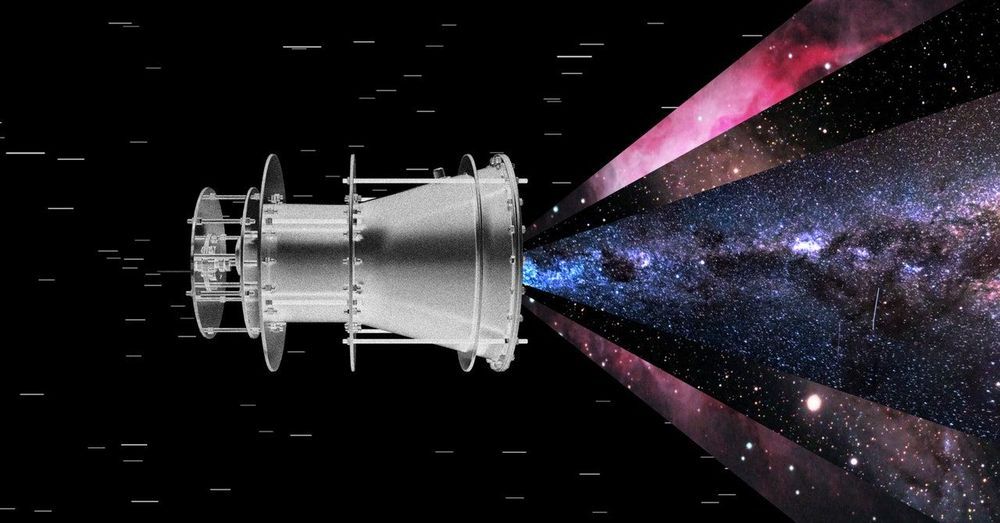

An internal attainability report proposes the organization maybe, or possibly that going through collapsed space is a piece of the NASA interstellar spaceflight menu.

In the report, propelled impetus physicist Harold “Sonny” White clarifies the thoughts of a hypothetical physicist (and companion) Miguel Alcubierre. He at that point portrays an “oddity” in Alcubierre’s work, and how that Catch 22 may be set out to make a working model.

The conversational term “twist drive” has originated from sci-fi, and it alludes to sub-luminal (not exactly the speed of light) head out that complies with Einstein’s hypothesis of general relativity yet at the same time pushes speed to total most extreme that is hypothetically conceivable. In the Star Trek canon, dynamic structures come consistently nearer to a theoretical obstruction—the manner in which genuine researchers keep on slashing ever nearer to supreme zero. In actuality, light speed is the hindrance.

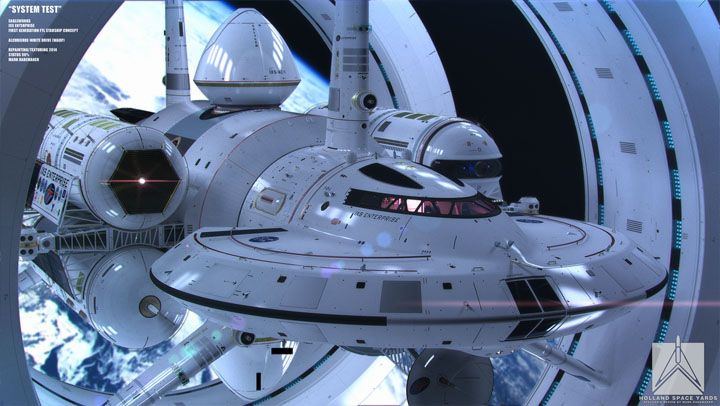

[Image Source:

[Image Source: