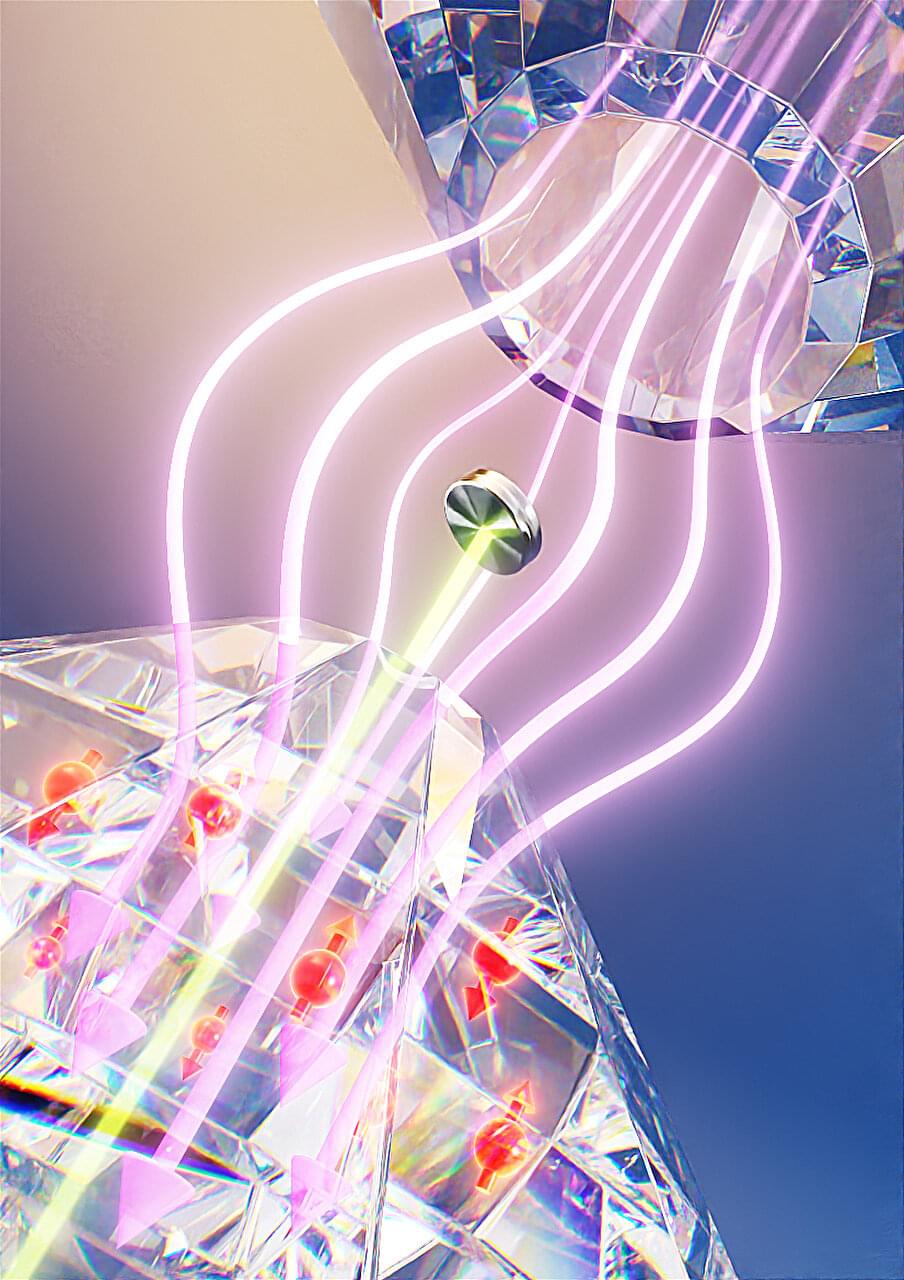

Diamond is known for its outstanding thermal conductivity. This makes the material ideal for cooling electronic components with high power densities, such as those used in processors, semiconductor lasers or electric vehicles. Researchers at Fraunhofer USA, an independent international affiliate of the Fraunhofer-Gesellschaft, have succeeded in developing wafer-thin nanomembranes from synthetic diamonds that can be integrated into electronic components, thereby reducing the local heat load by up to ten times. This helps to improve the road performance and service life of electric cars and significantly reduces battery charging time.

An increase in power density and the resulting higher heat dissipation in electronic components require new materials. Diamond is known for its high thermal conductivity, which is four to five times higher than that of copper. For this reason, it is a particularly interesting material when it comes to cooling power electronics in electric transportation, photovoltaics or storage systems.

Until now, heat sinks made of copper or aluminum plates have increased the heat-emitting surface of components that produce heat, thus preventing damage due to overheating.