Houston oil field software firm Bluware has landed an artificial intelligence deal with British oil major BP.

Photo: Marc Morrison / ST

GUANGZHOU/TOKYO — Tech startups in Shenzhen, known as China’s Silicon Valley, are set to experience a range of outcomes as the novel coronavirus pandemic appears to near its end, with some seeing their businesses thrive while others face headwinds following significantly reduced investment.

AI and robot companies feel positive impact, while some face harsh climate.

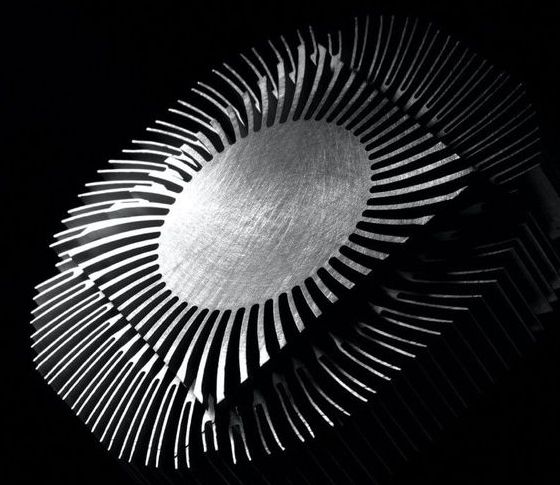

Graphcore, the four-year-old startup based in Bristol, England, has a chip that takes the kinds of math that a neural network processes and splits them across 1,216 tiny computers, each of which does its work in parallel with its brethren. The company believes its chip makes new kinds of AI possible.

A revolution is underway in the development of autonomous wireless sensors, low-power consumer electronics, smart homes, domotics and the Internet of Things. All the related technologies require efficient and easy-to-integrate energy harvesting devices for their power. Billions of wireless sensors are expected to be installed in interior environments in coming decades.

There aren’t many computer chips that you have to build a life support system for.

But when you’re combining actual living brain cells with inorganic silicon chips, you can’t feed them just electricity. You actually need to supply everything they would normally get in a fully biological body.

Why bother?

The Dawn of AI :

This video was made possible by Brilliant. Be one of the first 200 people to sign up with this link and get 20% off your premium subscription with Brilliant.org! https://brilliant.org/futurology

In the past few videos in this series, we have delved quite deep into the field of machine learning, discussing both supervised and unsupervised learning.

The focus of this video then is to consolidate many of the topics we’ve discussed in the past videos and answer the question posed at the start of this machine learning series, the difference between artificial intelligence and machine learning!

