Researchers from university in southern China say their porous material has high mechanical strength and thermal insulation properties.

BMW’s 5 series is set to expand very soon. The automaker is teasing the new BMW i5 M60 Touring, giving us a sneak peek at what we can expect from the high-performance EV.

After teasing an electric 5 series sedan for over six years, BMW finally unveiled the i5 last May. It’s a slightly larger, all-electric take on its predecessor. BMW included its latest software and tech, including OS 8.5.

The i5 is in the middle of the 3 series and larger 7 series in BMW’s lineup. As its second best-selling vehicle, the 5 series has and will continue to play a key role in the brand’s success.

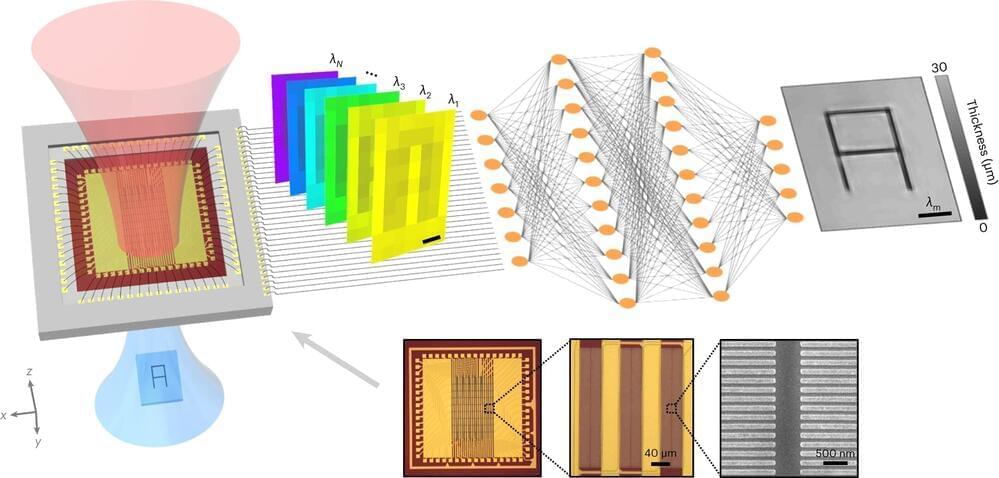

Terahertz waves can penetrate opaque materials and provide unique spectral signatures of various chemicals, but their adoption for real-world applications has been limited by the slow speed, large size, high cost and complexity of terahertz imaging systems. The problem arises from the lack of suitable focal-plane array detectors, components that contain radiation detectors used by the imaging system.

A research team led by Mona Jarrahi, and Aydogan Ozcan, both electrical and computer engineering professors at the UCLA Samueli School of Engineering, has invented a new terahertz focal-plane array to solve this problem.

By eliminating the need for raster scanning, which captures and displays an image point by point, the research team is able to expedite imaging more than 1,000 times faster than current systems. The new array constitutes the first known terahertz imaging system that is fast enough to capture videos and provide real-time, 3D multi-spectral images while maintaining a high signal-to-noise ratio.

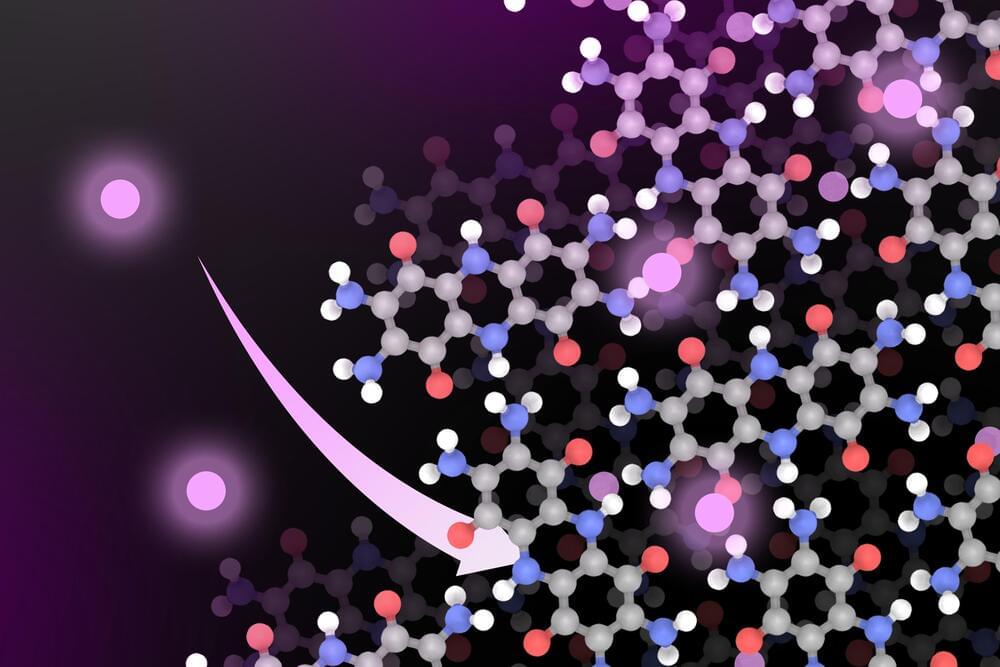

Many electric vehicles are powered by batteries that contain cobalt — a metal that carries high financial, environmental, and social costs.

MIT researchers have now designed a battery material that could offer a more sustainable way to power electric cars. The new lithium-ion battery includes a cathode based on organic materials, instead of cobalt or nickel (another metal often used in lithium-ion batteries).

In a new study, the researchers showed that this material, which could be produced at much lower cost than cobalt-containing batteries, can conduct electricity at similar rates as cobalt batteries. The new battery also has comparable storage capacity and can be charged up faster than cobalt batteries, the researchers report.

