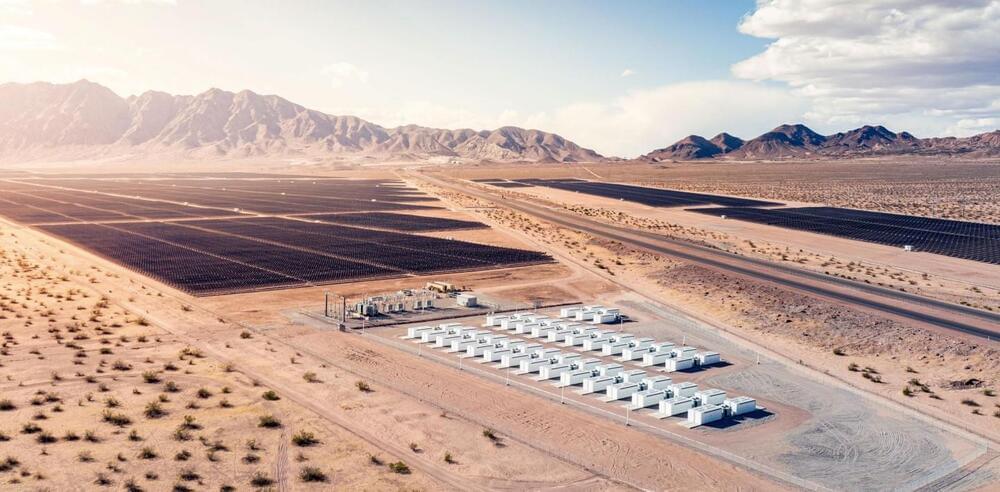

A cellphone-sized device automatically adjusts a home’s power use up or down to save the consumer money and increase the resiliency of the electric grid.

The effects of climate change are pushing electrical grids around the world to their limits. Last year, unprecedented cold weather caused people in Texas to turn up their thermostats, which overwhelmed the power grid and caused days-long power outages. And in California, the power is turned off before there is a high possibility of a fire.

To combat the electric grid’s vulnerabilities and cut down on the use of non-renewable sources of energy, researchers at the Department of Energy’s SLAC National Accelerator Laboratory have developed technology that automatically adjusts a home’s power use up or down in response to fluctuating prices that are established by real-time market demand.