Thank you to the patron(s) who supported this video ➤

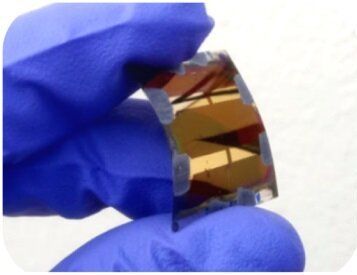

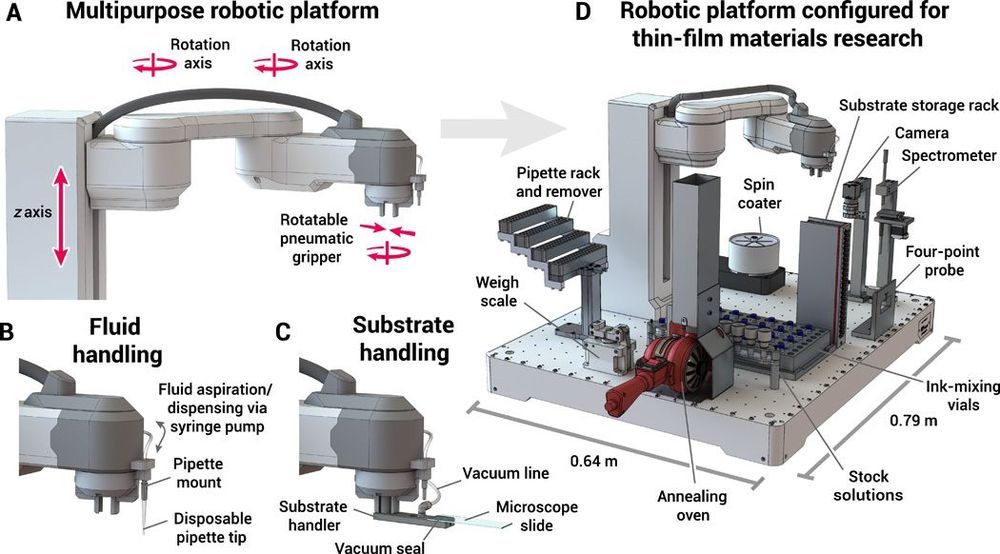

Discovering and optimizing commercially viable materials for clean energy applications typically takes more than a decade. Self-driving laboratories that iteratively design, execute, and learn from materials science experiments in a fully autonomous loop present an opportunity to accelerate this research process. We report here a modular robotic platform driven by a model-based optimization algorithm capable of autonomously optimizing the optical and electronic properties of thin-film materials by modifying the film composition and processing conditions. We demonstrate the power of this platform by using it to maximize the hole mobility of organic hole transport materials commonly used in perovskite solar cells and consumer electronics. This demonstration highlights the possibilities of using autonomous laboratories to discover organic and inorganic materials relevant to materials sciences and clean energy technologies.

Optimizing the properties of thin films is time intensive because of the large number of compositional, deposition, and processing parameters available (1, 2). These parameters are often correlated and can have a profound effect on the structure and physical properties of the film and any adjacent layers present in a device. There exist few computational tools for predicting the properties of materials with compositional and structural disorder, and thus, the materials discovery process still relies heavily on empirical data. High-throughput experimentation (HTE) is an established method for sampling a large parameter space (4, 5), but it is still nearly impossible to sample the full set of combinatorial parameters available for thin films. Parallelized methodologies are also constrained by the experimental techniques that can be used effectively in practice.

New machine learning methods bring insights into how lithium ion batteries degrade, and show it’s more complicated than many thought.

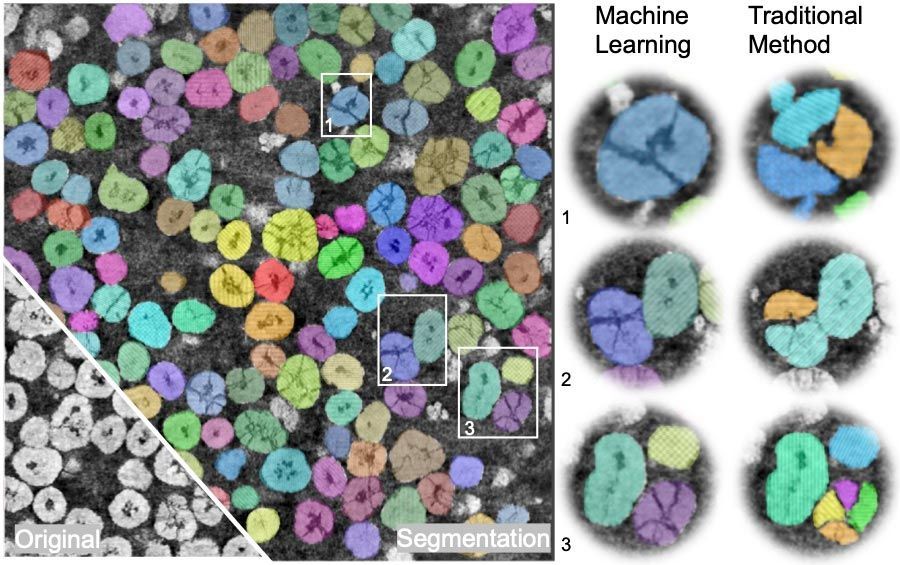

Lithium-ion batteries lose their juice over time, causing scientists and engineers to work hard to understand that process in detail. Now, scientists at the Department of Energy’s SLAC National Accelerator Laboratory have combined sophisticated machine learning algorithms with X-ray tomography data to produce a detailed picture of how one battery component, the cathode, degrades with use.

The new study, published this month in Nature Communications, focused on how to better visualize what’s going on in cathodes made of nickel-manganese-cobalt, or NMC. In these cathodes, NMC particles are held together by a conductive carbon matrix, and researchers have speculated that one cause of performance decline could be particles breaking away from that matrix. The team’s goal was to combine cutting-edge capabilities at SLAC’s Stanford Synchrotron Radiation Lightsource (SSRL) and the European Synchrotron Radiation Facility (ESRF) to develop a comprehensive picture of how NMC particles break apart and break away from the matrix and how that might contribute to performance losses.