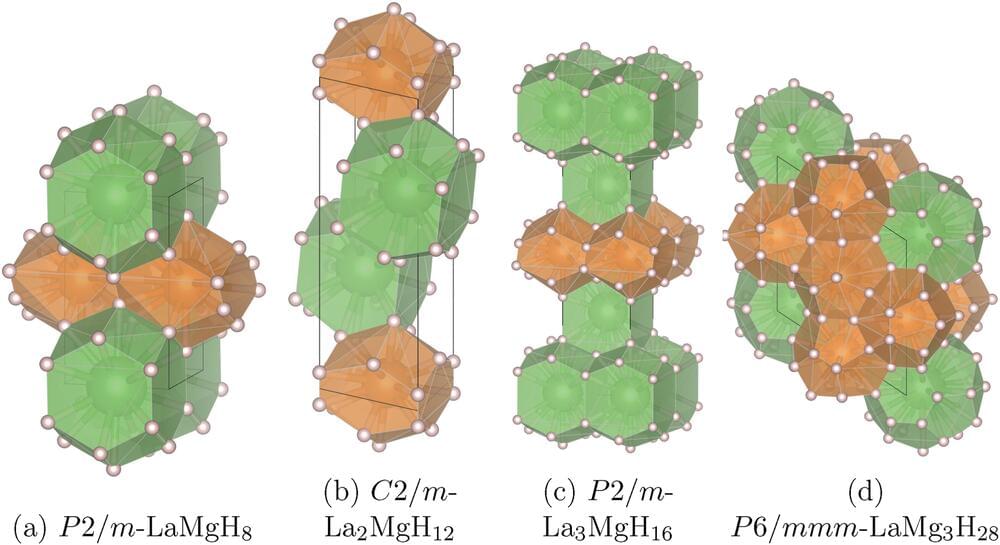

Skoltech researchers and their colleagues from MIPT and China’s Center for High Pressure Science and Technology Advanced Research have computationally explored the stability of the bizarre compounds of hydrogen, lanthanum, and magnesium that exist at very high pressures. In addition to matching the various three-element combinations to the conditions at which they are stable, the team discovered five completely new compounds of hydrogen and either magnesium or lanthanum only.

Published in Materials Today Physics, the study is part of the ongoing search for room-temperature superconductors, the discovery of which would have enormous consequences for power engineering, transportation, computers and more.

“In the previously unexplored system of hydrogen, lanthanum, and magnesium, we find LaMg3H28 to be the ‘warmest’ superconductor. It loses electrical resistance below −109°C, at about 2 million atmospheres—not a record, but not bad at all either,” the study’s principal investigator, Professor Artem R. Oganov of Skoltech, commented.

Airships are essentially rigid, steerable balloons that fly because they’re filled with a lighter-than-air gas. The Hindenburg is probably the most well-known example of an — and also the most-well known example of why filling them with flammable hydrogen is dangerous.

Brin’s plan is to fill hiss with non-flammable helium and then use them to transport tons of cargo hundreds of miles efficiently and cleanly. He also hopes to use them for humanitarian missions, delivering supplies and personnel to places that are hard to access by road.

The Pathfinder-1: In 2015, Brin founded a startup, LTA Research, to help him reach this goal, and the team came up with the Pathfinder-1, a 400-foot-long prototype with electric motors, a carbon-fiber skeleton, and an ultra-light synthetic cover.

BMW wants humanoid robots to build its cars, evidenced by a partnership with a robotics startup that it signed today.

BMW has partnered with Figure in its first partnership since the company was founded two years ago. The German automaker plans to launch a small, controlled launch of humanoid robots in its production facilities, potentially expanding to more units if performance targets are met.

The humanoid robots will initially be launched out of the BMW facility in Spartanburg, South Carolina, which employs 11,000 people.

Using AI and cloud computing, Microsoft was able to identify promising new battery materials for the Department of Energy (DoE) — in a fraction of the time it would usually take.

The challenge: Batteries are an essential part of the clean energy future. We need them to power electric vehicles and to store energy from solar and wind.

Currently, lithium-ion batteries are our best option for both of these uses, but they aren’t ideal. Because lithium is relatively scarce, it’s also expensive, and the metal is often unethically mined using child labor and environmentally destructive processes.

“I think this material could have a big impact because it works really well,” said Dr. Mircea Dincă. “It is already competitive with incumbent technologies, and it can save a lot of the cost and pain and environmental issues related to mining the metals that currently go into batteries.”

Electric vehicles (EVs) have become a household name in the last few years with several companies fighting to compete in the everchanging EV landscape as EV technology continues to improve in cost, efficiency, and the materials used to manufacture the batteries responsible for sustaining this clean energy revolution. While EV batteries have traditionally used cobalt for their battery needs, a recent study published in ACS Central Science discusses how organic cathode materials could be used as a substitute for cobalt for lithium-ion batteries while potentially offering similar levels of storage capacity and charging capabilities, as cobalt has shown to be financially, environmentally, and socially expensive.

“Cobalt batteries can store a lot of energy, and they have all of features that people care about in terms of performance, but they have the issue of not being widely available, and the cost fluctuates broadly with commodity prices,” said Dr. Mircea Dincă, who is a W.M. Keck Professor of Energy at MIT and a co-author on the study.

For their study, the researchers constructed a layered organic cathode comprised of cellulose, rubber, and other Earth-based elements. The team then subjected their organic cathode to a variety of tests, including energy storage, delivery, and charging capabilities. In the end, they found their cathode’s capabilities exceed most cobalt-based cathodes, including a charge-discharge time of 6 minutes. Additionally, while battery cathodes are known for significant wear and tear due to cracking from the flow of lithium ions, the researchers noted that the rubber and cellulose materials helped extend the battery cathode’s lifetime.