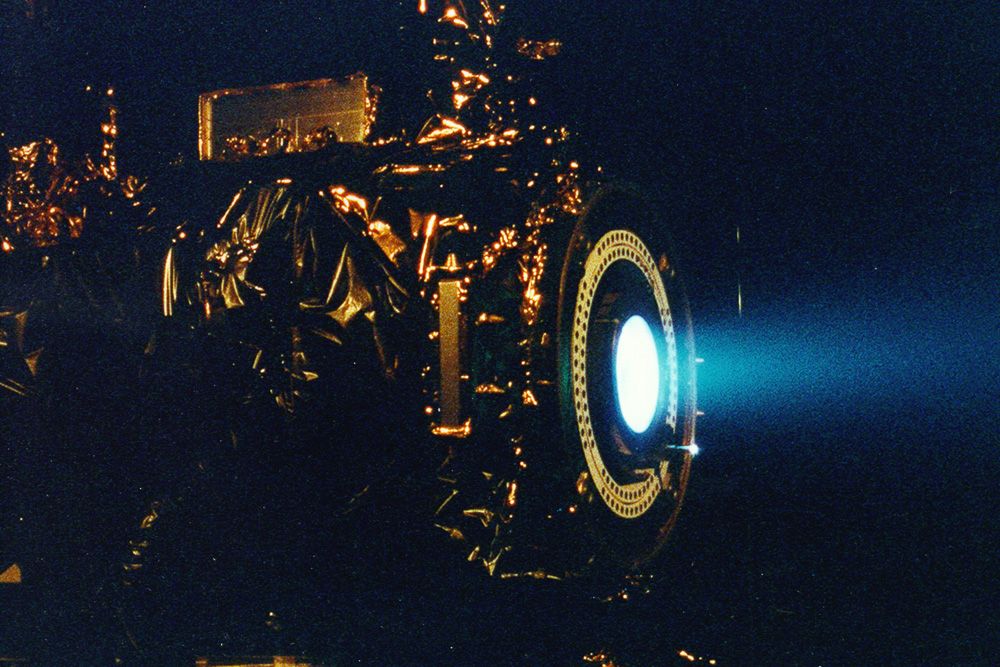

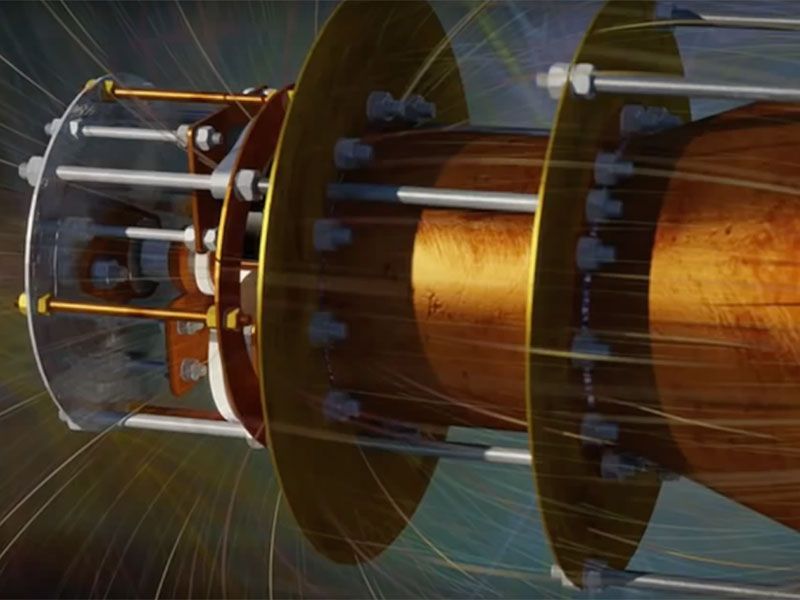

Earlier this month Hacked reported that a draft version of the much expected EmDrive paper by the NASA Eagleworks team, had been leaked. Now, the final version of the paper has been published.

The NASA Eagleworks paper, titled “Measurement of Impulsive Thrust from a Closed Radio-Frequency Cavity in Vacuum,” has been published online as an open access “article in advance” in the American Institute of Aeronautics and Astronautics (AIAA)’s Journal of Propulsion and Power, a prestigious peer-reviewed journal. The paper will appear in the December print issue of the journal.

The final version of the paper is very similar to the leaked draft. In particular, the NASA scientists confirm the promising experimental results: