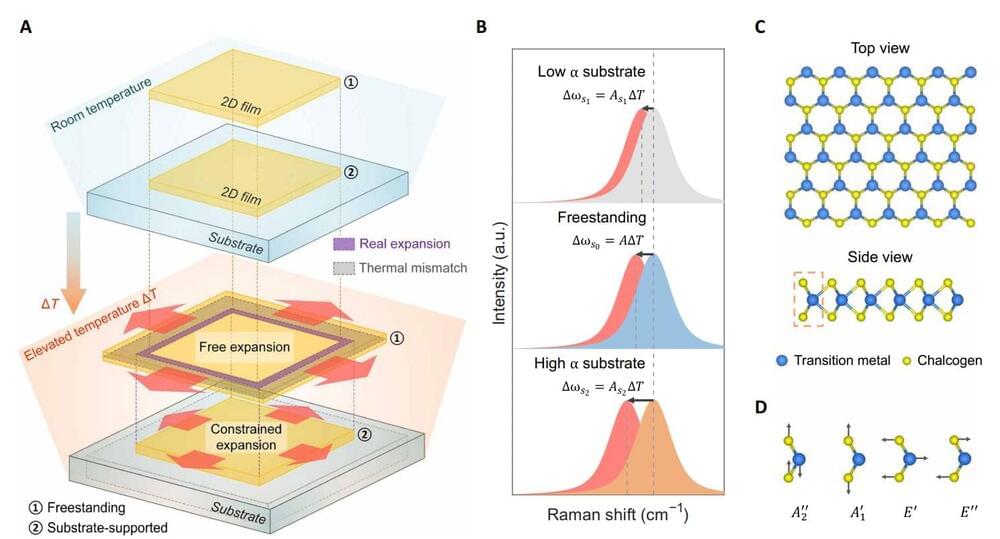

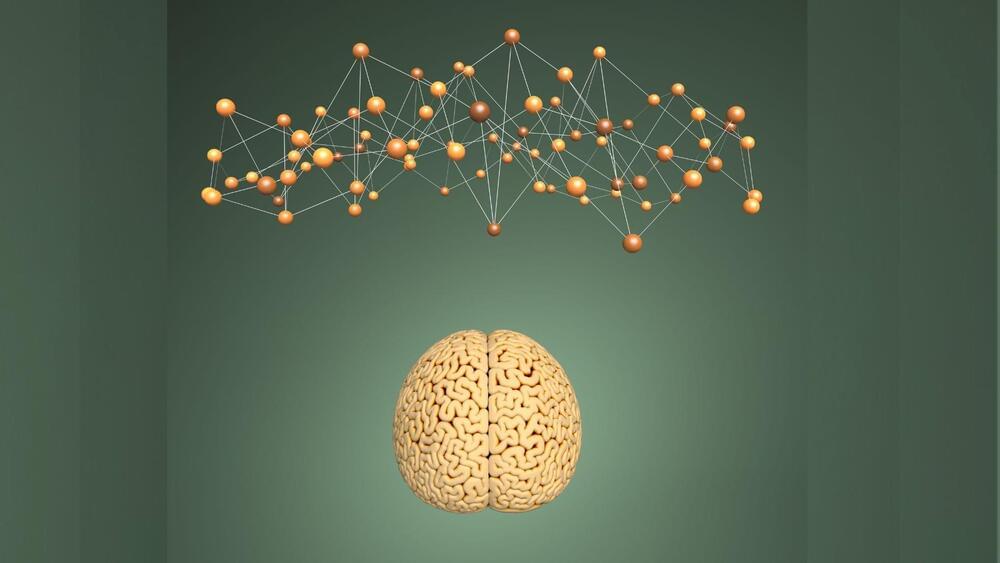

Combinatorial problems often arise in puzzles, origami, and metamaterial design. Such problems have rare collections of solutions that generate intricate and distinct boundaries in configuration space. Using standard statistical and numerical techniques, capturing these boundaries is often quite challenging. Is it possible to flatten a 3D origami piece without causing damage? This question is one such combinatorial issue. As each fold needs to be consistent with flattening, such results are difficult to predict simply by glancing at the design. To answer such questions, the UvA Institute of Physics and the research center AMOLF have shown that researchers may more effectively and precisely respond to such queries by using machine learning techniques.

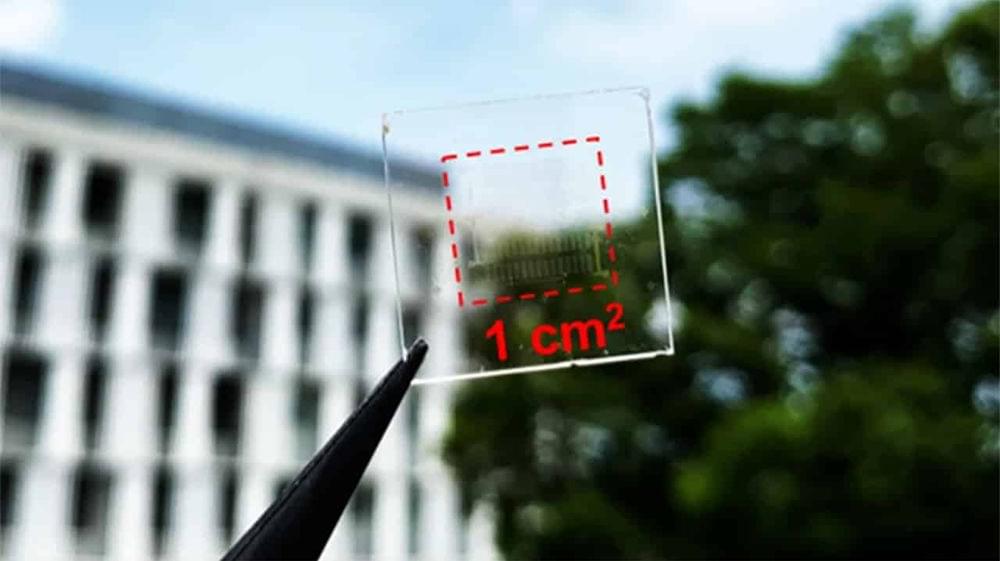

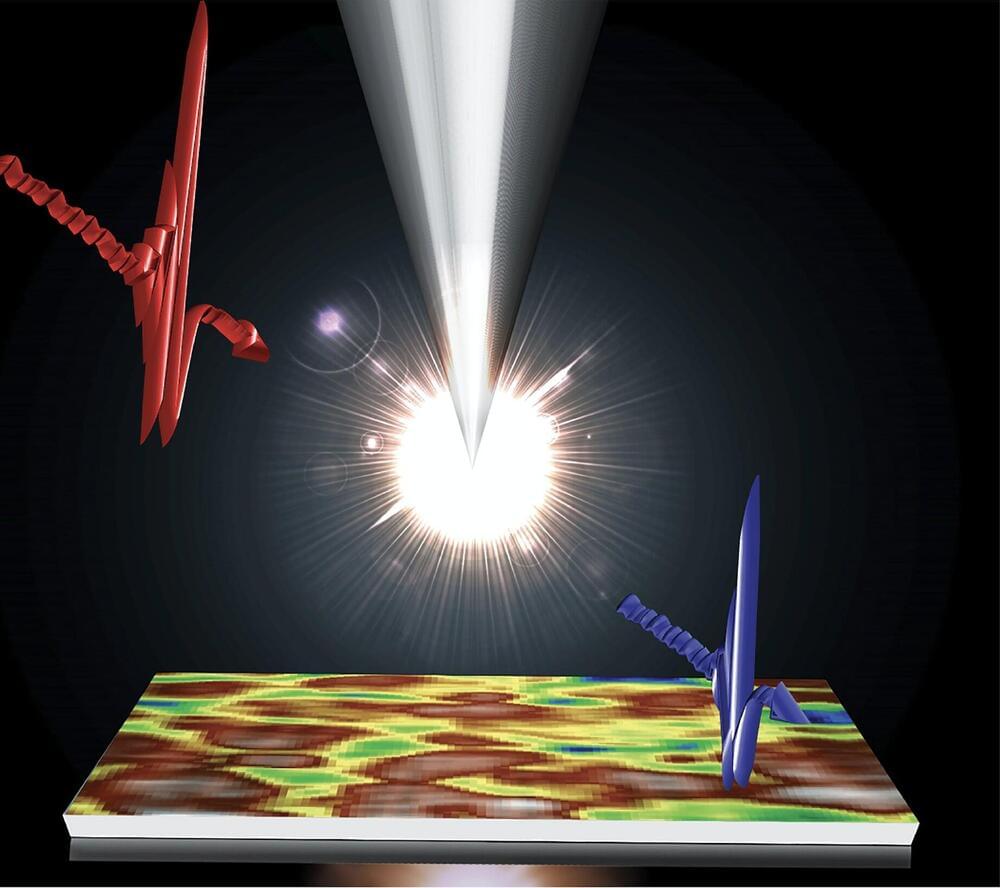

Despite employing severely undersampled training sets, Convolutional Neural Networks (CNNs) can learn to distinguish these boundaries for metamaterials in minute detail. This raises the possibility of complex material design by indicating that the network infers the underlying combinatorial rules from the sparse training set. The research team thinks this will facilitate the development of sophisticated, functional metamaterials with artificial intelligence. The team’s recent study examined the accuracy of forecasting the characteristics of these combinatorial mechanical metamaterials using artificial intelligence. Their work has also been published in the Physical Review Letters publication.

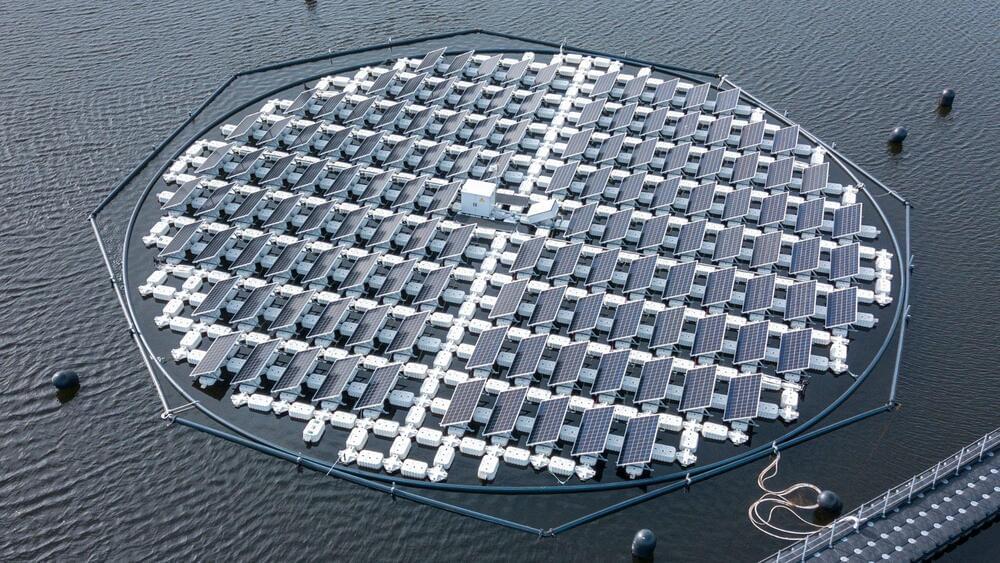

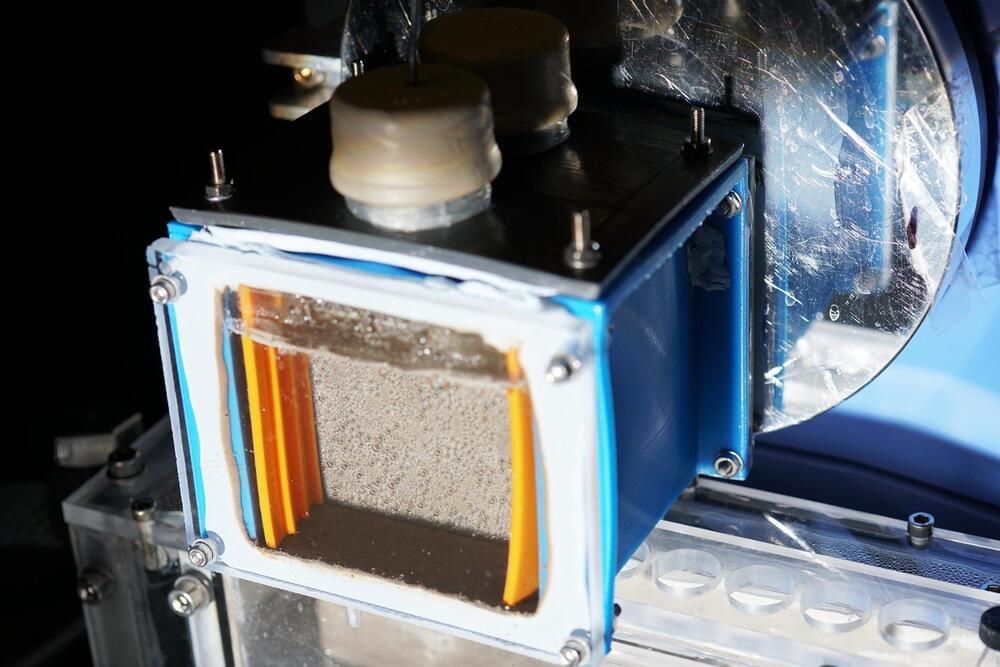

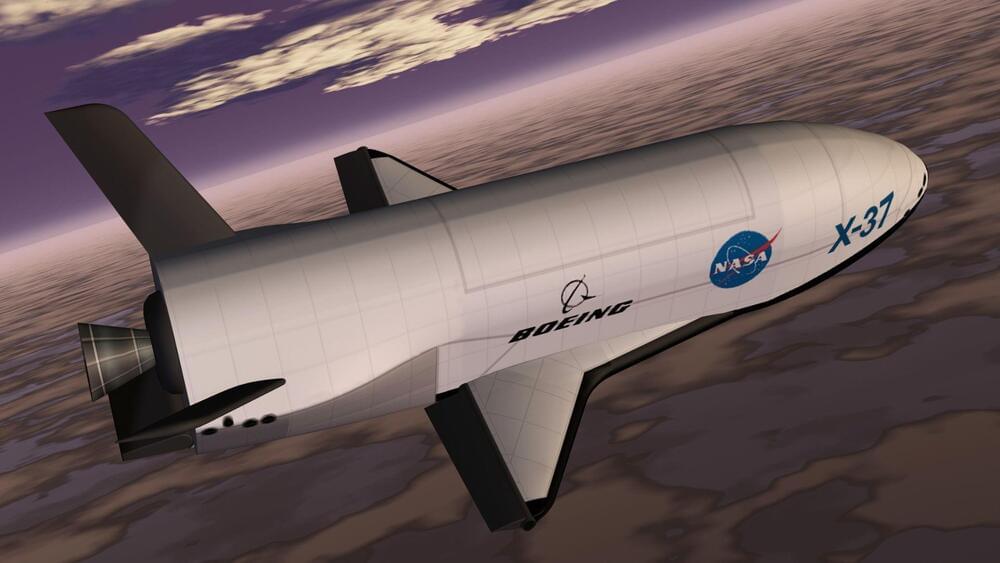

The attributes of artificial materials, which are engineered materials, are governed by their geometrical structure rather than their chemical makeup. Origami is one such metamaterial. The capacity of an origami piece to flatten is governed by how it is folded, i.e., its structure, and not by the sort of paper it is made of. More generally, the clever design enables us to accurately regulate a metamaterial’s bending, buckling, or bulging. This can be used for many different things, from satellite solar panels that unfurl to shock absorbers.