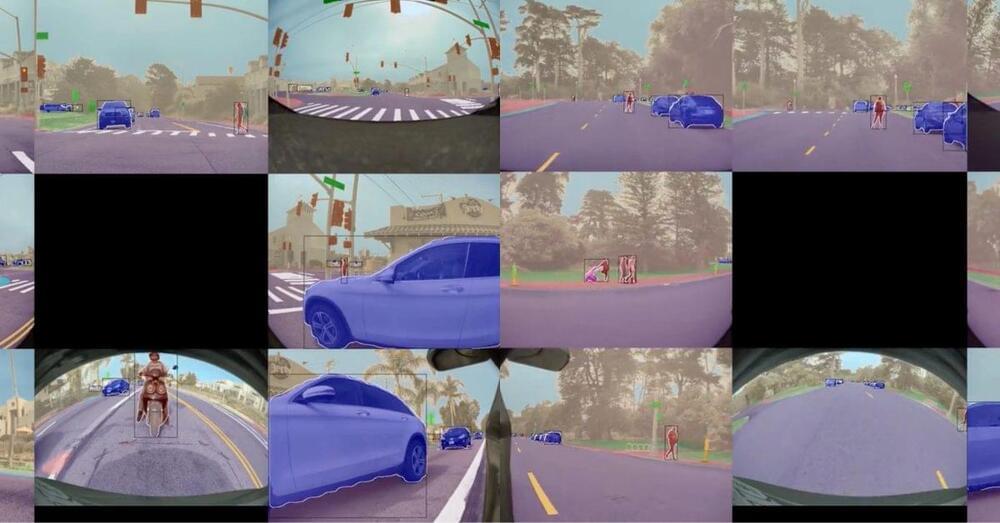

Tesla’s head of AI has released new footage of the automaker’s auto labeling tool for its self-driving effort.

It’s expected to be an important accelerator in improving Tesla’s Full Self-Driving Beta.

Tesla is often said to have a massive lead in self-driving data thanks to having equipped all its cars with sensors early on and collecting real-world data from a fleet that now includes over a million vehicles.

Electrify America announced that it has now deployed over 30 MW of battery capacity using Tesla Powerpacks at over 140 charging stations.

In 2019, Tesla and Electrify America, VW’s electric vehicle charging network, announced that they reached a deal for the former to deploy Powerpacks at more than 100 charging stations operated by the latter.

We have been tracking their progress in deploying those battery systems since it appears to be the largest deployment of energy storage at electric vehicle charging stations.

Solar car can be better.

The cost of electric vehicle battery packs has fallen to $132 per kWh – continuing decades of cost improvements. However, it might go up over the next year as increased material prices are catching up to incremental cost improvements.

Price per kWh is the metric used to track the price of batteries. It can be used to talk about the cost of battery packs or battery cells.

For example, if Tesla were achieving a cost per kWh of $150 for its Model S battery pack, it would mean that the battery pack costs $15,000 since it has a capacity of 100 kWh.

And it’s down for tests this year.

Last month, Pantuo Aviation revealed the PANTALA Concept H, a sleek-looking flying taxi concept that has strong similarities to Lilium’s ducted fan eVTOL aircraft at the same time as featuring some key design differences.

As little was announced in the way of specifications or development progress at the time, we reached out to Pantuo, who sent us information on their new concept via a company spokesperson.

According to Pantuo Aviation’s representative, the all-electric PANTALA Concept H has a range of 155 miles (250 km) and will be able to travel at speeds of over 186 mph (300 km/h). The aircraft uses lithium-ion batteries and features 22 large-diameter electric ducted fans rather than open rotors. Much in the same fashion as Lilium’s seven-seater aircraft, which the German company aims to bring into service by 2024, the PANTALA’s fans provide added redundancy, meaning an enhanced level of safety for passengers. One factor that sets the PANTALA Concept H apart from the Lilium flying taxi, however, is the fact that its entire wing tilts to change from vertical to normal flight mode.

Full Story: