A new documentary highlights the challenges overcome by the experimental aircraft, Solar Impulse.

Category: sustainability – Page 506

Tesla (TSLA) receives massive new order of Tesla Semi electric trucks — biggest yet?

Tesla (TSLA) has received a massive new order of Tesla Semi electric trucks from a truck-leasing company.

It might be its biggest order for the Tesla Semi program yet.

When Tesla launched the Tesla Semi in 2017, the automaker used the same reservation model that made it successful with passenger electric vehicles.

Making the First Martians: Living on the Red Planet

There are many options for living on Mars. 3D-printed ice habitats around the poles, building underground, etc. The technology is finally here.

This is part of the reason why the surface is so cold, ranging from −143 in the polar regions during winter and 35 °C (−226 to 95 °F) near the equator during midday in the summer. But because the air is so thin, a person standing on Mars (in the summer and at noon) would experience extreme cold anywhere above their ankles.

And then there’s the radiation, which is roughly 40 times higher than what humans are regularly exposed to here on Earth (worse, when a solar event occurs). There are also massive dust storms that can envelop the entire planet and block out all sunlight. Last, there’s Martian gravity, which is about 37% of what we experience here on Earth.

In short, Mars is cold, dry, irradiated, and the air is thin and unbreathable. But with the right kind of living strategies and technology, living on Mars could be possible. In particular, life on Mars will rely heavily on 3D printing, in-situ resource utilization (ISRU), renewable energy, radiation shielding, and lots of recycling and compost systems.

Audi Electromagnetic Hover Car Concept Design

Circa 2015

Audi may just be reaching the point of producing electric vehicles, but an Ohio-based industrial designer has an idea for where they should go after mastering that craft.

Kevin Clarridge of Columbus, Ohio, has shared a few sketches of his design for a wheel-free Audi sedan straight out of the 22nd century. A post to his Facebook page Oct. 8 shared a few images, while his Behance profile shows a few more color options for this concept.

Reaching for the Moon, Mars and beyond: This is how space exploration can benefit all

The secrets of the solar system can drive economic return for all.

The launch of NASA’s fifth Mars rover marks a new milestone in the era of space exploration. It puts focus on the need for greater collaboration, equity and inclusion among international partners to ensure the sustainable, peaceful and fair use of resources. Guidelines for interacting and norms of behaviour are as essential to ensure success in space as on Earth.

The Artemis Accords: a framework for cooperation

The Artemis Accords, recently announced by NASA, is a framework to encourage international cooperation and ensure a safe, prosperous and sustainable future for all humankind in space. The Accords are bi-lateral agreements between the United States and other nations who wish to collaborate with NASA on the Artemis program, and they build on existing agreements with countries already involved in NASA-led programs such as the International Space Station.

Here’s a new $32,000 electric camper and we are highly skeptical

A new $32,000 electric camper is getting some hype this week, but we are highly skeptical about the vehicle. Is it a scam?

Electric Brands, a Germany-based startup, has been taking reservations and investments for what it calls the eBussy, a modular electric vehicle platform that can be configured in different vehicles, including an electric camper.

Several media outlets have been reporting on the project this week, resulting in thousands of reservations for the vehicle.

Kandi’s small electric car to cost $7,999 in California

Chinese electric startup Kandi announces that its small K27 electric car has been approved for California roads and it is going to cost only $7,999 in the state after incentives.

Several Chinese automakers are currently looking to expand outside of China, and that’s especially true of electric vehicle makers.

Even foreign automakers, like Volvo and BMW, are now producing electric vehicles in China and exporting them globally. The Chinese-made Polestar 2 is due later this year. BMW is also looking at bringing Chinese made EVs to the US.

BMW launches iX3 electric SUV [Gallery]

BMW is launching the iX3 electric SUV in Europe with the vehicle arriving at dealerships from China.

Here we share a close look photo gallery of the new electric vehicle.

When unveiling the BMW iX3 concept vehicle in 2018, the German automaker said that it’s going to be the first electric vehicle based on its fifth-generation electric powertrain technology, which is designed to enable longer electric range.

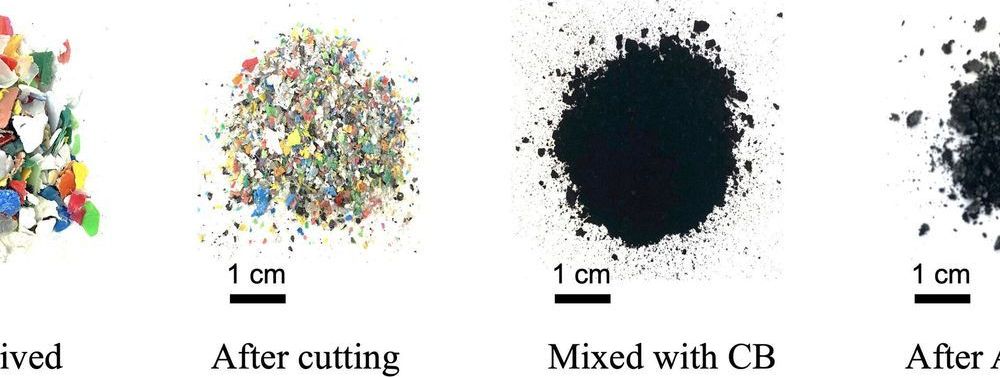

Flash graphene rocks strategy for plastic waste

Plastic waste comes back in black as pristine graphene, thanks to ACDC.

That’s what Rice University scientists call the process they employed to make efficient use of waste plastic that would otherwise add to the planet’s environmental woes. In this instance, the lab of Rice chemist James Tour modified its method to make flash graphene to enhance it for recycling plastic into graphene.

The lab’s study appears in the American Chemical Society journal ACS Nano.